Abstract

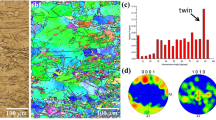

Die-casting AZ31 Mg alloys were successfully friction stir welded at a constant welding speed and different rotation rates. More uniform and fine grains were obtained at the rotation rate of 1400 rpm due to more suitable temperature for dynamic recrystallization in this welding condition. In addition, the intensity of (0001) texture in stir zone increased with the increasing rotation rate. The results of mechanical property test indicated joint with rotation rate of 1400 rpm had better tensile property, which was associated with fine grains, uniform transition in the interface between thermo-mechanically affected zone and stir zone as well as more favorable Schmidt factor for basal slip and twinning. The corrosion resistance of joints increased with the increasing rotation rate, which is significantly related to the (0001) texture with basal plane parallel to the corroded surfaces.

Similar content being viewed by others

References

X.P. Chen, L.X. Wang, R. Xiao, X.Y. Zhong, G.J. Huang, and Q. Liu, Comparison of Annealing on Microstructure and Anisotropy of Magnesium Alloy AZ31 Sheets Processed by Three Different Routes, J. Alloy. Compd., 2014, 604, p 112

A.A. Luo, Magnesium Casting Technology for Structural Applications, J. Magnes. Alloy, 2013, 1, p 2

E. Aghion and B. Bronfin, Magnesium Alloys Development Towards the 21st Century, Mater. Sci. Forum, 2000, 9, p 350

N. Kumar, M. Komarasamy, and R.S. Mishra, Plastic Deformation Behavior of Ultrafine-Grained Al-Mg-Sc Alloy, J. Mater. Sci., 2014, 49, p 4202

J. Yang, D.R. Ni, D. Wang, B.L. Xiao, and Z.Y. Ma, Effects of Rotation Rates on Microstructure, Mechanical Properties, and Fracture Behavior of Friction Stir-Welded (FSW) AZ31 Magnesium Alloy, Mater. Trans. A, 2014, 45, p 2101

G. Padmanaban, V. Balasubramanian, and J.K.S. Sundar, Influences of Welding Processes on Microstructure, Hardness and Tensile Properties of AZ31B Magnesium Alloy, J. Mater. Eng. Perform., 2009, 19, p 155

L. Commin, M. Dumont, J.E. Masse, and L. Barrallier, Friction Stir Welding of AZ31 Magnesium Alloy Rolled Sheets: Influence of Processing Parameters, Acta Mater., 2009, 57, p 326

G. Padmanaban and V. Balasubramanian, Selection of FSW Tool Pin Profile, Shoulder Diameter and Material for Joining AZ31B Magnesium Alloy—An Experimental Approach, Mater. Des., 2009, 30, p 2647

J. Yang, B.L. Xiao, D. Wang, and Z.Y. Ma, Effects of Heat Input on Tensile Properties and Fracture Behavior of Friction Stir Welded Mg-3Al-1Zn Alloy, Mater. Sci. Eng. A, 2010, 527, p 708

S.H.C. Park, Y.S. Sato, and H. Kokawa, Effect of Micro-Texture on Fracture Location in Friction Stir Weld of Mg Alloy AZ61 During Tensile Test, Scr. Mater., 2003, 49, p 161

U.F.H.R. Suhuddin, S. Mironov, Y.S. Sato, H. Kokawa, and C.-W. Lee, Grain Structure Evolution During Friction-Stir Welding of AZ31 Magnesium Alloy, Acta Mater., 2009, 57, p 5406

L. Hou, T. Wang, R. Wu, J. Zhang, M. Zhang, A. Dong, B. Sun, S. Betsofen, and B. Krit, Mircrostructure and Mechanical Properties of Mg-5Li-Al Sheets Prepared by Accumulative Roll Bonding, J. Mater. Sci. Technol., 2018, 34, p 317

Z. Li, F. Liu, A. Yuan, B. Duan, Y. Li, and X. Li, Effect of Rolling Deformation on Microstructure and Texture of Spray-Deposited Magnesium Alloy Containing Mg-Nd-Zn Typed LPSO, J. Mater. Sci. Technol., 2017, 33, p 630

S. Mironov, T. Onuma, Y.S. Sato, S. Yoneyama, and H. Kokawa, Tensile Behavior of Friction-Stir Welded AZ31 Magnesium Alloy, Mater. Sci. Eng. A, 2017, 679, p 272

R. Xin, L. Sun, D. Liu, Z. Zhou, and Q. Liu, Effect of Subsequent Tension and Annealing on Microstructure Evolution and Strength Enhancement of Friction Stir Welded Mg Alloys, Mater. Sci. Eng. A, 2014, 602, p 1

Z. Liu, R. Xin, D. Liu, X. Shu, and Q. Liu, Textural Variation in Triple Junction Region of Friction Stir Welded Mg Alloys and Its Influence on Twinning and Fracture, Mater. Sci. Eng. A, 2016, 658, p 185

D. Liu, R. Xin, H. Yu, Z. Liu, X. Zheng, and Q. Liu, Comparative Examinations on the Activity and Variant Selection During Tension and Compression of Magnesium Alloys, Mater. Sci. Eng. A, 2016, 658, p 229

D. Liu, R. Xin, Y. Xiao, Z. Zhou, and Q. Liu, Strain Localization in Friction Stir Welded Magnesium During Tension and Compression Deformation, Mater. Sci. Eng. A, 2014, 609, p 88

X.B. Liu, D.Y. San, Y.W. Song, R.S. Chen, and E. Han, Influences of the Quantity of Mg2Sn Phase on the Corrosion Behavior of Mg-7Sn Magnesium Alloy, Electrochim. Acta, 2011, 56, p 2582

Y. Li, T. Zhang, and F. Wang, Effect of Microcrystallization on Corrosion Resistance of AZ91D Alloy, Electrochim. Acta, 2006, 51, p 2845

R. Ambat, N.N. Aung, and W. Zhou, Evaluation of Microstructural Effects on Corrosion Behaviour of AZ91D Magnesium Alloy, Corros. Sci., 2000, 42, p 1433

L.M. Peng, J.W. Chang, X.W. Guo, A. Atrens, W.J. Ding, and Y.H. Peng, Influence of Heat Treatment and Microstructure on the Corrosion of Magnesium Alloy Mg-10Gd-3Y-0.4Zr, J. Appl. Electrochem., 2009, 39, p 913

B. Jiang, Q. Xiang, A. Atrens, J. Song, and F. Pan, Influence of Crystallographic Texture and Grain Size on the Corrosion Behaviour of As-Extruded Mg Alloy AZ31 Sheets, Corros. Sci., 2017, 126, p 274

G.L. Song and Z. Xu, Crystal Orientation and Electrochemical Corrosion of Polycrystalline Mg, Corros. Sci., 2012, 63, p 100

M. Liu, D. Qiu, M.C. Zhao, G.L. Song, and A. Atrens, The Effect of Crystallographic Orientation on the Active Corrosion of Pure Magnesium, Scr. Mater., 2008, 58, p 421

F.S. Pan, A. Xu, D. Deng, J.H. Ye, X.Q. Jiang, A. Tang, and Y. Ran, Effects of Friction of Friction Stir Welding on Microstructure and Mechanical Properties of Magnesium Alloy Mg-5Al-3Sn, Mater. Des., 2016, 110, p 266

A. Kouadri-henni and L. Barrallier, Mechanical Properties, Microstructure and Crystallographic Texture of Magnesium AZ91-D Alloy Welded by Friction Stir Welding (FSW), Mater. Trans. A, 2014, 45, p 4983

H. Pan, F. Wang, L. Jin, M. Feng, and J. Dong, Mechanical Behavior and Microstructure Evolution of a Rolled Magnesium Alloy AZ31B Under Low Stress Triaxiality, J. Mater. Sci. Technol., 2016, 32, p 1282

P. Chen, B. Li, D. Culbertson, and Y. Jiang, Contribution of Extension Twinning to Plastic Strain at Low Stress Stage Deformation of a Mg-3Al-1Zn Alloy, Sci. Eng. A, 2018, 709, p 40

L.H. Song, B.L. Wub, L. Zhang, X.H. Du, Y.N. Wang, and C. Esling, Twinning Characterization of Fiber-Textured AZ31B Magnesium Alloy During Tensile Deformation, Sci. Eng. A, 2018, 710, p 57

C. Mo and A. Kontsos, Twinning Contributions to Strain Localizations in Magnesium Alloys, Sci. Eng. A, 2018, 722, p 206

W.D. Callister, Materials Science and Engineering—An Introduction, 7th ed., Wiley, New York, 2007

S.M. Razavi, D.C. Foley, I. Karaman, K.T. Hartwig, O. Duygulu, L.J. Kecskes, S.N. Mathaudhu, and V.H. Hammond, Effect of Grain Size on Prismatic Slip in Mg-3Al-1Zn Alloy, Scr. Mater., 2012, 67, p 439

S.H. Park, S.G. Hong, and C.S. Lee, Activation Mode Dependent 10-12 Twinning Characteristics in a Polycrystalline Magnesium Alloy, Scr. Mater., 2010, 62, p 202

A.D. Atrens, I. Gentle, and A. Atrens, Possible Dissolution Pathways Participating in the Mg Corrosion Reaction, Corros. Sci., 2015, 92, p 173

G.L. Song and Z.Q. Xu, Effect of Microstructure Evolution on Corrosion of Different Crystal Surfaces of AZ31 Mg Alloy in a Chloride Containing Solution, Corros. Sci., 2012, 54, p 97

S. Pawar, T.J.A. Slater, T.L. Burnett, X. Zhou, G.M. Scamans, and Z. Fan, Crystallographic Effects on the Corrosion of Twin Roll Cast AZ31 Mg Alloy Sheet, Acta Mater., 2017, 133, p 90

Acknowledgments

This study was sponsored by the Fund for Shanxi Key Subjects Construction, National Natural Science Foundation of China (No. 51275332), the Natural Science Foundation of Shanxi Province (No. 201601D011036) and Natural Science Youth Foundation of Shanxi Province (No. 2015021130).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Li, Y., Qin, F., Liu, C. et al. Influence of Rotation Rate on Microstructure and Comprehensive Performance of FSWed Mg Alloy. J. of Materi Eng and Perform 27, 5635–5643 (2018). https://doi.org/10.1007/s11665-018-3704-0

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-018-3704-0