Abstract

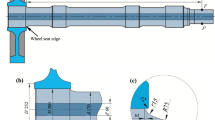

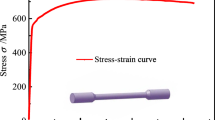

In the present work, the fatigue behavior of an axle was analyzed using modeling and experimental approaches. A failed axle was used for experimental studies. The experimental results were then analyzed in order to model and predict the fatigue life of axle. The three-dimensional finite element analysis was used to simulate the fatigue behavior of axle. The growth of a machining defect, 2 μm initial crack length, was simulated versus applied cycles. The changes in the stress intensity factor as a function of crack length were modeled as well. The model predicted that after about 5 × 108 cycles there was an abrupt increase in the crack length, reaching a critical value of about 65 mm at around N f = 5 × 109 cycles, indicating that the longer the crack, the higher its growth will be. The experimental results were then compared with the modeling predictions. It is shown that the latter are in a good agreement with the former. The results obtained in this study do give a basis for evaluation of single scratch or notch produced by improper machining.

Similar content being viewed by others

References

McEvily, A.J.: Metal Failures: Mechanisms, Analysis, Prevention. Wiley, New York (2002)

Nishida, S.: Failure Analysis in Engineering Applications. Butterworth Heinemann, London (1992)

Mousavi zadeh, S.M., Dehghani, K., Pouranvari, M.: Failure analyses of automatic coupler SA-3 in railway carriage. Eng. Fail. Anal. 14, 903–912 (2007)

Murakami, Y.: Metal Fatigue: Effects of Small Defects and Nonmetallic Inclusions. Elsevier Science Ltd., Oxford, UK (2002)

Berns, H., Weber, L.: Influence of residual stresses on crack growth. Proceedings of the 2nd International Conference on Impact Treatment Processes, 22–26 September, Cranfield (1986)

Yamada, Y., Koarai, J., Kawaguchi, Y., Ishigami, O., Ibaraki, N.: Influence of undefonnable nonmetallic inclusions on fatigue life. Trans. Jpn. Soc. Spring Res. 31, 1–8 (1986)

Ozone, T., Hijikata, N.: Effect of processes on rotating bending fatigue strength of Si-Cr valve spring wire. Trans. Jpn. Soc. Spring Res. 33, 53–58 (1988)

Tange, A., Akutsu, T., Takamura, N.: Relationship between residual stress by shot peening and fatigue growth life of spring steel. Proceedings of the 1990 Spring Annual Meeting, Jpn. Soc. Spring Res. 1–6 (1990)

Beretta, S., Ghidini, A., Lombardo, F.: Fracture mechanics and scale effects in the fatigue of railway axles. Eng. Fract. Mech. 72, 195–208 (2005)

Zerbst, U., Vormwald, M., Andersch, C.: The development of a damage tolerance concept for railway components and its demonstration for a railway axle. Eng. Fract. Mech. 72, 209–239 (2005)

Hirakawa, K., Toyamo, K., Kubota, M.: The analysis and prevention of failure in railway axle. Int. J. Fatigue 20, 135–144 (1998)

McQuaid, J., Jones, N.: A re-examination of Andrews’ research on impact resistance of railway axles. Int. J. Impact Eng. 22, 727–738 (1999)

Metals Handbook, 10th edn., vol. 11, Failure Analysis, Section of Shafts Failure, ASM Publication (1996)

Alihosseini, H., Dehghani, K.: Fatigue life analysis in railway axle. 10th Iranian Metallurgist Congress, Mashad, Iran, pp. 30–36 (2006)

ASTM Standards, ASTM E8-M: Standard Test Method for Tension Testing of Metallic Materials (1995)

International Railway Standards, UIC Code 811-1 (1983)

Standard Test Method for Plane-Strain Fracture Toughness of Metallic Materials, E 399-90. Annual Book of ASTM Standards, Metal Test Methods and Analytical Procedures, vol. 3.01, p. 412 (1995)

ASTM Standards, ASTM E647-95, Standard Test Method for Measurement of Fatigue Crack Growth Rates (1995)

Paris, P.C., Erdogan, F.: J. Basic Eng. 85, 528–535 (1963)

Metals Handbook, 10th edn., vol. 19, Fatigue and Fracture, ASM Publication (1996)

Tada, H., Paris, P.C., Irwin, G.R.: The stress analysis of cracks handbook, 3rd edn. ASME Press, New York (2000)

Couroneau, N., Royer: Simplified model for the fatigue growth analysis of surface cracks in round bars under mode I. Int. J. Fatigue 20, 711–718 (1998)

M. da Fonte, M. de Freitas: Stress Intensity Factors for semi-elliptical surface cracks in round bars under bending and torsion. Int. J. Fatigue 21, 457–463 (1999)

Couroneau, N., Royer, J.: Simplifying hypotheses for the fatigue growth analysis of surface cracks in round bars. Comput. Struct. 77, 381–389 (2000)

Brabie, G.: An analysis of the shearing stresses distribution on the cross-section of the twisted round bars. J. Mater. Process. Technol. 142, 224–230 (2003)

Lina, X.B., Smith, R.A.: Finite element modeling of fatigue crack growth of surface cracked plates. Part II: crack shape change. Eng. Fract. Mech. 63, 523–540 (1999)

Lina, X.B., Smith, R.A.: Finite element modeling of fatigue crack growth of surface cracked plates. Part III: stress intensity factor and fatigue crack growth life. Eng. Fract. Mech. 63, 541–556 (1999)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Alihosseini, H., Dehghani, K. Modeling and Failure Analysis of a Broken Railway Axle: Effects of Surface Defects and Inclusions. J Fail. Anal. and Preven. 10, 233–239 (2010). https://doi.org/10.1007/s11668-010-9340-0

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11668-010-9340-0