Abstract

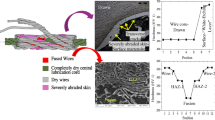

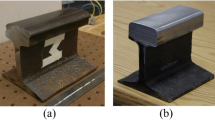

A locked coil track rope (LCTR) is essentially composed of wires (round and rail-shaped) laid helically in different layers. These wire ropes are sometimes used in conveyors carrying empty and loaded buckets in mining areas. During service, such wire ropes may fail prematurely due to disintegration/failure of individual groups of wires. To understand the genesis of LCTR wire failures, a detailed metallurgical investigation of failed rope wires was made and included visual examination, optical microscopy, scanning electron microscopy (SEM), and electron probe microanalysis (EPMA). Two types of failed wires were investigated; one is from a 40 mm diameter locked coil track rope and the other from a 53 mm locked coil track rope. Optical microscopy of failed round wires in the 53 mm diameter rope clearly revealed fully decarburized layers at the surface and a few grain-boundary cracks. From the location of the failure, it was clear that apart from static tensile loads, the wire ropes had been subjected to bending and unbending loads near the saddle, as fully loaded or empty buckets traveled access the conveyor. The SEM studies confirmed that the fracture had been caused by initiation of fatigue cracks in the decarburized zone under conditions of repeated bending and unbending stresses superimposed on the static tensile load.

Similar content being viewed by others

References

Sharp, G.A.: Steel wire for ropes. In: Dove, A.B. (ed.) Steel Wire Handbook, vol. 3, pp. 77–94. The Wire Association Inc., Branford, CT (1972)

Lankford, W.T., Jr., Samways, N.L., Craven, R.F., McGannon, H.E. (eds.): The manufacture of steel wire and steel wire products, The Making, Shaping and Treating of Steel, 10th ed., pp. 961–1016. United States Steel, Pittsburgh, PA (1985)

Dove, A.B. (ed.): Production of wire rod, Steel Wire Handbook, vol. 1, pp. 9–92. The Wire Association Inc., Branford, CT (1975)

Lewis, D.: Patenting. In: Dove, A.B. (ed.) Steel Wire Handbook, vol. 2, pp. 65–83. The Wire Association Inc., Branford, CT (1969)

Ryder, D.A.: General practice in failure analysis, Failure Analysis and Prevention, vol. 11, Metals Handbook, pp. 15–46. American Society for Metals (1986)

Hutchings, F.R., Unterweiser, P.M.: Service related failures, Failure Analysis—The British Engine Technical Reports, pp. 307–386. American Society for Metals, Metals Park, OH (1981)

Barer, R.D., Peters, B.F.: Wire ropes, Why Metals Fail, pp. 218–223. Gordon & Breach Science Publishers, New York, NY (1982)

Dhua, S.K., Ray, A., Jha, S.: Metallurgical investigation of locked coil wire rope samples fractured during service. Steel India 23(2), 40–42 (2000)

Ray, A., Dhua, S.K., Mishra, K.B., Jha, S.: Microstructural manifestation of fractured Z-profile steel wires on the outer layer of a failed locked coil wire rope. Pr. Fail. Anal. 3(4), 33–37 (2003)

Smith, C.O.: Failure analysis, The Science of Engineering Materials, pp. 513–533. Prentice Hall, Inc., Englewood Cliffs, NJ (1979)

Acknowledgment

The authors express their gratitude for the support and encouragement received from the management of the Research and Development Centre for Iron and Steel (RDCIS), Steel Authority of India Limited, Ranchi, India, during the course of experimental work. Thanks are expressed to the personnel of the metallography laboratory, notably Shri C. B. Sharma, Shri B.B. Patra, and Shri J. Guria at RDCIS for their help in their investigation. Thanks are also due to Shri B. Khalko for typing out the manuscript in short time.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Dhua, S.K., Singh, C.D. & Ray, A. Metallurgical Investigation of Failed Locked Coil Track Ropes Used in a Mining Conveyor. J Fail. Anal. and Preven. 8, 515–523 (2008). https://doi.org/10.1007/s11668-008-9171-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11668-008-9171-4