Abstract

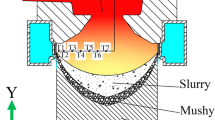

Herein, the tensile deformation behavior of pure copper castings with as-cast surfaces was investigated. It was found that small and sufficiently large uniform elongation types corresponded, respectively, to the presence or absence of a Cu-Cu2O eutectic phase in the microstructure. Fissure defects were observed near the as-cast surfaces when the eutectic phase was present, probably leading to stress concentration. On the other hand, surface pinholes were observed when the eutectic phase was absent, and these were not prevented by directional solidification. Although the as-cast specimens (non-directionally solidified) exhibited a slightly reduced uniform elongation compared to the machined specimens in the absence of the eutectic phase, the directionally solidified as-cast samples exhibited a uniform elongation that was similar to that of the machined specimens. In addition, micropore arrays were formed along the grain boundaries inside the castings when the eutectic phase was absent, whereas almost no micropores were observed inside the directionally solidified as-cast specimens because the solidification process involved a faster cooling rate and/or higher temperature gradient. These results do not only suggest the existence of surface pinholes but also indicate that microporosity can reduce the cross-sectional area of the specimens, thus, affecting their uniform elongation.

Similar content being viewed by others

References

I. Goto, K. Kurosawa, K. Ohguchi, S. Aso, H. Suzuki, H. Hayashi, and J. Shionoya, Factors Influencing Deformation Behavior of Pure Copper Castings for Electrical Parts, J. Jpn. Inst. Met. Mater., 2015, 79(10), p 511–517 (in Japanese)

I. Goto, S. Aso, K. Ohguchi, H. Oguri, K. Kurosawa, H. Suzuki, H. Hayashi, and J. Shionoya, Factors Influencing Deformation Behavior and Electrical Conductivity of Pure Copper Castings Fabricated by Industrial Process, J. Jpn. Inst. Met. Mater., 2017, 81(3), p 133–142 (in Japanese)

I. Goto, S. Aso, K. Ohguchi, K. Kurosawa, H. Suzuki, H. Hayashi, and J. Shionoya, Effect of Solidification Conditions on Deformation Behavior of Pure Copper Castings for Electrical Parts, 6th Korea-Japan Conference for Young Foundry Engineers, Korea Foundry Society, Seoul, Aug 25–27, 2016, p 124–127

I. Goto, S. Aso, K. Ohguchi, K. Kurosawa, H. Suzuki, H. Hayashi, and J. Shionoya, Effect of Solidification Conditions on the Deformation Behavior of Pure Copper Castings, Mater. Trans., 2019, 60(1), p 2–9

I. Goto, S. Aso, K. Ohguchi, K. Kurosawa, H. Suzuki, H. Hayashi, and J. Shionoya, Effect of Solidification Conditions on the Deformation Behavior of Pure Copper Castings, J. Jpn. Inst. Met. Mater., 2018, 82(11), p 423–430 (in Japanese)

M. Goto, Production of Pure Copper Castings, Such as Tuyere and Lancenozzle, Used in the Iron and Steel Industry, Tetsu-to-Hagané, 1986, 72(10), p 1481–1487 (in Japanese)

H. Ueno, Establishment of Melting/Casting Techniques for Copper Casting and Development of Cooling Members for Blast Furnaces, J. JFS, 2001, 73(7), p 469–474 (in Japanese)

Dogokin-imono-no-seisangijutsu-kaiteiban-henshuiinkai, Dogokin-imono-no-seisangijutsu (Materials Process Technology Center, 2014), p 87–93, 159, 264 (in Japanese)

Classification Standard of Copper and Copper Alloy Recycle Materials, JIS H 2109 (Japanese Industrial Standards Committee, 2006), p 1–2, 5 (in Japanese)

Metallic Materials—Tensile Testing—Method of Test at Room Temperature, JIS Z 2241 (Japanese Industrial Standards Committee, 2011), p 35, 39 (in Japanese)

G. Petzow, Metallographisches Keramographisches Plastographisches Ätzen (Nikkan Kogyo Shimbun, 1997), p 114 (in Japanese)

The Japan Society of Mechanical Engineers, JSME Data Book: Heat Transfer (Maruzen, 1986), p 314 (in Japanese)

I. Goto and S. Aso, Effects of As Cast Holes on Cooling Patterns in Directional Solidification of Plate Castings, Mater. Trans., 2017, 58(3), p 471–478

J.P. Neumann, T. Zhong, and Y.A. Chang, The Cu-O (Copper-Oxygen) System, Bull. Alloy Phase Diagr., 1984, 5(2), p 136–140

T.B. Massalski, J.L. Murray, L.H. Bennett, and H. Baker, Binary Alloy Phase Diagrams, Volume 1, American Society for Metals, Materials Park, 1986, p 944

I. Imafuku, A Study on the Estimation of the Generated Shrinkage Cavity in Steel Casting, Trans. Jpn. Soc. Mech. Eng. C, 1982, 48(436), p 1968–1976 (in Japanese)

Copper and Copper Alloy Castings, JIS H 5120 (Japanese Industrial Standards Committee, 2016), p 2, 9 (in Japanese)

Japan Foundry Engineering Society, Chuzokekkan-to-sono-taisaku (Japan Foundry Engineering Society, 2007), p 48, 65, 212 (in Japanese)

Japan Foundry Engineering Society, Casting Defects and Countermeasures (Japan Foundry Engineering Society, 2016), p 48, 65, 212

H. Ueno and N. Ukai, The Behavior of Oxygen and Hydrogen During Manufacturing Process and the Effects of Gases on the Soundness of Pure Copper Castings, J. Jpn. Foundarymen’s Soc., 1974, 46(1), p 57–63 (in Japanese)

E. Niyama, Chuzo-dennetsu-kogaku (Agne Gijutsu Center, 2001), p 97–98 (in Japanese)

S.K. Hyun, K. Murakami, and H. Nakajima, Mechanical Properties of Lotus-type Porous Copper, J. JFS, 2002, 74(12), p 817–821 (in Japanese)

E. Koya and M. Nakagawa, Effect of Defects on Mechanical Properties of JIS ADC12 Alloy Die Casting and its Trial for Prediction of Strength by Casting CAE, J. JFS, 2017, 89(12), p 782–787 (in Japanese)

K. Shigematsu, Effect of Drawing Speed on the Deep Drawability of Copper Sheet, Bull. Tsuyama Natl. College Technol., 1971, 3(1), p 13–16 (in Japanese)

Acknowledgments

This study was supported in part by the Japan Institute of Copper. The authors would like to thank Enago (www.enago.jp) for the English language review.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Goto, I., Aso, S., Ohguchi, Ki. et al. Deformation Behavior of Pure Copper Castings with As-Cast Surfaces for Electrical Parts. J. of Materi Eng and Perform 28, 3835–3843 (2019). https://doi.org/10.1007/s11665-019-3865-5

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-019-3865-5