Abstract

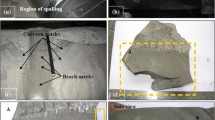

Tapered roller bearings, which are also known as angular-contact bearing, are suitable for supporting radial and axial loads. The more frequent types of defects in such bearings are caused by contact fatigue in these machine components, and this examination focuses on a contact fatigue failure in a tapered rolling bearing. The examination included visual inspection, microscopic analysis (optical and scanning electron microscope), and microhardness measurements. These measurements were conducted to help understand the failure mechanisms. Based on the results of visual examination and microstructure and fracture surface analysis, it was determined that the tapered roller bearing failed by contact fatigue that was caused by overloading of the bearing.

Similar content being viewed by others

References

ASM Metals Handbook: Failure of Rolling-Element Bearings, vol. 11, Failure Analysis and Prevention, 9th edn, p. 490. American Society for Metals, Metals Park, OH (1986)

Ferreira, J.L.A., Balthazar, J.C., Araujo, A.P.N.: An investigation of rail bearing reliability under real conditions of use. Eng. Fail. Anal. 10, 745–758 (2003)

Carter, T.L., Zaretsky, E.V., Anderson, W.J.: Effect of Hardness and Other Mechanical Properties on Rolling-contact Fatigue Life of Four High-temperature Bearing Steels, NASA TN D-270. National Aeronautics and Space Administration, Washington (1996)

Johnson, K.L.: Contact Mechanics. Cambridge University Press, London (1985)

Zaretsky, E.V., Parker, R.J., Anderson, W.J.: Component hardness differences and their effect on bearing life. Trans. ASME, J. Lubr. Tech. 89(1), 47–62 (1967)

Flasker, J., Fajdiga, G., Glodez, S., Hellen, T.K.: Numerical simulation of surface pitting due to contact loading. Int. J. Fat. 23, 599–605 (2001)

Aslantas, K., Tasgetiren, S.: Modelling of spall formation in a plate made of austempered ductile iron having a subsurface-edge crack. Comput. Mater. Sci. 29, 29–36 (2004)

Tasgetiren, S., Aslantas, K.: A numerical study of the behaviour of surface cracks under dry-sliding conditions. Mater. Des. 24, 273–279 (2003)

Blake, J.W., Cheng, H.S.: A surface pitting life model for spur gears: Part I—Life prediction. J. Tribol. 113, 712–718 (1991)

Blake, J.W., Cheng, H.S.: A surface pitting life model for spur gears: Part II—Failure probability prediction. J. Tribol. 113, 719–724 (1991)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kayalı, Y., Ucun, I. & Aslantaş, K. Contact Fatigue Failure of a Tapered Roller Bearing Used in a Lorry Wheel. J Fail. Anal. and Preven. 9, 288–294 (2009). https://doi.org/10.1007/s11668-009-9233-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11668-009-9233-2