Abstract

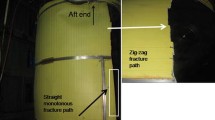

Aluminum alloys are frequently used as the preferred material for aerospace applications owing to their high-specific strength and ease of fabrication. In one such application, a torroidal-shaped water tank made of AFNOR 7020 (Al–4.5Zn–1.5Mg) alloy sheet and rings, stores water to provide for the initial run of a turbo pump and for the cooling of engine components. During the stage leak test, one of the water tanks leaked near the interconnecting ring welded to the shell. Detailed metallurgical investigations found that leakage was due to stress-assisted cracking, which was caused due to locked-in stresses introduced in the material during welding and to an inferior microstructure of the ring parent material. This article brings out the details of the investigations and recommends actions to avoid future failures.

Similar content being viewed by others

References

Jha, A.K., Sreekumar, K., Sinha, P.P.: Cracking of Al–Zn–Mg aluminium alloy nozzle weld of propellant storage tank—a metallurgical investigation. J. Fail. Anal. Prev. 9, 504–510 (2009)

Jha, A.K., Narayanan, P.R., Sreekumar, K., Sinha, P.P.: Cracking of Al–4.5Zn–1.5Mg aluminium alloy propellant tank—a metallurgical investigation. Eng. Fail. Anal. 17, 562–570 (2010)

Jha, A.K., Narayanan, P.R., Sreekumar, K.: Liquation cracking of Al–6.3Cu aluminium alloy propellant storage tank—a case study. Eng. Fail. Anal. 16, 1587–1596 (2009)

Jha, A.K., Narayanan, P.R., Sreekumar, K., Arumugham, S.: Failure of AA 2014 aluminum alloy bracket. Pract. Metallogr. (Ger.) 29(10), 534–542 (1992)

Jha, A.K., Murty, S.V.S.N., Jacob, E.: Metallurgical analysis of cracks on an aluminum alloy ring used in a satellite separation system. Eng. Fail. Anal. 9, 709–719 (2002)

Huang, C., Kou, S.: Liquation cracking in full penetration Al-Si weld. Weld. Res. 111S (2004)

Meletis, E.I.: Stress corrosion cracking properties of 2090 Al-Li alloy. In: Goel, V.S. (ed.) Corrosion Cracking, Conference Proceedings, p 315. American Society of Metals (1986)

Jha, A.K., Murty, S.V.S.N., Diwakar, V., Kumar, K.S.: Metallurgical analysis of cracking in weldment of propellant tank. Eng. Fail. Anal. 10(3), 265–273 (2003)

Sreekumar, K., John, K.M., Natrajan, A., Lakshmanan, T.S.: Metallurgical aspects of stress assisted failure in high strength aluminium alloy. Pract. Metallogr. 31, 586–595 (1994)

Acknowledgments

The authors are indebted to Shri P.S. Veeraraghavan, Director, VSSC for permission to publish this work.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Jha, A.K., Sreekumar, K. & Sinha, P.P. Cracking of AFNOR 7020 Aluminum Alloy Weld Joint of Water Tank for Satellite Launch Vehicle: A Metallurgical Investigation. J Fail. Anal. and Preven. 11, 603–610 (2011). https://doi.org/10.1007/s11668-011-9497-1

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11668-011-9497-1