Abstract

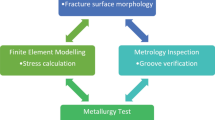

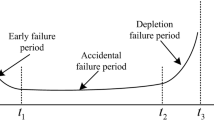

A failure analysis of steel shafts operating as roll components in a tube drawing machine was conducted. Visual inspection, optical microscopy, SEM fractography, and hardness testing were used as the principal analytical tools for the failure investigation. The findings showed that the failure mechanism is rotating bending fatigue under low stress–high stress concentration conditions. The primarily inadequate component design resulted in high stress concentration factors interacted with the soft annealed material used for the component and caused fatigue under the presence of fluctuating stresses.

Similar content being viewed by others

References

ASM Handbook: Failure Analysis and Prevention, vol. 11. ASM International, OH, USA (1992)

Pantazopoulos, G., Sampani, A., Tsagaridis, E.: Torsional failure of a knuckle joint of a universal steel coupling system during operation—a case study. Eng. Fail. Anal. 14(1), 73–84 (2007)

Pantazopoulos, G., Vazdirvanidis, A., Toulfatzis, A., Rikos, A.: Fatigue failure of steel links operating as chain links in a heavy duty draw bench. Eng. Fail. Anal. 16, 2440–2449 (2009)

Pantazopoulos, G., Vazdirvanidis, A.: Fractographic and metallographic study of spalling failure of steel straightener rolls. J. Fail. Anal. Preven. 8(6), 509–514 (2008)

Fonte, M., de Freitas, M.: Marine main engine crankshaft failure analysis: a case study. Eng. Fail. Anal. 16, 1940–1947 (2009)

Wulpi, D.J.: Understanding How Components Fail, 2nd edn. ASM International, Materials Park, OH (2000)

Sachs, N.W.: Practical Plant Failure Analysis. CRC Press/Taylor and Francis Group, Boca Raton, FL (2007)

Sachs, N.W.: Understanding the surface features of fatigue fractures: how they describe the failure cause and the failure history. J. Fail. Anal. Preven. 5(2), 11–15 (2005)

Totten, G.: Fatigue crack propagation. Adv. Mater. Process. 166(5), 39–41 (2008)

ASM Handbook: Atlas of Microstructures of Industrial Alloys, vol. 7, 8th edn. ASM International, OH (1973)

Jones, D.R.H.: Engineering Materials 3—Materials Failure Analysis. Pergamon Press, Oxford, UK (1993)

Harris, D., Jur, T.: Classical fatigue design techniques as a failure analysis tool. J. Fail. Anal. Preven. 9(1), 81–87 (2009)

Hamrock, B.J., Schmid, S.R., Jacobson, B.O.: Fundamental of Machine Elements, 2nd edn. McGraw Hill, Burr Ridge, IL (2006)

Shigley, J.E., Mishke, C.R.: Mechanical Engineering Design, 5th edn. McGraw Hill, New York (1989)

Collins, J.A.: Failure of Materials in Mechanical Design. Wiley, New York (1981)

Acknowledgments

The authors wish to express special thanks to Mr. A. Rikos and Mr. A. Toulfatzis for their valuable contribution to the completion of the experimental work.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Pantazopoulos, G., Zormalia, S. & Vazdirvanidis, A. Investigation of Fatigue Failure of Roll Shafts in a Tube Manufacturing Line. J Fail. Anal. and Preven. 10, 358–362 (2010). https://doi.org/10.1007/s11668-010-9369-0

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11668-010-9369-0