Abstract

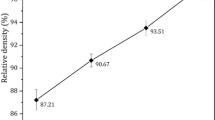

Polycrystalline cubic boron nitride (PcBN) reinforced by different morphologic titanium diboride (TiB2) was in situ synthesized in the temperature range of 1100-1600 °C under an ultra-high pressure of 5.5 GPa in cBN-Ti-Al system. The composition and microstructure of PcBN composites were investigated by x-ray diffractometry, scanning electron microscopy and energy-dispersive spectroscopy. The mechanism and influencing factors of TiB2 microstructure formation with different morphologies were analyzed. The mechanical properties of PcBN were also tested and analyzed. The results showed that the microstructure of TiB2 evolves from whisker to plate and rod to granular as the temperature increases. Under the combined effects of phase composition, relative density and TiB2 morphology, the microhardness of PcBN increased continuously, while the flexural strength first increased and then decreased. The high flexural strength was obtained at 1300 and 1400 °C, which were 840.39 and 823.32 MPa, respectively.

Similar content being viewed by others

References

G.Z. Wang, 立方氮化硼 (cBN) 特性综述 (Summarization About the Peculiarities of cBN), Superhard Mater. Eng., 2005, 17(5), p 41–45 ((in Chinese))

S. Ono, K. Mibe, N. Hirao, and Y. Ohishi, In Situ Raman Spectroscopy of Cubic Boron Nitride to 90 GPa and 800 K, J. Phys. Chem. Solids, 2005, 76, p 120–124 ((in English))

S. Yin, H.Y. Lai, and X.C. Cheng, 立方氮化硼烧结体的显微结构和烧结机理 (Microstructure and Sintering Mechanism of Sintered Cubic Boron Nitride Materials), J. Chin. Ceram. Soc., 1984, 12(4), p 450–455 ((in Chinese))

L. Chen, J.E. Stahl, W. Zhao, and J.M. Zhou, Assessment on Abrasiveness of High Chromium Cast Iron Material on the Wear Performance of PCBN Cutting Tools in Dry Machining, J. Mater. Process. Technol., 2018, 255, p 110–120 ((in English))

X.L. Liu, S.Y. Li, T. Chen, and D.Y. Wang, Research on the Surface Characteristics of Hardened Steel with Variable Chamfer Edge PCBN Insert by High-Speed Hard Turning, Int. J. Precis. Eng. Manuf., 2018, 19(2), p 157–165 ((in English))

M. Ociepa, M. Jenek, and E. Feldshtein, On the Wear Comparative Analysis of Cutting Tools Made of Composite Materials Based on Polycrystalline Cubic Boron Nitride When Finish Turning of AISI, D2 (EN X153CrMoV12) Steel, J. Superhard Mater., 2018, 40(6), p 396–401 ((in English))

D.S. King, W.G. Fahrenholtz, and G.E. Hilmas, Silicon Carbide-Titanium Diboride Ceramic Composites, J. Eur. Ceram. Soc., 2013, 33(15–16), p 2943–2951 ((in English))

Q. Wen, Y.Q. Tan, Z.H. Zhong, H.B. Zhang, and X.S. Zhou, High Toughness and Electrical Discharge Machinable B4C-TiB2-SiC Composites Fabricated at Low Sintering Temperature, Mater. Sci. Eng. A, 2017, 701, p 338–343 ((in English))

S.G. Huang, K. Vanmeensel, O. Van der Biest, and J. Vleugels, In Situ Synthesis and Densification of Submicrometer-Grained B4C-TiB2 Composites by Pulsed Electric Current Sintering, J. Eur. Ceram. Soc., 2011, 31(4), p 637–644 ((in English))

A.A. Abdel-Hamid, S. Hamar-Thibault, and R. Hamar, Crystal Morphology of the Compound TiB2, J. Cryst. Growth, 1985, 71(3), p 744–750 ((in English))

J.S. Li, F. Zhao, S. Li, M.Y. Wang, and X.J. Wu, 燃烧剂对二硼化钛晶体形态的影响 (Effect of Combustion Agent on the Crystal Morphology of TiB2), Rare Met. Mater. Eng., 2015, 44(S1), p 332–335 ((in Chinese))

H. Zhang, W.L. Gao, Y.X. Jin, and S.Y. Zeng, Evolution of Solid–Liquid Interface Morphology of Primary TiB2 in Non-equilibrium Solidified Ti-Al-B Alloys, Trans. Nonferrous Met. Soc. China, 2002, 12(3), p 437–440 ((in English))

W.L. Gao, H. Zhang, E.L. Zang, and S.Y. Zeng, TiAl-B合金中初生TiB2晶体的表面形貌和形成机制 (Surface Morphology and Growth Mechanism of Primary TiB2 in TiAl-B Alloys), Mater. Sci. Technol., 2002, 10(4), p 387–390 ((in Chinese))

L. Xu, C.Z. Huang, H.L. Liu, B. Zou, H.T. Zhu, G.L. Zhao, and J. Wang, In Situ Synthesis of ZrB2–ZrCX Ceramic Tool Materials Toughened by Elongated ZrB2 Grains, Mater. Des., 2013, 49, p 226–233 ((in English))

G.L. Zhao, C.Z. Huang, H.L. Liu, B. Zou, H.T. Zhu, and J. Wang, Microstructure and Mechanical Properties of TiB2–SiC Ceramic Composites by Reactive Hot Pressing, Int. J. Refract. Met. Hard Mater., 2014, 42, p 36–41 ((in English))

J. Qian, D. Mukhopadhyay, K.D. Nguyen, K.B. Bertagnolli, and Y. Ma, Sintering of Polycrystalline Boron Nitride Composites for In Situ Synchrotron High Pressure Research, Int. J. Refract. Met. Hard Mater., 2015, 49, p 288–291 ((in English))

R. Lv, J. Liu, Y.J. Li, S.C. Li, Z.L. Kou, and D.W. He, High Pressure Sintering of Cubic Boron Nitride Compacts with Al and AlN, Diamond Relat. Mater., 2008, 17(12), p 2062–2066 ((in English))

E. Benko, P. Klimczyk, J. Morgiel, A. Włochowicz, and T.L. Barr, Electron Microscopy Investigations of the cBN-Ti Compound Composites, Mater. Chem. Phys., 2003, 81(2–3), p 336–340 ((in English))

W.L. Yu, J.L. Wang, Y. Wu, Z.G. Zou, Q.F. Yu, and P.C. Mo, In Situ Synthesis of Polycrystalline Cubic Boron Nitride with High Mechanical Properties Using Rod-Shaped TiB2 Crystals as the Binder, Adv. Appl. Ceram., 2017, 116(8), p 419–427 ((in English))

M.E. Hyman, C. Mccullough, C.G. Levi, and R. Mehrabian, Evolution of Boride Morphologies in TiAl-B Alloys, Metall. Trans. A, 1991, 22(7), p 1647–1662 ((in English))

H. Zhang, W.L. Gao, E.L. Zhang, and S.Y. Zeng, TiAl-B合金片状TiB2晶体表面结构及其生长机理 (Surface Structure and Growth Mechanism of TiB2 Plate in TiAl-B Alloys), Acta Mater. Compos Sin., 2002, 19(2), p 45–48 ((in Chinese))

W.L. Gao, H. Zhang, E.L. Zhang, and S.Y. Zeng, TiAl-B合金中TiB2微观形态的主要存在方式 (Existing Way of the Morphology of TiB2 in TiAl-B Alloy), Foundry Technol., 2003, 24(3), p 176–178 ((in Chinese))

Y.J. Liu, D.W. He, P. Wang, X.Z. Yan, C. Xu, F.M. Liu, J. Liu, and Q.W. Hu, Microstructural and Mechanical Properties of cBN-Si Composites Prepared from the High Pressure Infiltration Method, Int. J. Refract. Met. Hard Mater., 2003, 61, p 1–5 ((in English))

Y.L. Chen, Z.Y. Li, J. Tang, C.W. Zeng, W. Gao, X. Yan, and M. Yan, Microstructure, Densification, Microhardness and Antioxidant Properties of Ti2AlN/TiN FGM Fabricated by Hot-Pressing, J. Wuhan Univ. Technol. Mater. Sci. Ed., 2014, 29(6), p 1173–1177 ((in English))

B.Q. Chen, H.P. Xiong, S.Q. Guo, B.B. Sun, B. Chen, and S.Y. Tang, Microstructure and Mechanical Properties of Dissimilar Welded Ti3Al/Ni-Based Superalloy Joint Using a Ni-Cu Filler Alloy, Metall. Mater. Trans. A, 2015, 46(2), p 756–761 ((in English))

C.P. Zhang, X.W. Gao, H.Q. Ru, W.K. Sun, J.H. Zhu, and H. Zong, 成形压力对SiC/TiB2复合材料组织与性能的影响 (Effect of Forming Pressure on Microstructure and Mechanical Properties of SiC/TiB2 Composites), J. Inorg. Mater., 2017, 32(5), p 502–508 ((in Chinese))

X.Z. Rong, T. Tsurumi, O. Fukunaga, and T. Yano, High-Pressure Sintering of cBN-TiN-Al Composite for Cutting Tool Application, Diamond Relat. Mater., 2002, 11(2), p 280–286 ((in English))

Y. Li, Z.L. Kou, H.K. Wang, K.X. Wang, H.C. Tang, Y.F. Wang, S.Z. Liu, X.T. Ren, C.M. Meng, and Z.G. Wang, High Pressure Sintering Behavior and Mechanical Properties of cBN–Ti3Al and cBN–Ti3Al-Al Composite Materials, High Pressure Res., 2012, 32(4), p 524–531 ((in English))

Y.G. Yuan, X.Z. Cheng, R. Chang, T.H. Li, J.B. Zang, Y.H. Wang, Y.Q. Yu, J. Lu, and X.P. Xu, Reactive Sintering cBN-Ti-Al Composites by Spark Plasma Sintering, Diamond Relat. Mater., 2016, 69, p 138–143 ((in English))

L.Y. Yang, Z.M. Yue, J.H. Gong, X.D. Zhao, and X.H. Chu, Compositions, Mechanical Properties and Microstructures of cBN-Based Composites Sintered with Al or TiC, Adv. Appl. Ceram., 2017, 116(5), p 254–259 ((in English))

J. Li, Y. Ma, L.X. Liang, H.L. Wang, and R. Zhang, 放电等离子烧结聚晶立方氮化硼刀具的性能 (Properties of Polycrystalline Cubic Boron Nitride Prepared by Spark Plasma Sintering), Mater. Mech. Eng., 2019, 43(1), p 8–12 ((in Chinese))

P.M. Mo, C. Chen, J.R. Chen, G. Jia, D.L. Xie, L.Y. Xiao, X.Y. Pan, and F. Ling, Effect of Sintering Temperature on Synthesis of PCBN in cBN-Ti-Al-W System, Diamond Relat. Mater., 2020, https://doi.org/10.1016/j.diamond.2020.107714

Acknowledgments

This study was financially supported by the Innovation-driven Development Special Fund Project of Guangxi Province, China (AA17204098) and project supported by The Open Research Project of Key Laboratory of Superhard Materials of Guangxi Province, China (2017-K-01).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zhong, S., Chen, C., Li, Z. et al. In Situ Synthesis of Polycrystalline Cubic Boron Nitride Reinforced by Different Morphologic TiB2. J. of Materi Eng and Perform 29, 3784–3791 (2020). https://doi.org/10.1007/s11665-020-04896-6

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-020-04896-6