Abstract

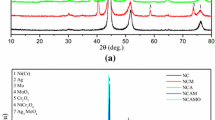

The effect of multiple stoichiometric strontium aluminates (Sr4Al14O25, SrAl12O19, and Sr4Al2O7) on the tribological properties of NiCr-Al2O3 composites was investigated between room temperature and 800 °C. The results indicated that the synergistic interaction of multiple stoichiometric strontium aluminates played an important role in the improvement in the friction and wear performance at elevated temperatures. Satisfactory tribological properties were observed for the synergistic lubricating film consisting of Sr4Al14O25, SrAl12O19, and oxides (NiO, Cr2O3, and NiCr2O4) on the worn surface above 600 °C, compared to those for the tribofilm containing Sr4Al14O25, SrAl12O19, Sr4Al2O7, SrCrO4, and oxides. Furthermore, the low friction coefficient and wear rate were attributed to the formation of Sr4Al14O25, Sr4Al2O7, SrCrO4, and oxides on the rubbing surface at 800 °C.

Similar content being viewed by others

References

H. Torres, M. Rodríguez Ripoll, and B. Prakash, Tribological Behaviour of Self-lubricating Materials at High Temperatures, Int. Mater. Rev., 2018, 63, p 309–340

S. Zhu, J. Cheng, Z. Qiao, and J. Yang, High Temperature Solid-Lubricating Materials: A Review, Tribol. Int., 2019, 133, p 206–223

M. Kotkowiak, A. Piasecki, and M. Kulka, The Influence of Solid Lubricant on Tribological Properties of Sintered Ni-20%CaF2 Composite Material, Ceram. Int., 2019, 45, p 17103–17113

S. Cao, J. Zhou, L. Wang, Y. Yu, and B. Xin, Microstructure, Mechanical and Tribological Property of Multi-components Synergistic Self-lubricating NiCoCrAl Matrix Composite, Tribol. Int., 2019, 131, p 508–519

T.R. Prabhu, M. Arivarasu, Y. Chodancar, N. Arivazhagan, G. Sumanth, and R.K. Mishra, Tribological Behaviour of Graphite-Reinforced FeNiCrCuMo High-Entropy Alloy Self-lubricating Composites for Aircraft Braking Energy Applications, Tribol. Lett., 2019, 67, p 78

G. Cui, H. Liu, S. Li, G. Gao, and Z. Kou, Design and High-Temperature Tribological Properties of CoCrW with Rare Earth Fluoride Composites, J. Mater. Res. Technol., 2020, 9, p 2402–2411

X.J. Yuan, X.H. Chen, B.L. Zha, and Z.H. Yu, Structural and Tribological Performance of Solid NiCr-WSe2-BaF2·CaF2-Y-hBN and NiCr-WSe2-BaF2·CaF2-Y Lubricant Coatings Produced by Atmospheric Plasma Spray, Tribol. Trans., 2017, 60, p 208–216

C.H. Ding, P.L. Li, G. Ran, Y.W. Tian, and J.N. Zhou, Tribological Property of Self-lubricating PM304 Composite, Wear, 2007, 262, p 575–581

F. Findik, Latest progress on tribological properties of industrial materials, Mater. Des., 2014, 57, p 218–244

N. Altinkok, I. Oezsert, and F. Findik, Dry Sliding Wear Behavior of Al2O3/SiC Particle Reinforced Aluminium Based MMCs Fabricated by Stir Casting Method, Acta Phys. Polonica, 2013, 124, p 11–19

H. Zhao, L. Luo, F. Guo, X. Zhao, and P. Xiao, High-Temperature Tribological Behavior of Mo and BaF2 Added Cr3C2-NiCr Matrix Composite, Ind. Lubric. Tribol., 2019, 72, p 136–145

A. Sabahi Namini, S.A.A. Dilawary, A. Motallebzadeh, and Asl M. Shahedi, Effect of TiB2 Addition on the Elevated Temperature Tribological Behavior of Spark Plasma Sintered Ti Matrix Composite, Compos. B Eng., 2019, 172, p 271–280

X. Li, J. Liang, T. Shi, D. Yang, X. Chen, C. Zhang et al., Tribological Behaviors of Vacuum Hot-Pressed Ceramic Composites with Enhanced Cyclic Oxidation and Corrosion Resistance, Ceram. Int., 2020, 46, p 12911–12920

X. Feng, J. Jia, Q. Gao, C. Lu, J. Yang, P. Shi et al., Regeneration Mechanisms of Silver Niobate in NiAl Composites with Respective Addition of AgNbO3 and Ag/Nb2O5 at Elevated Temperatures Sliding, Tribol. Int., 2021, 153, p 106623

X. Dai, M. Wen, J. Wang, X. Cui, X. Wang, and K. Zhang, The Tribological Performance at Elevated Temperatures of MoNbN-Ag Coatings, Appl. Surf. Sci., 2020, 509, p 145372

P. Ren, K. Zhang, X. He, S. Du, X. Yang, T. An et al., Toughness Enhancement and Tribochemistry of the Nb-Ag-N Films Actuated by Solute Ag, Acta Mater., 2017, 137, p 1–11

S. Zhu, H. Tan, J. Cheng, Y. Yu, Z. Qiao, and J. Yang, Nickel Aluminum Matrix Solid-Lubricating Composite Lubricated by Silver and Silver Vanadate Formed by Tribochemistry at Elevated Temperature, J. Tribol., 2019, 2019, p 141

S.M. Aouadi, D.P. Singh, D.S. Stone, K. Polychronopoulou, F. Nahif, C. Rebholz et al., Adaptive VN/Ag Nanocomposite Coatings with Lubricious Behavior from 25 to 1000 C, Acta Mater., 2010, 58, p 5326–5331

Y. Mu, M. Liu, Y. Wang, and E. Liu, PVD Multilayer VN-VN/Ag Composite Coating with Adaptive Lubricious Behavior from 25 to 700 °C, RSC Adv., 2016, 6, p 53043–53053

H. Ju, N. Ding, J. Xu, L. Yu, Y. Geng, and F. Ahmed, The Tribological Behavior of Niobium Nitride and Silver Composite Films at Elevated Testing Temperatures, Mater. Chem. Phys., 2019, 237, p 121840

X. Feng, C. Lu, J. Jia, J. Xue, Q. Wang, Y. Sun et al., High Temperature Tribological Behaviors and Wear Mechanisms of NiAl-NbC-Ag Composites Formed by In Situ Decomposition of AgNbO3, Tribol. Int., 2020, 141, p 105898

B. Li, Y. Gao, X. Hou, C. Li, H. Guo, Y. Kang et al., Microstructure, Mechanical and Tribological Properties of NiAl Matrix Composites with Addition of BaO/TiO2 Binary Oxides, Tribol. Int., 2020, 144, p 106108

F. Liu, L. Feng, H. Liu, and W. Zhao, High-Temperature Tribological Performance of Vacuum Hot-Pressed NiCr Matrix Composite Containing SrAl12O19, J. Mater. Eng. Perform., 2020, 29, p 470–479

F. Liu, Y. Zhou, X. Zhang, W. Cao, and J. Jia, Tribological Properties of NiCr-ZrO2(Y2O3)-SrSO4 Composites at Elevated Temperatures, Ceram. Int., 2016, 42, p 12981–12987

F. Liu, G.W. Yi, W.Z. Wang, Y. Shan, and J.H. Jia, The Influence of SrSO4 on the Tribological Properties of NiCr-Al2O3 Cermet at Elevated Temperatures, Ceram. Int., 2014, 40, p 2799–2807

F. Liu, G.W. Yi, W.Z. Wang, Y. Shan, and J.H. Jia, Tribological Properties of NiCr-Al2O3 Cermet-Based Composites with Addition of Multiple-Lubricants at Elevated Temperatures, Tribol. Int., 2013, 67, p 164–173

F. Liu and J.H. Jia, Tribological Properties and Wear Mechanisms of NiCr-Al2O3-SrSO4-Ag Self-Lubricating Composites at Elevated Temperatures, Tribol. Lett., 2013, 49, p 281–290

F. Liu, J. Ren, H. Liu, W. Zhao, X. Zhang, and W. Cao, Tribological Properties of In Situ-Fabricated NiCr-Al2O3 Composites with SrAl4O7 and SrO at Elevated Temperatures, J. Mater. Eng. Perform., 2020, 29, p 6670–6680

M.L. Capron and A. Douy, Strontium Dialuminate SrAl4O7: Synthesis and Stability, J. Am. Ceram. Soc., 2002, 85, p 3036–3040

R. Khanna and B. Basu, Sliding Wear Properties of Self-Mated Yttria-Stabilized Tetragonal Zirconia Ceramics in Cryogenic Environment, J. Am. Ceram. Soc., 2007, 90, p 2525–2534

L. Chen, S. Xue, X. Chen, A. Bahader, X. Deng, E. Zhao et al., The Site Occupation and Valence of Mn Ions in the Crystal Lattice of Sr4Al14O25 and Its Deep Red Emission for High Color-Rendering White Light-Emitting Diodes, Mater. Res. Bull., 2014, 60, p 604–611

Y. Xu, W. Peng, S. Wang, X. Xiang, and P. Lu, Synthesis of SrAl12O19 Via Citric Acid Precursor, Mater. Sci. Eng. B, 2005, 123, p 139–142

S.J. Kim, H.I. Won, N. Hayk, C.W. Won, D.Y. Jeon, and A.G. Kirakosyan, Preparation and Characterization of Sr4Al2O7:Eu3+, Eu2+ Phosphors, Mater. Sci. Eng. B, 2011, 176, p 1521–1525

M. Bukhtiyarova, A. Ivanova, E. Slavinskaya, P. Kuznetsov, L. Plyasova, O. Stonkus et al., Steam Reforming of Methane Over Ni-Substituted Sr Hexaaluminates, Catal. Sustain. Energy, 2012, 2012, p 11–21

Acknowledgments

This research was supported by the National Natural Science Foundation of China (Grant No. 51505378) and the Natural Science Basic Research Plan in Shaanxi Province of China (Program No. 2017JM5101).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Liu, F., Ren, J., Liu, H. et al. The Effect of Various Stoichiometric Strontium Aluminates on the High-Temperature Tribological Properties of NiCr-Al2O3 Composites. J. of Materi Eng and Perform 30, 2193–2203 (2021). https://doi.org/10.1007/s11665-021-05537-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-021-05537-2