Abstract

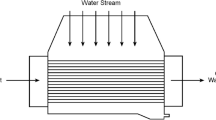

A brackish water pump impeller was replaced after 4 years of service, while its predecessor lasted over 40 years. The subsequent failure investigation determined that the nickel–aluminum bronze (NAB) impeller was not properly heat treated, which made the impeller susceptible to aluminum dealloying. The dealloying corrosion was exacerbated by erosion, because the pump was slightly oversized. This investigation recommended proper heat treatment of NAB alloys that are to be used in salt water or brackish service. Additionally, the investigation recommended closer evaluation of new pumps to ensure that they are properly sized.

Similar content being viewed by others

References

Michels, H.T., Kain, R.M.: Effect of composition and microstructure on the seawater corrosion resistance of nickel–aluminum bronze. Paper No.03262, NACE Corrosion/2003, NACE International, Houston, Texas

R.J. Ferrara, T.E. Caton, Review of dealloying of cast aluminum bronze and nickel–aluminum bronze alloys in sea water service. Mater. Perform. 21(2), 30–34 (1982)

ASTM B148–97: Standard Specification for Aluminum-Bronze Castings. ASTM International, West Conshohocken, PA (Reapproved 2003)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Olszewski, A.M. Dealloying of a Nickel–Aluminum Bronze Impeller. J Fail. Anal. and Preven. 8, 505–508 (2008). https://doi.org/10.1007/s11668-008-9181-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11668-008-9181-2