Abstract

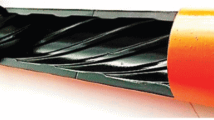

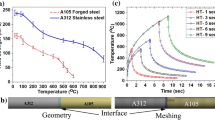

Surface cracks found on austenitic stainless steel piping after inductive bending into manifolds were shown to be caused by liquation cracking due to over heating. The cracked manifolds were dicarded and a new vendor was selected.

Similar content being viewed by others

References

Cross, C.E.: Private Communication. Federal Institute for Materials Research and Testing, Berlin, May 19, 2010

Cottrell, A.H., Swann, P.R.: Technical lessons of Flixborough. A metallurgical examination of the eight-inch line. Chem. Eng. 308, 266–274 (1976)

Hough, R.R., Rolls, R.: Creep fracture phenomena in iron embrittled by liquid copper. J. Mater. Sci. 6, 1493–1498 (1971)

Pohl, M.: Private Communication. Ruhr-Universität Bochum, Bochum, February 16, 2010

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Neidel, A., Riesenbeck, S. Hot Cracking in Inductively Bent Austenitic Stainless Steel Pipes. J Fail. Anal. and Preven. 11, 473–477 (2011). https://doi.org/10.1007/s11668-011-9478-4

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11668-011-9478-4