Abstract

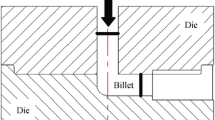

In the present work, cast Al-5Zn-2Mg alloy was processed through equal-channel angular pressing (ECAP) in route BC up to four number of passes. Microstructure and mechanical properties were investigated on processed and unprocessed materials. In cast condition, the material was composed of dendritic structure. After homogenization treatment, large-sized grains were observed. After ECAP processing, significant grain refinement was observed. After ECAP processing, high-density dislocations and high degree of misorientation between the grains were observed. In cast material, rod-shaped precipitates were observed, while, after ECAP processing, spherical-shaped precipitates were observed. ECAP processing leads to a noticeable improvement in the mechanical properties of the material. After four passes, 122% improvement in the microhardness and 135% improvement in the ultimate tensile strength of the material were observed. After three passes, a slight decrease in the mechanical properties was observed. This is attributed to the dissolution of the metastable η′ phase, annihilation of dislocations, dynamic recrystallization and texturing during ECAP processing. Brittle fracture mode was observed in tensile testing cast and homogenized samples. After ECAP processing, fracture mode was changed into shear fracture mode.

Similar content being viewed by others

References

R.Z. Valiev, R.K. Islamgaliev, and I.V. Alexandrov, Bulk Nanostructured Materials from Severe Plastic Deformation, Prog. Mater. Sci., 2000, 45(2), p 103–189

R.Z. Valiev and T.G. Langdon, Principles of Equal-Channel Angular Pressing as a Processing Tool for Grain Refinement, Prog. Mater. Sci., 2006, 51(7), p 881–981

V.M. Segal, V.I. Raznikov, A.E. Drobyshewsky, and V.I. Kopylov, Plastic Working of Metals by Simple Shear, Russ. Metall., 1981, 1, p 99–106

Y.T. Zehetbauer and M.J. Zhu, Bulk Nanostrucutred Materials, Wiley, Hoboken, 2009

M.H. Shaeri, M.T. Salehi, S.H. Seyyedein, M.R. Abutalebi, and J.K. Park, Microstructure and Mechanical Properties of Al-7075 Alloy Processed by Equal Channel Angular Pressing Combined with Aging Treatment, Mater. Des., 2014, 57, p 250–257

K. Gopala Krishna, K. Sivaprasad, T.S.N. Sankara Narayanan, and K.C. Hari Kumar, Localized Corrosion of an Ultrafine Grained Al-4Zn-2Mg Alloy Produced by Cryorolling, Corros. Sci., 2012, 60, p 82–89

K. Gopala Krishna, N. Singh, K. Venkateswarlu, and K.C. Hari Kumar, Tensile Behavior of Ultrafine-Grained Al-4Zn-2Mg Alloy Produced by Cryorolling, J. Mater. Eng. Perform., 2011, 20(9), p 1569–1574

A.A. Mazilkin, O.A. Kogtenkova, B.B. Straumal, R.Z. Valiev, and B. Baretzky, Formation of Nanostructure During High-Pressure Torsion of Al-Zn, Al-Mg and Al-Zn-Mg Alloys, Defect Diffus. Forum, 2005, 237–240, p 739–744

O.A. Kogtenkova, A.A. Mazilkin, B.B. Straumal, G.E. Abrosimova, P. Zięba, T. Czeppe, B. Baretzky, and R.Z. Valiev, Phase Transformations in Al-Mg-Zn Alloys During High Pressure Torsion and Subsequent Heating, J. Mater. Sci., 2013, 48(13), p 4758–4765

A.A. Mazilkin, B. Baretzky, S. Enders, O.A. Kogtenkova, B.B. Straumal, E. Rabkin, and R.Z. Valiev, Hardness of Nanostructured Al-Zn, Al-Mg and Al-Zn-Mg Alloys Obtained by High-Pressure Torsion, Defect Diffus. Forum, 2006, 249, p 155–160

K. Gopala Krishna, K. Sivaprasad, K. Venkateswarlu, and K.C. Hari Kumar, Microstructural Evolution and Aging Behavior of Cryorolled Al-4Zn-2Mg Alloy, Mater. Sci. Eng. A, 2012, 535, p 129–135

S.L. Yang, Q.L. Lin, C. Xu, and J.H. Pan, Investigation on Fatigue Damage and Fracture of Al-5Zn-2Mg High Strength Aluminum Alloy, Appl. Mech. Mater., 2012, 184–185, p 1030–1033

Y. Iwahashi, J. Wang, Z. Horita, M. Nemoto, and T.G. Langdon, Principle of Equal-Channel Angular Pressing for the Processing of UltraFine Grained Materials, Scr. Mater., 1996, 35(2), p 143–146

K. Nakashima, Z. Horita, M. Nemoto, and T.G. Langdon, Development of a Multi-Pass Facility for Equal-Channel Angular Processing to High Total Strains, Mater. Sci. Eng. A, 2000, 281(1–2), p 82–87

M. Furukawa, Z. Horita, and T.G. Langdon, Factors Influencing the Shearing Patterns in Equal-Channel Angular Pressing, Mater. Sci. Eng. A, 2002, 332(1–2), p 97–109

O. Alvarez, C. Gonzalez, G. Aramburo, R. Herrera, and J.A. Juarez-islas, Characterization and Prediction of Microstructure in Al-Zn-Mg Alloys, Mater. Sci. Eng. A, 2005, 402(1–2), p 320–324

S. Zhang, W. Hu, R. Berghammer, and G. Gottstein, Microstructure Evolution and Deformation Behavior of Ultrafine-Grained Al-Zn-Mg Alloys with Fine η′ Precipitates, Acta Mater., 2010, 58(20), p 6695–6705

K.R. Cardoso, D.N. Travessa, W.J. Botta, and A.M. Jorge, Jr., High Strength AA7050 Al Alloy Processed by ECAP: Microstructure and Mechanical Properties, Mater. Sci. Eng. A, 2011, 528(18), p 5804–5811

S.D. Terhune, D. Swisher, K. Oh-Ishi, Z. Horita, T.G. Langdon, and T.R. McNelley, An Investigation of Microstructure and Grain-Boundary Evolution During ECA Pressing of Pure Aluminum, Metall. Mater. Trans. A, 2002, 33(7), p 2173–2184

C. Xu, M. Furukawa, Z. Horita, and T.G. Langdon, Using ECAP to Achieve Grain Refinement, Precipitate Fragmentation and High Strain Rate Superplasticity in a Spray-Cast Aluminum Alloy, Acta Mater., 2003, 51(20), p 6139–6149

C. Xu, M. Furukawa, Z. Horita, and T.G. Langdon, Influence of ECAP on Precipitate Distributions in a Spray-Cast Aluminum Alloy, Acta Mater., 2005, 53(3), p 749–758

S.R. Kumar, K. Gudimetla, P. Venkatachalam, B. Ravisankar, and K. Jayasankar, Microstructural and Mechanical Properties of Al 7075 Alloy Processed by Equal Channel Angular Pressing, Mater. Sci. Eng. A, 2012, 533, p 50–54

Y.H. Zhao, X.Z. Liao, Z. Jin, R.Z. Valiev, and Y.T. Zhu, Microstructures and Mechanical Properties of Ultrafine Grained 7075 Al Alloy Processed by ECAP and Their Evolutions During Annealing, Acta Mater., 2004, 52(15), p 4589–4599

J. Gubicza, I. Schiller, N.Q. Chinh, J. Illy, Z. Horita, and T.G. Langdon, The Effect of Severe Plastic Deformation on Precipitation in Supersaturated Al-Zn-Mg Alloys, Mater. Sci. Eng. A, 2007, 460–461, p 77–85

M.H. Shaeri, M. Shaeri, M.T. Salehi, S.H. Seyyedein, and M.R. Abutalebi, Effect of Equal Channel Angular Pressing on Aging Treatment of Al-7075 Alloy, Prog. Nat. Sci. Mater. Int., 2015, 25(2), p 159–168

L.J. Zheng, H.X. Li, M.F. Hashmi, C.Q. Chen, Y. Zhang, and M.G. Zeng, Evolution of Microstructure and Strengthening of 7050 Al Alloy by ECAP Combined with Heat-Treatment, J. Mater. Process. Technol., 2006, 171(1), p 100–107

W.J. Kim, J.K. Kim, H.K. Kim, J.W. Park, and Y.H. Jeong, Effect of Post Equal-Channel-Angular-Pressing Aging on the Modified 7075 Al Alloy Containing Sc, J. Alloys Compd., 2008, 450(1–2), p 222–228

S.G. Chowdhury, C. Xu, and T.G. Langdon, Texture Evolution in an Aluminum Alloy Processed by ECAP with Concurrent Precipitate Fragmentation, Mater. Sci. Eng. A, 2008, 473(1–2), p 219–225

A. Muralidhar, S. Narendranath, and H. Shivananda Nayaka, Effect of Equal Channel Angular Pressing on AZ31 Wrought Magnesium Alloys, J. Magnes. Alloy., 2013, 1(4), p 336–340

K.R. Gopi, H. Shivananda Nayaka, and S. Sahu, Investigation of Microstructure and Mechanical Properties of ECAP-Processed AM Series Magnesium Alloy, J. Mater. Eng. Perform., 2016, 25(9), p 3737–3745

P. Lukáč and J. Balík, Kinetics of Plastic Deformation, Key Eng. Mater., 1994, 97–98, p 307–322

G. Purcek, M. Aydin, O. Saray, and T. Kucukomeroglu, Enhancement of Tensile Ductility of Severe Plastically Deformed Two-Phase Zn-12Al Alloy by Equal Channel Angular Extrusion, Mater. Sci. Forum, 2009, 633–634, p 437–447

B. Pourbahari, H. Mirzadeh, and M. Emamy, The Effects of Grain Refinement and Rare Earth Intermetallics on Mechanical Properties of As-Cast and Wrought Magnesium Alloys, J. Mater. Eng. Perform., 2018, 27(3), p 1327–1333

A. Ma, N. Saito, M. Takagi, Y. Nishida, H. Iwata, K. Suzuki, I. Shigematsu, and A. Watazu, Effect of Severe Plastic Deformation on Tensile Properties of a Cast Al-11 mass% Si Alloy, Mater. Sci. Eng. A, 2005, 395(1–2), p 70–76

M.I.A. El Aal, Influence of the Pre-homogenization Treatment on the Microstructure Evolution and the Mechanical Properties of Al-Cu Alloys Processed by ECAP, Mater. Sci. Eng. A, 2011, 528(22–23), p 6946–6957

Z.C. Duan, N.Q. Chinh, C. Xu, and T.G. Langdon, Developing Processing Routes for the Equal-Channel Angular Pressing of Age-Hardenable Aluminum Alloys, Metall. Mater. Trans. A, 2010, 41(4), p 802–809

D.R. Fang, Q.Q. Duan, N.Q. Zhao, J.J. Li, S.D. Wu, and Z.F. Zhang, Tensile Properties and Fracture Mechanism of Al-Mg Alloy Subjected to Equal Channel Angular Pressing, Mater. Sci. Eng. A, 2007, 459(1–2), p 137–144

M.I.A. El Aal, N. El Mahallawy, F.A. Shehata, M.A. El Hameed, E.Y. Yoon, J.H. Lee, and H.S. Kim, Tensile Properties and Fracture Characteristics of ECAP-Processed Al and Al-Cu Alloys, Met. Mater. Int., 2010, 16(5), p 709–716

O. Saray and G. Purcek, Microstructural Evolution and Mechanical Properties of Al-40 wt.% Zn Alloy Processed by Equal-Channel Angular Extrusion, J. Mater. Process. Technol., 2009, 209(5), p 2488–2498

A. Vinogradov, T. Ishida, K. Kitagawa, and V.I. Kopylov, Effect of Strain Path on Structure and Mechanical Behavior of Ultra-Fine Grain Cu-Cr Alloy Produced by Equal-Channel Angular Pressing, Acta Mater., 2005, 53(8), p 2181–2192

Acknowledgments

One of the authors Mr. G.K. Manjunath would like to thank the Director, National Institute of Technology Karnataka and MHRD-Government of India for providing Institute Research Fellowship.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Manjunath, G.K., Preetham Kumar, G.V., Udaya Bhat, K. et al. Microstructure and Mechanical Properties of Cast Al-5Zn-2Mg Alloy Subjected to Equal-Channel Angular Pressing. J. of Materi Eng and Perform 27, 5644–5655 (2018). https://doi.org/10.1007/s11665-018-3691-1

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-018-3691-1