Abstract

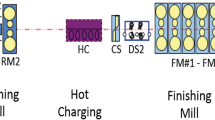

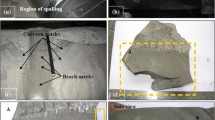

The paper presents the failure analysis of tungsten carbide rolls for the Wire and Rod Mill (WRM) and establishes the failure reasons and the corrective and preventive actions taken to improve roll performance. A sharp continuous increase in failure rate and decrease in average time between failure (ATBF) was observed during 2001 to 2004. The increase in premature failure of these rolls (16 rolls in 2003 and 38 rolls in 2004) raised the cost of operations. Due to unscheduled stoppage of the mill after roll failures, the unplanned mill delays also increased, causing production losses. The analysis revealed significant increase in premature failure of rolls in the finishing stands 19, 22, 23, and 24 and prefinishing stand 14. The primary causes of such failures were faulty roll cooling and roll mounting and accumulation of cobbles. Implementation of modified cooling headers, a calibrated gage to monitor hydraulic pressure during roll mounting, and eddy current inspection resulted in decreasing the trend in roll failure and increasing the trend in ATBF.

Similar content being viewed by others

References

Mirchandani, K., Klaphake, E.L., Gallaghar, T.M.: Strategies for obtaining optimum performance from cemented carbide rod and bar mill rolls. In: Proceedings, International Seminar ROLL TECH 2000, April 11–12, Jamshedpur, pp. 91–109 (1997)

Rackoff, W.H., Klaphake, E.L.: Rolls for the Metalworking Industries, pp. 281–306. ISS Publication

Acknowledgments

The authors are thankful to the management of TATA STEEL for giving permission to publish this paper. Thanks are due to the staff of Roll Shop of Wire and Rod Mill. Thanks are also due to the staff of Met. Lab. Scientific Services in conducting failure investigation of rolls.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Pandey, J.C., Raj, M. & Chakraborty, T.K. Failure of Tungsten Carbide Rolls from a Wire and Rod Mill . J Fail. Anal. and Preven. 7, 92–99 (2007). https://doi.org/10.1007/s11668-007-9021-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11668-007-9021-9