Abstract

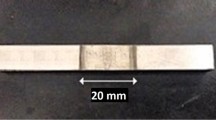

Silicomanganese grade billets are the most commonly used steels for manufacture of automobile leaf springs. However, Cr-Mn-B grade steel known by trade name of SUP 11A grade is replacing the conventional silicomanganese grades such as 60Si7 or 65Si7 steels because it has become a competitive alternative in the market. Three heats of SUP11A grade spring steel were made through BOF-VAD-CC route and continuously cast into 125 × 125 mm billets. Some of the billets contained blowholes and piping. Rolling of selected billets into 85 × 15 mm flats revealed occasional slivers, seams, and a few shallow hairline surface cracks. A detailed metallurgical investigation was carried out to understand the genesis of these defects. A pearlite-free ferritic microstructure near the cracks combined with the presence of dispersed inclusions resulting from internal oxidation in the vicinity of cracks and the presence of scales within the shallow discontinuous short-length longitudinal cracks indicated that these defects resulted from pre-existing subsurface blowholes lying within 1 mm of billet surface. Reduction of the gas content of liquid steel in the mold, optimization of electromagnetic stirring (EMS) current, and control of superheat are some of the broad measures identified to improve the cast quality of SUP 11A spring steel billets and minimize the rejection of rolled flats.

Similar content being viewed by others

References

Kern, R.F., Suess, M.E. (eds.): Steel Selection, A Guide for Improving Performance and Profits (Chapter 12), p. 223. Wiley-Interscience, New York (1978)

Method for determination of inclusion content in steel by macroscopic method (first revision), IS 4163, Bureau of Indian Standards, New Delhi (1982)

Standard Method of Macroetch Testing Steel Bars, Billets, Blooms and Forgings, ASTM E 381 – 01 (2006)

Birat, J.P., Chone, J.: Electromagnetic stirring on billet, bloom and slab continuous casters, state of the art in 1982. In: Moore, J.J. (ed.) Continuous Casting Volume 3—The Application of Electromagnetic Stirring (EMS) in the Continuous Casting of Steel, p. 21. Iron & Steel Society of AIME (1984)

Moore, J.J., Shah, N.A.: A review of the effects of electromagnetic stirring (EMS) in continuously cast steels. In: Moore, J.J. (ed.) Continuous Casting Volume 3—The Application of Electromagnetic Stirring (EMS) in the Continuous Casting of Steel, p. 35. Iron & Steel Society of AIME (1984)

Tzavaras, A.A.: Solidification control by electromagnetic stirring—State of art. In: Moore, J.J. (ed.) Continuous Casting Volume 3—The Application of Electromagnetic Stirring (EMS) in the Continuous Casting of Steel, p. 47. Iron & Steel Society of AIME (1984)

Adachi, T., Mizutani, M., Kimura, K.: Application of electromagnetic stirrers. In: Moore, J.J. (ed.) Continuous Casting Volume 3—The Application of Electromagnetic Stirring (EMS) in the Continuous Casting of Steel, p. 79. Iron & Steel Society of AIME (1984)

Scheil, E.: Z. Metallkde. 34, 70 (1942)

Samarasekera, I.V., Chow, C.: Continuous casting of steel billets. In: Cramb, A.W. (ed.) The Making, Shaping and Treating of Steel, 11th edn., Casting Volume (Chapter 17). AISE Steel Foundation, Pittsburgh, PA (2003)

Acknowledgments

The authors are grateful to the management of RDCIS and DSP for encouragement and support. Invaluable help rendered by Mr. K. Patwari, Mr. B.B. Reddy, and Mr. S.R. Sarkar during heat making and casting is acknowledged. Authors are thankful to Mr. C.B. Sinha and Dr. S.S. Dutta for coordination with plant and active support during different stages of planning, production, and dispatch. Fruitful technical discussions with Dr. Niladri Sen and Dr. C.D. Singh is acknowledged with pleasure. Keen interest and support provided by Dr. S.K. Chaudhuri, GM(P), RDCIS, and Sri A. Bhattacharyya, retired GM(RCL), DSP are gratefully acknowledged. We are indebted to application engineers, Sri S. Bhattacharyya, Sri N.K. Mehta, and Sri G.K. Sodani for their painstaking technical help during performance trials. Help received from Sri R.R. Storte, Sri Abhishekh Sinha, and Smt. Mausumi Bhattacharyya in coordinating the trials at customers’ end is acknowledged with pleasure.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kumar, S., Kumar, V., Nandi, R.K. et al. Investigation into Surface Defects Arising in Hot-Rolled SUP 11A Grade Spring Billets. J Fail. Anal. and Preven. 8, 492–497 (2008). https://doi.org/10.1007/s11668-008-9169-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11668-008-9169-y