Abstract

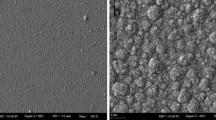

The 300 series stainless steels generally exhibit good corrosion resistance in common use. However, a premature fracture event caused by hydrogen embrittlement was encountered on 300 series stainless steels which was used as belt hanging chips in a tin plating process for the chip lead frame. The cause of the fracture was carefully studied. A metallurgical microscope and photoelectric direct reading spectrometer were used to examine the metallographic structures and chemical compositions of the matrix material. A scanning electron microscope and energy disperse spectroscope were also applied to analyze the micro morphologies and micro-area composition of the fracture. Meanwhile, the chemistry and hydrogen content of the process media were inspected by ion chromatography and hydrogen analyzer. In addition, the finite element method was employed to simulate the effect on the belt from the service conditions. The analysis results revealed that the unqualified material selection, the aggressive media, and the inappropriate technological parameters were the main causes of the failure. Furthermore, the mechanisms of hydrogen embrittlement were discussed, and countermeasures and suggestions were put forward.

Similar content being viewed by others

References

Shanghai Jiao Tong University, Analysis of Metal Fracture Surface. National Defense Industry Press (1979) (in Chinese)

Han, G., He, J., Fukuyama, S., Yokogawa, K.: Effect of stain-induced martensite on hydrogen environment embrittlement of sensitized austenitic stainless steels at low temperatures. Acta Mater. 46(13), 4559–4570 (1998)

Ji, G.: World Standard Steel Handbook. Standards Press of China (2004) (in Chinese)

Kuromoto, N.K., Guimarães, A.S., Lepienski, C.M.: Superficial and internal hydrogenation effects on the fatigue life of austenitic steels. Mater. Sci. Eng. A 381(1–2), 216–222 (2004)

Perng, T.P., Altstetter, C.J.: Hydrogen permeation and diffusion in cryoformed AISI 301 stainless steel. Scripta Metall. 18(1), 67–70 (1984)

Singh, D.D.N., Ghosh, R., Singh, B.K.: Fluoride induced corrosion of steel rebars in contact with alkaline solutions, cement slurry and concrete mortars. Corr. Sci. 44(8), 1713–1735 (2002)

Ju, C.P., Rigsbee, J.M.: The role of microstructure for hydrogen-induced blistering and stepwise cracking in a plain medium carbon steel. Mater. Sci. Eng. 74(1), 47–53 (1985)

Wang, Y.-F., Yang, Z.-G.: Finite element analysis of residual thermal stress in ceramic-lined composite pipe prepared by centrifugal-SHS. Mater. Sci. Eng. A 460–461, 130–134 (2007)

Wang, Y.-F., Yang, Z.-G.: A coupled finite element and meshfree analysis of erosive wear. Tribol. Int. 42(2), 373–377 (2009)

Wang, Y.-F., Yang, Z.-G.: Finite element model of erosive wear on ductile and brittle materials. Wear 265(5–6), 871–878 (2008)

Folkhard, E.: Welding Metallurgy of Stainless Steels. Chemical Industry Press (2004) (in Chinese)

Wang, C.Q., Yu, Y., Fang, Y., Li, T.J.: In situ observation of carbide precipitation and dissolution in strip cast 304 stainless steel. J. Iron Steel Res. 19(9), 42–46 (2007) (in Chinese)

Bungardt, K., Kunze, E., Horn, E.: Untersunchungen über den aufbau des systems eisen-chrom-kohlenstoff. Arch Eisenbüttenwes 29, 193–203 (1958)

Ji, L.-N., Yang, Z.-G., Liu, J.-S.: Failure analysis on blind vias of PCB for novel mobile phones. J. Fail. Anal. Preven. 8(6), 524–532 (2008)

Gong, Y., Cao, J., Meng, X.-H., Yang, Z.-G.: Pitting corrosion on 316L pipes in terephthalic acid (TA) dryer. Mater. Corros. 60(11), 899–908 (2009)

Masuku, E.S., Mileham, A.R., Hardisty, H., Bramley, A.N., Johal, C., Detassis, P.: A finite element simulation of the electroplating process. CIRP Ann. Manuf. Tech. 51(1), 169–172 (2002)

An, M.Z.: Electroplating Theory and Technology. Harbin Institute of Technology Press (2004) (in Chinese)

Chemical Machinery Research Institute of Ministry of Chemical Industry: Manual of Corrosion and Protection. Chemical Industry Press (1989) (in Chinese)

Li, D.: Electrochemical Theory (Rev. ed.). Beijing University of Aeronautics and Astronautics Press (1999) (in Chinese)

Michler, T., Naumann, J.: Coatings to reduce hydrogen environment embrittlement of 304 austenitic stainless steel. Surf. Coat. Technol. 203(13), 1819–1828 (2009)

Borchers, C., Michler, T., Pundt, A.: Effect of hydrogen on the mechanical properties of stainless steels. Adv. Eng. Mater. 10(1–2), 11–23 (2008)

Nelson, H.G.: Testing for Hydrogen Environment Embrittlement: Primary and Secondary Influences, Hydrogen Embrittlement Testing, pp. 152–170. ASTM Special Technical Publication (1974)

Ogorodnikova, O.V.: Comparison of hydrogen gas-, atom- and ion-metal interactions. J. Nucl. Mater. 277(2–3), 30–42 (2000)

Woodtli, J., Kieselbach, R.: Damage due to hydrogen embrittlement and stress corrosion cracking. Eng. Fail. Anal. 7(6), 427–450 (2000)

Acknowledgments

The work was supported by both Advanced Semiconductor Engineering (ASE) Group and Shanghai Leading Academic Discipline Project (Project Number: B113).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Gu, YS., Gong, Y. & Yang, ZG. Hydrogen Embrittlement on High-Speed Stainless Steel Belts Used for Tin Plating Chip Lead Frame. J Fail. Anal. and Preven. 10, 399–407 (2010). https://doi.org/10.1007/s11668-010-9359-2

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11668-010-9359-2