Abstract

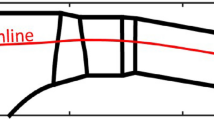

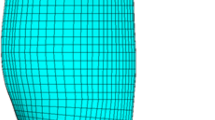

At Sunoco Chemicals in LaPorte, Texas, multiple resonant conditions exist on the skid and bearing support structure of an overhung fan. These are excited by the fan shaft speed and harmonics, as well as the fan blade passing frequency. The skid has modes in two planes on both long sections of channel, as well as modes on the two fan-side cross beams. The channel and angle supporting the motor also experience a resonant condition. The bearing support has modes on all five sides of the box. Most significant of these, however, are the right-hand and left-hand sides when viewed from the sheave end of the fan shaft. In addition to experiencing multiple resonances, there was virtually no damping present in the system. Calculations made from several different impact test ring-downs revealed damping factors less than 1%. The result of a small damping coefficient is that amplification at resonance is extremely large. At 1% damping, amplification factors can approach 100:1. By increasing damping to 10%, amplification can be reduced to 3:1. From data collected, we calculated that the existing isolation system does no better than 30% isolation. Proper isolation is 90–97%. As a result of these problems, we recommended the following: (i) Fill the interior of the skid structure with epoxy grout. This will eliminate the skid natural frequencies in the operating range, and raise its damping factor to nearly 10%. (ii) Add a “torsion box” type stiffening system to the bearing support box. Also, add a piece of angle iron to the front and back edges of the box in order to secure it to the skid. These changes will raise its lowest natural frequency from 100 to 450 Hz, well above the operating frequencies, including blade passing frequency. (iii) Modify the exterior of the skid to accommodate four isolation springs, specified to bring the vibration isolation to 97%. This will also reduce the dynamic load passed from the fan to the building steel from nearly 20,000 pounds to as low as 173 pounds. This reduction is dynamic load will more than make up for the additional 1,400 pounds static load due to the grout addition, steel modifications, and springs.

Similar content being viewed by others

Author information

Authors and Affiliations

Corresponding author

Additional information

Based on the article of the same title published in Integration of Machinery Failure Prevention Technologies into Systems Health Management, Proceedings of the 61st Meeting of the Society for Machinery Failure Prevention Technology, Society for Machinery Failure Prevention Technology, 2007, pp. 261–277. Reprinted with permission.

Rights and permissions

About this article

Cite this article

Stansloski, M. Analysis and Redesign Report for Overhung Fan. J Fail. Anal. and Preven. 8, 103–110 (2008). https://doi.org/10.1007/s11668-008-9127-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11668-008-9127-8