Abstract

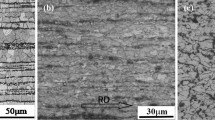

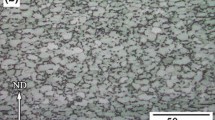

Grain structure and mechanical properties of 6063 Al alloy subjected to one, two and three passes via combined rolling–ECAP at room temperature were investigated. The yield strength (196 MPa) and tensile strength (242 MPa) after three passes increased by 3.7 times and three times, respectively, relative to the initial annealed alloy (YS: 53 MPa, UTS: 82 MPa). Heat treatment comprising homogenizing annealing (600 °C, 15 min), water quenching from 520 °C and reheating to 100 °C before each pass led to ultrafine grains (600-800 nm) and high yield strength (245 MPa) and tensile strength (277 MPa). The three-pass combined rolling–ECAP process in conjunction with a suitable heat treatment is an effective way to form UFG structure and improved mechanical properties in 6063 Al alloy.

Similar content being viewed by others

References

Y. Estrin and A. Vinogradov, Extreme Grain Refinement by Severe Plastic Deformation: A Wealth of Challenging Science, Acta Mater., 2013, 61(3), p 782–817

T. Sakai, A. Belyakov, R. Kaibyshev, H. Miura, and J.J. Jonas, Dynamic and Post-Dynamic Recrystallization Under Hot, Cold and Severe Plastic Deformation Conditions, Prog. Mater. Sci., 2014, 60, p 130–207

T.G. Langdon, Twenty-Five Years of Ultrafine-Grained Materials: Achieving Exceptional Properties Through Grain Refinement, Acta Mater., 2013, 61(19), p 7035–7059

R.Z. Valiev, Superior Strength in Ultrafine-Grained Materials Produced by SPD Processing, Mater. Trans., 2014, 55(1), p 13–18

I. Sabirov, M.Y. Murashkin, and R.Z. Valiev, Nanostructured Aluminium Alloys Produced by Severe Plastic Deformation: New Horizons in Development, Mater. Sci. Eng. A, 2013, 560, p 1–24

R.Z. Valiev, Y. Estrin, Z. Horita, T.G. Langdon, M.J. Zehetbauer, and Y.T. Zhu, Producing Bulk Ultrafine-Grained Materials by Severe Plastic Deformation: Ten Years Later, JOM, 2016, 68(4), p 1216–1226

T.G. Langdon, The Characteristics of Grain Refinement in Materials Processed by Severe Plastic Deformation, Rev. Adv. Mater. Sci., 2006, 13, p 6–14

L.S. Toth and C. Gu, Ultrafine-Grain Metals by Severe Plastic Deformation, Mater. Charact., 2014, 92, p 1–14

R.Z. Valiev, R.K. Islamgaliev, and I.V. Alexandrov, Bulk Nanostructured Materials from Severe Plastic Deformation, Prog. Mater Sci., 2000, 45(2), p 103–189

M. Jahedi, M. Knezevic, and M.H. Paydar, High-Pressure Double Torsion as a Severe Plastic Deformation Process: Experimental Procedure and Finite Element Modeling, J. Mater. Eng. Perform., 2015, 24(4), p 1471–1482

J. Straska, M. Janecek, J. Gubicza, T. Krajnak, E.Y. Yoon, and H.S. Kim, Evolution of Microstructure and Hardness in AZ31 Alloy Processed by High Pressure Torsion, Mater. Sci. Eng. A, 2015, 625, p 98–106

A. Alhamidi and Z. Horita, Grain Refinement and High Strain Rate Superplasticity in Alumunium 2024 Alloy Processed by High-Pressure Torsion, Mater. Sci. Eng. A, 2015, 622, p 139–145

R.Z. Valiev and T.G. Langdon, Principles of Equal-Channel Angular Pressing as a Processing Tool for Grain Refinement, Prog. Mater. Sci., 2006, 51, p 881–981

M.H. Shaeri, M.T. Salehi, S.H. Seyyedein, M.R. Abutalebi, and J.K. Park, Microstructure and Mechanical Properties of Al-7075 Alloy Processed by Equal Channel Angular Pressing Combined with Aging Treatment, Mater. Des., 2014, 57, p 250–257

X. Zhang, X. Liu, J. Wang, and Y. Cheng, Effect of Route on Tensile Anisotropy in Equal Channel Angular Pressing, Mater. Sci. Eng. A, 2016, 676, p 65–72

W. Wei, S.L. Wang, K.X. Wei, I.V. Alexandrov, Q.B. Du, and J. Hu, Microstructure and Tensile Properties of Cu-Al Alloys Processed by ECAP and Rolling at Cryogenic Temperature, J. Alloys Compd., 2016, 678, p 506–510

M. Vaseghi, H.S. Kim, A.K. Taheri, and A. Momeni, Inhomogeneity Through Warm Equal Channel Angular Pressing, J. Mater. Eng. Perform., 2013, 22(6), p 1666–1671

A. Jaeger and V. Gaertnerova, Equal Channel Angular Pressing of Magnesium at Room Temperature: The Effect of Processing Route on Microstructure and Texture, Philos. Mag. Lett., 2012, 92(8), p 384–390

X. Zhao, N. Chen, and N. Zhao, Numerical Simulation of Equal Channel Angular Pressing for Multi-Pass in Different Routes, Appl. Mech. Mater., 2012, 268–270, p 373–377

M. Gzyl, A. Rosochowski, E. Yakushina, P. Wood, and L. Olejnik, Route Effects in I-ECAP of AZ31B Magnesium Alloy, Key Eng. Mater., 2013, 554–557, p 876–884

G.I. Raab, G.V. Kulyasov, V.A. Polozovsky, R.Z. Valiev, Уcтpoйcтвo для oбpaбoтки мeтaллoв дaвлeниeм (A Device for Processing of Metals by Pressure), RU Patent 2,181,314 (2002). (in Russian)

A.B. Naizabekov, S.N. Lezhnev, and I.E. Volokitina, Change in Copper Microstructure and Mechanical Properties with Deformation in an Equal Channel Stepped Die, Met. Sci. Heat Treat., 2015, 57(5–6), p 254–260

D. Green, The continuous extrusion forming of wire sections, TRG Report 2364 (S), 1972.

R.G. Chembarisova and I.V. Aleksandrov, Simulation of the Elastoplastic Behavior of Grade-4 Ti in the ECAP-C Process, Met. Sci. Heat Treat., 2016, 58(3–4), p 236–244

D.V. Gunderov, A.V. Polyakov, I.P. Semenova, G.I. Raab, A.A. Churakova, E.I. Gimaltdinova et al., Evolution of Microstructure, Macrotexture and Mechanical Properties of Commercially Pure Ti During ECAP-Conform Processing and Drawing, Mater. Sci. Eng. A, 2013, 562, p 128–136

G.I. Raab, E.I. Fakhretdinova, R.Z. Valiev, L.P. Trifonenkov, and V.F. Frolov, Computer Study of the Effect of Tooling Geometry on Deformation Parameters in the Plastic Shaping of Aluminum Wire Rod by Multi-ECAP-Conform, Metallurgist, 2016, 59(11–12), p 1007–1014

C. Xu, S. Schroeder, P.B. Berbon, and T.G. Langdon, Principles of ECAP-Conform as a Continuous Process for Achieving Grain Refinement: Application to an Aluminum Alloy, Acta Mater., 2010, 58(4), p 1379–1386

M. Duchek, T. Kubina, J. Hodek, and J. Dlouhy, Development of the Production of Ultrafine-Grained Titanium with the Conform Equipment, Mater. Tehnol., 2013, 47(4), p 515–518

J. Hodek, T. Kubina, J. Dlouhy, FEM Model and Experimental Production of Titanium Rods Using Conform Machine, in 22nd International Conference on Metallurgy And Materials (METAL 2013), pp. 347–351

I.P. Semenova, A.V. Polyakov, G.I. Raab, T.C. Lowe, and R.Z. Valiev, Enhanced Fatigue Properties of Ultrafine-Grained Ti Rods Processed by ECAP-Conform, J. Mater. Sci., 2012, 47(22), p 7777–7781

A. Naizabekov, S. Lezhnev, Mathematical modeling of equal-channel angled drawing in step tool, in 21st International Conference on Metallurgy and Materials (METAL 2012), pp. 453–460

A. Volokitin, A. Naizabekov, S. Lezhnev, Research of a new method of deformation—”pressing–drawing” on mechanical properties of steel wire, in 22nd International Conference on Metallurgy And Materials (METAL 2013), pp. 376–379

S. Lezhnev, A. Naizabekov, A. Volokitin, and I. Volokitina, New Combined Process Pressing–Drawing and Impact on Properties of Deformable Aluminum Wire, Procedia Eng., 2014, 81, p 1505–1510

N.V. Lopatin, G.A. Salishchev, and S.P. Galkin, Mathematical Modeling of Radial-Shear Rolling of the VT6 Titanium Alloy Under Conditions of Formation of a Globular Structure, Russ. J. Non-Ferrous Met., 2011, 52(5), p 442–447

A.B. Naizabekov, S.N. Lezhnev, H. Dyja, T. Bajor, K. Tsay, A. Arbuz et al., The Effect of Cross Rolling on the Microstructure of Ferrous and Non-ferrous Metals and Alloys, Metalurgija, 2017, 56(1–2), p 199–202

A. Naizabekov, S. Lezhnev, A. Arbuz, and E. Panin, Combined process “helical rolling–pressing” and its effect on the microstructure of ferrous and non-ferrous materials, Metall. Res. Technol., 2018, 115(2), p 213

I.P. Mazur, A.B. Naizabekov, S.N. Lezhnev, E.A. Panin, R.O. Vedichshev, Уcтpoйcтвo для нeпpepывнoгo пpeccoвaния мeтaллoв и cплaвoв (Device for Continuous Pressing of Metals and Alloys), Patent of Russian Federation No. 2629134 (C1), 2017, bulletin No. 24.

A. Naizabekov, S. Lezhnev, E. Panin, and I. Volokitina, New combined technology of deformation “rolling-equal channel angular pressing”, allowing to obtain metals and alloys with sub-ultra-fine-grained structure, Severe Plastic Deformation Techniques, M. Cabibbo, Ed., InTech, Rijeka, 2017, https://doi.org/10.5772/intechopen.68663

A.P. Grudev, Teopия пpoкaтки (Rolling theory), Intermet Engineering, Moscow, 2001

V.L. Kolmogorov, Mexaникa oбpaбoтки мeтaллoв дaвлeниeм (Mechanics of metal forming), USTU-UPI, Ekaterinburg, 2001

ASM International, ASM Metals Handbook Volume 12: Fractography, ASM International, Cleveland, 2002

P.Y. Bryantsev, Investigation and optimization of heat treatment of ingots of alloys of the system Al-Mg-Si. Dissertation on competition of a scientific degree of candidate of technical Sciences, Moscow, 2007

I. Sabirov, M.T. Perez-Prado, M. Murashkin, J.M. Molina-Aldareguia, E.V. Bobruk, N.F. Yunusova et al., Application of Equal Channel Angular Pressing with Parallel Channels for Grain Refinement in Aluminium Alloys and its Effect on Deformation Behavior, Int. J. Mater. Form., 2010, 3(1), p 411–414

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Naizabekov, A., Lezhnev, S., Panin, E. et al. Effect of Combined Rolling–ECAP on Ultrafine-Grained Structure and Properties in 6063 Al Alloy. J. of Materi Eng and Perform 28, 200–210 (2019). https://doi.org/10.1007/s11665-018-3790-z

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-018-3790-z