Abstract

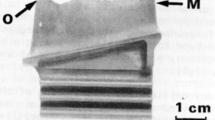

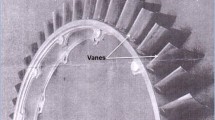

A failure investigation was conducted on a locomotive turbocharger-bearing sleeve. The failed bearing sleeve is made of 38CrMoAl steel and the external and internal surfaces are nitrided. The fracture took place at the transition fillet between the cylinder and the plate of the bearing sleeve. Multiple origin fatigue fracture was the dominant fracture mechanism. Serious wear took place on the external surface of the bearing sleeve. Metallurgical examination indicated that the depth of the nitrided layer on the surfaces of the bearing sleeve was generally below the acceptable limit set by the manufacturer. The thin nitrided layer on the external surface of cylinder was rapidly worn from the cylinder in service and the soft underlying matrix was exposed. At this point, the wear on the cylinder surface increased intensely and ultimately lead to increased friction between the external surface of the bearing sleeve and the bearing bush. Fatigue crack initiation occurred at the root fillet between the cylinder and the plate because of stress concentration in that area and the increased frictional forces. In addition, the insufficient nitrided layer depth in the fillet region facilitated propagation of fatigue crack. Appropriate nitriding process should be conducted on the bearing sleeve to obtain a sufficient hardening depth thus inhibiting surface wear and preventing fillet fatigue failure.

Similar content being viewed by others

References

Steel-Iron Parts-Determination of Nitrided Case Depth and Metallographic Examination of Nitriding Structure, China Standard, GB1542-89 (1990)

Das, C.R., Bhaduri, A.K., Ray, S.K.: Fatigue failure of a fillet welded nozzle joint. Eng. Fail. Anal. 10, 667–674 (2003)

Xi, N.S., Zhong, P.D., Huang, H.Q., Yan, H., Tao, C.H.: Failure investigation of blade and disk in first stage compressor. Eng. Fail. Anal. 7, 385–392 (2000)

Yu, Z., Xu, X., Guo, X.: Failure investigation of a locomotive turbocharger main shaft and bearing sleeve. J. Fail. Anal. Preven. 11, 167–174 (2011)

Alfares, M.A., Falah, A.H., Elkholy, A.H.: Failure analysis of a vehicle engine crankshaft. J. Fail. Anal. Preven. 7, 12–17 (2007)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Xu, X., Yu, Z. & Chen, Y. Fracture and Wear Failure of a Locomotive Turbocharger-Bearing Sleeve. J Fail. Anal. and Preven. 11, 672–678 (2011). https://doi.org/10.1007/s11668-011-9500-x

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11668-011-9500-x