Abstract

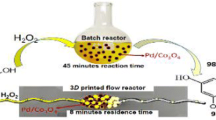

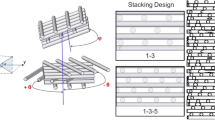

The benefits of 3D-printing technology in the manufacturing of laboratory equipment, in particular catalytic applications, have recently been brought to the limelight. In this paper, continuous-flow reaction devices consisting of syringe pumps and flow reactors were fabricated using a 3D-printing technique which aims at circumventing the high cost of procuring the convectional reactors for catalytic reactions. Mesoporous manganese metal oxide (MnMMO) and mesoporous cobalt metal oxide (CoMMO) catalysts were synthesized and fully characterized. The catalytic activity of the prepared nanocatalysts was evaluated in a continuous-flow operation using an in-house 3D-printed flow device for the reduction of hexacyanoferrate ion into a useful intermediate compound industrially. Different reaction parameters such as flow rates, temperature, and catalyst amount were investigated for the system’s optimization. The result showed an impressive output with an outstanding conversion of 94.1% hexacyanoferrate ion in 6-minute reaction time. Also, the excellent stability of five-run reusability on hexacyanoferrate ion was performed in a safe, faster, and well-controlled microenvironment.

Graphic Abstract

Similar content being viewed by others

References

M.R. Chapman, M.H.T. Kwan, G. King, K.E. Jolley, M. Hussain, S. Hussain, I.E. Salama, C. Gonza, L.A. Thompson, M.E. Bayana, A.D. Clayton, B.N. Nguyen, N.J. Turner, N. Kapur and A.J. Blacker, Simple and Versatile Laboratory Scale CSTR for Multiphasic Continuous-Flow Chemistry and Long Residence Times, Org. Process Res. Dev., 2017, 21(9), p 1294–1301.

J.M. Neumaier, A. Madani, T. Klein and T. Ziegler, Low-Budget 3D-Printed Equipment for Continuous Flow Reactions, Beilstein J. Org. Chem., 2019, 15(1), p 558–566.

K. Maresz, A. Ciemięga and J. Mrowiec-Białoń, Selective Reduction of Ketones and Aldehydes in Continuous-Flow Microreactor—Kinetic Studies, Catalysts, 2018, 8(5), p 221.

S.Z. Shirejini and A. Mohammadi, Halogen-Lithium Exchange Reaction Using an Integrated Glass Microfluidic Device: An Optimized Synthetic Approach, Org. Process Res. Dev., 2017, 21(3), p 292–303.

C. De Risi, O. Bortolini, A. Brandolese, G. Di Carmine, D. Ragno and A. Massi, Recent Advances in Continuous-Flow Organocatalysis for Process Intensification, React. Chem. Eng., 2020, 5, p 1017–1052.

X. Liu, B. Ünal and K.F. Jensen, Heterogeneous Catalysis with Continuous Flow Microreactors, Catal. Sci. Technol., 2012, 2(10), p 2134–2138.

R. Ricciardi, R. Munirathinam, J. Huskens and W. Verboom, Improved Catalytic Activity and Stability Using Mixed Sulfonic Acid- and Hydroxy-Bearing Polymer Brushes in Microreactors, ACS Appl. Mater. Interfaces, 2014, 6(12), p 9386–9392.

O.A. Alimi, N. Bingwa and R. Meijboom, Chemical Engineering Research and Design Homemade 3 -D Printed Flow Reactors for Heterogeneous Catalysis, Chem. Eng. Res. Des., 2019, 150, p 116–129.

A. Tanimu, S. Jaenicke and K. Alhooshani, Heterogeneous Catalysis in Continuous Flow Microreactors: A Review of Methods and Applications, Chem. Eng. J., 2017, 327, p 792–821.

M.R. Penny and S.T. Hilton, Design and Development of 3D Printed Catalytically-Active Stirrers for Chemical Synthesis, React. Chem. Eng., 2020, 5(5), p 853–858.

S. Rossi, A. Puglisi and M. Benaglia, Additive Manufacturing Technologies: 3D Printing in Organic Synthesis, ChemCatChem, 2018, 10(7), p 1–15.

D. Ko, K. Gyak and D. Kim, Emerging Microreaction Systems Based on 3D Printing Techniques and Separation Technologies, J. Flow Chem, 2017, 7(3–4), p 72–81.

C. Parra-cabrera, C. Achille, S. Kuhn and R. Ameloot, 3D Printing in Chemical Engineering and Catalytic Technology: Structured Catalysts, Mixers and Reactors, Chem. Soc. Rev., 2017, 47(1), p 209–230.

A.K. Au, W. Huynh, L.F. Horowitz and A. Folch, 3D-Printed Microfluidics, Angew. Chem. Int. Ed., 2016, 55(12), p 3862–3881.

P.J. Kitson, S. Glatzel, W. Chen, C. Lin, Y. Song and L. Cronin, 3D Printing of Versatile Reactionware for Chemical Synthesis, Nat. Protoc., 2016, 11(5), p 920–936.

S.K. Nirveek and A.F. Bhattacharjee, Arturo Urrios, The Upcoming 3D-Printing Revolution in Microfluidics, Lab Chip, 2016, 16(10), p 1720–1742.

A.J. Capel, S. Edmondson, S.D.R. Christie, R.D. Goodridge, R.J. Bibb and M. Thurstans, Design and Additive Manufacture for Flow Chemistry, R. Soc. Chem., 2013, 13, p 4583–4590.

L.P. Bressan, J. Robles-Najar, C.B. Adamo, R.F. Quero, B.M.C. Costa, D.P. de Jesus and J.A.F. da Silva, 3D-Printed Microfluidic Device for the Synthesis of Silver and Gold Nanoparticles, Microchem. J., 2019, 146, p 1083–1089.

M.S. Hossain and H. Taheri, In Situ Process Monitoring for Additive Manufacturing Through Acoustic Techniques, J. Mater. Eng. Perform., 2020, 29, p 6249–6262.

M.V. Bandulasena, G.T. Vladisavljević, O.G. Odunmbaku and B. Benyahia, Continuous Synthesis of PVP Stabilized Biocompatible Gold Nanoparticles with a Controlled Size Using a 3D Glass Capillary Microfluidic Device, Chem. Eng. Sci., 2017, 171, p 233–243.

L. Xu, J. Peng, M. Yan, D. Zhang and A.Q. Shen, Chemical Engineering and Processing: Process Intensification Droplet Synthesis of Silver Nanoparticles by a Micro Fluidic Device, Chem. Eng. Process. Process Intensif., 2016, 102, p 186–193.

R. Karnik, F. Gu, P. Basto, C. Cannizzaro, L. Dean, W. Kyei-manu, R. Langer and O.C. Farokhzad, Microfluidic Platform for Controlled Synthesis of Polymeric Nanoparticles, Nano Lett., 2008, 8(9), p 2906–2912.

L. Uson, M. Arruebo, V. Sebastian and J. Santamaria, Single Phase Microreactor for the Continuous, High-Temperature Synthesis of < 4 Nm Superparamagnetic Iron Oxide Nanoparticles, Chem. Eng. J., 2018, 340, p 66–72.

L.L. Lazarus, C.T. Riche, B.C. Marin, M. Gupta, N. Malmstadt and R.L. Brutchey, Two-Phase Microfluidic Droplet Flows of Ionic Liquids for the Synthesis of Gold and Silver Nanoparticles, Science, 2012, 4(6), p 3077–3083.

C. Rosso, S. Gisbertz, J.D. Williams, H.P.L. Gemoets, W. Debrouwer, B. Pieber and C.O. Kappe, An Oscillatory Plug Flow Photoreactor Facilitates Semi-Heterogeneous Dual Nickel/Carbon Nitride Photocatalytic C-N Couplings, React. Chem. Eng., 2020, 5(3), p 597–604.

H.P.L. Gemoets, Y. Su, M. Shang, V. Hessel, R. Luque and T. Noël, Liquid Phase Oxidation Chemistry in Continuous-Flow Microreactors, Chem. Soc. Rev., 2016, 45(1), p 83–117.

T. Ge, Z. Hua, X. He, Y. Zhu, W. Ren, L. Chen, L. Zhang, H. Chen, C. Lin, H. Yao and J. Shi, One-Pot Synthesis of Hierarchically Structured ZSM-5 Zeolites Using Single Micropore-Template, Chinese J. Catal., 2015, 36(6), p 866–873.

P. Hervés, M. Pérez-lorenzo, L.M. Liz-marzán, J. Dzubiella, Y. Lu, M. Ballauff, P. Herve, J. Dzubiella, Y. Lu and M. Ballauff, Chem Soc Rev Catalysis by Metallic Nanoparticles in Aqueous Solution: Model Reactions W, Chem. Soc. Rev., 2012, 41(17), p 5577–5587.

A.G. Assefa, A.A. Mesfin, M.L. Akele, A.K. Alemu, B.R. Gangapuram, V. Guttena and M. Alle, Microwave-Assisted Green Synthesis of Gold Nanoparticles Using Olibanum Gum (Boswellia Serrate) and its Catalytic Reduction of 4-Nitrophenol and Hexacyanoferrate (III) by Sodium Borohydride, J. Clust. Sci., 2017, 28(3), p 917–935.

J. Chen, F. Chen, Y. Wang, M. Wang, Q. Wu, X. Zhou and X. Ge, One-Step Synthesis of Poly (Ethyleneglycol Dimethacrylate)-Microspheres-Supported Nano-Au Catalyst in Methanol-Water Solution under γ-Ray Radiation, RSC Adv., 2016, 6(61), p 55878–55883.

X. Liu, Y. Shen, R. Yang, S. Zou, X. Ji, L. Shi, Y. Zhang, D. Liu, L. Xiao, X. Zheng, S. Li, J. Fan and G.D. Stucky, Inkjet Printing Assisted Synthesis of Multicomponent Mesoporous Metal Oxides for Ultrafast Catalyst Exploration, Nano Lett., 2012, 12(11), p 5733–5739.

Y. Du, Q. Meng, J. Wang, J. Yan, H. Fan, Y. Liu and H. Dai, Three-Dimensional Mesoporous Manganese Oxides and Cobalt Oxides: High-Efficiency Catalysts for the Removal of Toluene and Carbon Monoxide, Microporous Mesoporous Mater., 2012, 162, p 199–206.

S.K. Ghosh and H. Rahaman, Noble Metal-Manganese Oxide Hybrid Nanocatalysts, Noble Metal-Metal Oxide Hybrid Nanoparticles, 2019, 5, p 313–340.

P. Veerakumar, K. Salamalai, P. Thanasekaran and K.C. Lin, Simple Preparation of Porous Carbon-Supported Ruthenium: Propitious Catalytic Activity in the Reduction of Ferrocyanate(III) and a Cationic Dye, ACS Omega, 2018, 3(10), p 12609–12621.

S. Rossi, R. Porta, D. Brenna, A. Puglisi and M. Benaglia, Stereoselective Catalytic Synthesis of Active Pharmaceutical Ingredients in Homemade 3D-Printed Mesoreactors, Angew. Chemie, 2017, 129(15), p 4354–4358.

M. Hibben and S. Holmes, TINKERING with TINKERCAD A Beginner ’s Guide to Creating 3D Printer Designs With Presenters, https://www.tinkercad.com, 2017.

O.A. Alimi, C.A. Akinnawo, O.R. Onisuru and R. Meijboom, 3-D Printed Microreactor for Continuous Flow Oxidation of a Flavonoid, J. Flow Chem., 2020, 10, p 517–531.

O.A. Alimi, T.B. Ncongwane and R. Meijboom, Design and Fabrication of a Monolith Catalyst for Continuous Flow Epoxidation of Styrene in Polypropylene Printed Flow Reactor, Chem. Eng. Res. Des., 2020, 159, p 395–409.

G. 2016 C.S.M. Phytron, CATALOGUE STEPPER MOTORS Precision for Challenging Applications, 2016.

N. Masunga, G.S. Tito and R. Meijboom, A General Catalytic Evaluation of Mesoporous Metal Oxides for Liquid Phase Oxidation of Styrene, Appl. Catal. A Gen., 2018, 552, p 154–167.

A. Jha, T. Chandole, R. Pandya, H.S. Roh and C.V. Rode, Solvothermal Synthesis of Mesoporous Manganese Oxide with Enhanced Catalytic Activity for Veratryl Alcohol Oxidation, RSC Adv., 2014, 4(37), p 19450–19455.

K. Stangeland, D.Y. Kalai, Y. Ding and Z. Yu, Mesoporous Manganese-Cobalt Oxide Spinel Catalysts for CO2 Hydrogenation to Methanol, J CO2 Util, 2019, 32, p 146–154.

M. Qiu, S. Zhan, H. Yu, D. Zhu and S. Wang, Facile Preparation of Ordered Mesoporous MnCo2O4 for Low-Temperature Selective Catalytic Reduction of NO with NH3, Nanoscale, 2015, 7(6), p 2568–2577.

A.K. Ilunga, I.R. Legodi, S. Gumbi and R. Meijboom, Isothermic Adsorption of Morin onto the Reducible Mesoporous Manganese Oxide Materials Surface, Appl. Catal. B Environ., 2018, 224, p 928–939.

B.M. Mogudi, P. Ncube and R. Meijboom, Catalytic Activity of Mesoporous Cobalt Oxides with Controlled Porosity and Crystallite Sizes: Evaluation Using the Reduction of 4-Nitrophenol, Appl. Catal. B Environ., 2016, 198, p 74–82.

S. Carregal-romero, P. Jorge, P. Herv, L.M. Liz-marz and P. Mulvaney, Colloidal Gold-Catalyzed Reduction of Ferrocyanate ( III ) by Borohydride Ions: A Model System for Redox Catalysis, Science, 2010, 26(18), p 1271–1277.

I. Sarhid, I. Lampre, D. Dragoe, P. Beaunier, B. Palpant and H. Remita, Hexacyano Ferrate (III) Reduction by Electron Transfer Induced by Plasmonic Catalysis on Gold Nanoparticles, Materials (Basel)., 2019, 12(18), p 3012.

Q. Xia, D. Su, X. Yang, F. Chai, C. Wang and J. Jiang, One Pot Synthesis of Gold Hollow Nanospheres with Efficient and Reusable Catalysis, RSC Adv., 2015, 5(72), p 58522–58527.

R. Kanwar, R. Bhar and S.K. Mehta, Designed Meso-macroporous Silica Framework Impregnated with Copper Oxide Nanoparticles for Enhanced Catalytic Performance, ChemCatChem, 2018, 10(9), p 2087–2095.

Y. Liu and X. Jiang, Why Microfluidics? Merits and Trends in Chemical Synthesis, Lab Chip, 2017, 17(23), p 3960–3978.

G. Liu, X. Ma, X. Sun, Y. Jia and T. Wang, Controllable Synthesis of Silver Nanoparticles Using Three-Phase Flow Pulsating Mixing Microfluidic Chip, Adv. Mater. Sci. Eng., 2018, 20, p 18.

I.M. Mándity, S.B. Ötvös and F. Fülöp, Strategic Application of Residence-Time Control in Continuous-Flow Reactors, ChemistryOpen, 2015, 4(3), p 212–223.

X. Pu and Y. Su, Heterogeneous Catalysis in Microreactors with Nanofluids for Fine Chemicals Syntheses: Benzylation of Toluene with Benzyl Chloride over Silica-Immobilized FeCl3 Catalyst, Chem. Eng. Sci., 2018, 184, p 200–208.

C.P. Haas, T. Müllner, R. Kohns, D. Enke and U. Tallarek, High-Performance Monoliths in Heterogeneous Catalysis with Single-Phase Liquid Flow, React. Chem. Eng., 2017, 2(4), p 498–511.

G. Lente, Facts and Alternative Facts in Chemical Kinetics: Remarks about the Kinetic Use of Activities, Termolecular Processes, and Linearization Techniques, Curr. Opin. Chem. Eng., 2018, 21, p 76–83.

S.R. Thawarkar, B. Thombare, B.S. Munde and N.D. Khupse, Kinetic Investigation for the Catalytic Reduction of Nitrophenol Using Ionic Liquid Stabilized Gold Nanoparticles, RSC Adv., 2018, 8(67), p 38384–38390.

Z. Mohammadi and M.H. Entezari, Sono-Synthesis Approach in Uniform Loading of Ultrafine Ag Nanoparticles on Reduced Graphene Oxide Nanosheets: An Efficient Catalyst for the Reduction of 4-Nitrophenol, Ultrason. Sonochem., 2018, 44, p 1–13.

C. Xiao, Q. Wu, A. Chang, Y. Peng, W. Xu and W. Wu, Responsive Au@ Polymer Hybrid Microgels for the Simultaneous Modulation and Monitoring of Au-Catalyzed Chemical Reaction, J. Mater. Chem. A, 2014, 2(25), p 9514–9523.

K. Hareesh, R.P. Joshi, D.V. Sunitha, V.N. Bhoraskar and S.D. Dhole, Anchoring of Ag-Au Alloy Nanoparticles on Reduced Graphene Oxide Sheets for the Reduction of 4-Nitrophenol, Appl. Surf. Sci., 2016, 389, p 1050–1055.

W. Wang, Z. Han, X. Wang, C. Zhao and H. Yu, Polyanionic Clusters [M (P4Mo6) 2](M = Ni, Cd) as Effective Molecular Catalysts for the Electron-Transfer Reaction of Ferricyanide to Ferrocyanide, Inorg. Chem., 2016, 55(13), p 6435–6442.

U. Nithiyanantham, S.R. Ede, S. Anantharaj and S. Kundu, Self-Assembled NiWO4 Nanoparticles into Chain-like Aggregates on DNA Scaffold with Pronounced Catalytic and Supercapacitor Activities, Cryst. Growth Des., 2015, 15(2), p 673–686.

A.M. Kalekar, K.K.K. Sharma, A. Lehoux, F. Audonnet, H. Remita, A. Saha and G.K. Sharma, Investigation into the Catalytic Activity of Porous Platinum Nanostructures, Langmuir, 2013, 29(36), p 11431–11439.

K. Gong, Y. Liu and Z. Han, Manganese-Phosphomolybdate Molecular Catalysts for the Electron Transfer Reaction of Ferricyanide to Ferrocyanide, RSC Adv., 2015, 5(58), p 47004–47009.

Acknowledgments

We acknowledge the South African National Research Foundation {grant specific unique reference number (UID) 111710} for their support financially. We appreciate the University of Johannesburg for its funding as well as the availability of TEM in the spectra laboratory for analysis. We also thank Mr D. Harris and Dr. R. Meyer of Shimadzu South Africa (Pty) Ltd. for their instruments.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors have no conflict of interest to declare.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

This invited article is part of a special topical focus in the Journal of Materials Engineering and Performance on Additive Manufacturing. The issue was organized by Dr. William Frazier, Pilgrim Consulting, LLC; Mr. Rick Russell, NASA; Dr. Yan Lu, NIST; Dr. Brandon D. Ribic, America Makes; and Caroline Vail, NSWC Carderock.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Onisuru, O.R., Alimi, O.A., Potgieter, K. et al. Continuous-Flow Catalytic Degradation of Hexacyanoferrate Ion through Electron Transfer Induction in a 3D-Printed Flow Reactor. J. of Materi Eng and Perform 30, 4891–4901 (2021). https://doi.org/10.1007/s11665-021-05527-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-021-05527-4