Abstract

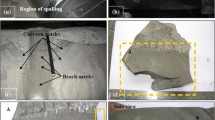

Spalled fragments from work rolls of a steel bar straightening machine were received for failure analysis. Visual inspection coupled with optical and scanning electron microscopy (SEM) were used as the principal analytical techniques for the investigation. Fractographic observations clearly revealed the presence of a characteristic fatigue crack propagation pattern (beach marks) and radial chevron marks indicating the occurrence of final overload through a brittle intergranular fracture mode. The collected evidence suggests strongly that surface-initiated cracks propagated by fatigue mechanism led to spalling, resulting therefore in severe work roll damage and subsequently high machine downtime and maintenance costs.

Similar content being viewed by others

References

Fractography, vol. 12, ASM Handbook, ASM International, OH, USA (1992)

Rolls for Metalworking Industries, Iron and Steel Society (ISS), Warrendale, PA (2002)

Venugopal Reddy, A.: Investigation of Aeronautical and Engineering Failures, CRC Press (2004)

Prasad, M.S., Dhua, S.K., Singh, C.D., Ray, A.: Genesis of spalling in tandem mill work-rolls: some observations in microstructural degeneration. J. Fail. Anal. Preven. 5(6), 30–38 (2005)

Ray, A., Prasad, M.S., Barhai, P.K., Mukherjee, S.K.: Metallurgical investigation of prematurely failed hot-strip mill work-rolls: some microstructural observations. J. Fail. Anal. Preven. 4(3), 58–66 (2004)

Prasad, M.S., Ray, A., Dhua, S.K.. Avtar, R., Jha, S.: Premature failure of work-rolls in tandem mill: Some microstructural revelations. J. Fail. Anal. Preven. 4(3), 67–72 (2004)

Wulpi, D.: Understanding How Components Fail, 2nd edn. ASM International (2005)

Azevedo, C.R.F., das Neves, J.C.K., Sinatora, A.: Failure analysis of belt/roll tribological pair used for the production of eucalypt fiber panels. Eng. Fail. Anal. 15, 165–181 (2008)

BS EN ISO 6507-1:2005, “Metallic Materials. Vickers Hardness Test. Part 1: Test Method.” ISO, Geneva, Switzerland

Psyllaki, P., Papadimitriou, K., Pantazopoulos, G.: Failure modes of liquid nitrocarburized and heat treated tool steel under monotonic loading conditions. J. Fail. Anal. Preven. 6(6), 13–18 (2006)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Pantazopoulos, G., Vazdirvanidis, A. Fractographic and Metallographic Study of Spalling Failure of Steel Straightener Rolls. J Fail. Anal. and Preven. 8, 509–514 (2008). https://doi.org/10.1007/s11668-008-9170-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11668-008-9170-5