Abstract

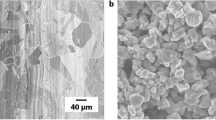

In order to explore the feasibility of cold spraying as method to prepare Cu-Cr composite, the deposition behavior was analyzed. The results show that particles parameters, such as morphology, size distribution and deformability, result in different deposition behavior. For Cu, since plastic deformation easily occurs, when a Cu particle impacts Cu substrate, both particle and substrate at the interface undergo extensive deformation, resulting in the greater bond probability. Although the velocity of Cr is higher than that of Cu, Cr particles have lower bond probability because of its hardness and fragility. Cr particles are embedded in the Cu particles. The properties of Cu-15%Cr meet industrial standard, superior to the composite prepared by explosive compaction. The results reveal cold spraying can be considered as a suitable technology for Cu-Cr composite.

Similar content being viewed by others

References

W. Li, R.L. Thomas, and R.K. Smith, Effects of Cr Content on the Interruption Ability of CuCr Contact Materials, IEEE Trans. Plasma Sci., 2001, 29(5), p 744-748

P.G. Slade, Advances in Material Development for High Power, Vacuum Interrupter Contacts, IEEE Trans. Compon. Packag. Manuf. Technol. A, 1994, 17(1), p 96-106

I. Lahiri and S. Bhargava, Compaction and Sintering Response of Mechanically Alloyed Cu-Cr Powder, Powder Technol., 2009, 189(3), p 433-438

C. Zhang, Y. Wang, Z. Yang, Y. Guo, and D. Bingjun, Microstructure and Properties of Vacuum Induction Melted CuCr25 Alloys, J. Alloy. Compd., 2004, 366(1-2), p 289-292

Z.M. Zhou, Y.P. Wang, J. Gao, and M. Kolbe, Microstructure of Rapidly Solidified Cu-25wt.%Cr Alloys, Mater. Sci. Eng. A, 2005, 398(1-2), p 318-322

X. Wang, J. Zhao, and J. He, Investigation on the Microstructure and Mechanical Properties of the Spray-Formed Cu-Cr Alloys, Mater. Sci. Eng. A, 2007, 460-461(7), p 69-76

K.T. Chiang, P.D. Krotz, and J.L. Yuen, Blanching Resistant Cu-Cr Coating by Vacuum Plasma Spray, Surf. Coat. Technol., 1995, 76-77(Part 1), p 14-19

A. Papyrin, Cold Spray Technology, Adv. Mater. Process., 2001, 159(9), p 49-51

G. Bae, Y. Xiong, S. Kumar, K. Kang, and C. Lee, General Aspects of Interface Bonding in Kinetic Sprayed Coatings, Acta Mater., 2008, 56(17), p 4858-4868

H. Assadi, F. Gartner, T. Stoltenhoff, and H. Kreye, Bonding Mechanism in Cold Gas Spraying, Acta Mater., 2003, 51(15), p 4379-4394

V. Luzin, K. Spencer, and M.X. Zhang, Residual Stress and Thermo-Mechanical Properties of Cold Spray Metal Coatings, Acta Mater., 2011, 59(3), p 1259-1270

S.B. Kang, H.K. Kang, and K. Euh, Processing and Microstructures of Tungsten/Copper Composites Produced by Plasma Spray and Cold Spray, Mater. Sci. Forum, 2005, 475-479(PRICM 5), p 475-479, 945

H.K. Kang and S.B. Kang, Tungsten/Copper Composite Deposits Produced by a Cold Spray, Scr. Mater., 2003, 49(12), p 1169-1174

S. Shin, S. Yoon, Y. Kim, and C. Lee, Effect of Particle Parameters on the Deposition Characteristics of a Hard/Soft-Particles Composite in Kinetic Spraying, Surf. Coat. Technol., 2006, 201(6), p 3457-3461

H.T. Wang, C.J. Li, G.J. Yang, and C.X. Li, Cold Spraying of Fe/Al Powder Mixture: Coating Characteristics and Influence of Heat Treatment on the Phase Structure, Appl. Surf. Sci., 2008, 255(5), p 2538-2544

T. Novoselova, P. Fox, R. Morgan and N. W. O, Experimental study of titanium/aluminium deposits produced by cold gas dynamic spray. Surf. Coat. Technol., 2006, 200(8), 2775-2783

D. Pantelis, K. Triantou, C. Sarafoglou, D. Christoulis, F. Borit, V. Guipont, and M. Jeandin, Microstructural Study of Copper and Copper/Alumina Composite Coatings Produced by Cold Spray Process, Adv. Mater. Res., 2010, 89-91(THERMEC 2009 Supplement), p 556-561

W.Y. Li, C.J. Li, H.T. Wang, C.X. Li, and H.S. Bang, Measurement and Numerical Simulation of Particle Velocity in Cold Spraying, J. Therm. Spray Technol., 2006, 15(4), p 559-562

G. Bae, S. Kumar, S. Yoon, K. Kang, H. Na, H. Kim, and C. Lee, Bonding Features and Associated Mechanisms in Kinetic Sprayed Titanium Coatings, Acta Mater., 2009, 57(19), p 5654-5666

S. Kumar, H. Na, V. Selvarajan, and C. Lee, Influence of Metal Powder Shape on Drag Coefficient in a Spray Jet, Curr. Appl. Phys., 2009, 9(3), p 678-682

S. Shin, Y. Xiong, Y. Ji, H.J. Kim, and C. Lee, The Influence of Process Parameters on Deposition Characteristics of a Soft/Hard Composite Coating in Kinetic Spray Process, Appl. Surf. Sci., 2008, 254(8), p 2269-2275

G. Bae, K. Kang, J. Kim, and C. Lee, Nanostructure Formation and Its Effects on the Mechanical Properties of Kinetic Sprayed Titanium Coating, Mater. Sci. Eng. A, 2010, 527(23), p 6313-6319

Acknowledgments

This work was financially supported by the National Natural Science Foundation of China (Nos. 50871019 and 50874009) and State Key Laboratory for Advanced Metals and Materials, University of Science and Technology Beijing.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wu, Xk., Zhou, Xl., Cui, H. et al. Deposition Behavior and Characteristics of Cold-Sprayed Cu-Cr Composite Deposits. J Therm Spray Tech 21, 792–799 (2012). https://doi.org/10.1007/s11666-012-9755-0

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-012-9755-0