Abstract

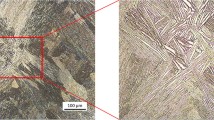

The article gives results of structure formation in metallic materials after different types of deformation: tungsten after rolling, nickel after thermal cycling and nickel single crystal after rolling, aluminum single crystal after cyclic tension and aluminum alloys (D16, 2024-T3) after impulsive load. We used optical and electron microscopy methods for investigation of deformation structure formation and molecular dynamics method for computer modeling of the processes of plastic deformation (LAMMPS software). The following quantitative parameters were calculated during the simulation: energy of pair interaction, temperature, total cumulative pressure, stress tensor and pressure tensor. The study shows that the plastic flow of metallic materials with any initial structure at certain loading stage can be carried out by homogeneous mass transfer through channels with a liquid-like structure, from which follows that the dislocation mechanism of plastic deformation of crystals has a limited field of application. The main role has a synergistic structure formation in the conditions of distance from thermodynamic equilibrium. The relaxation processes proceed intensively after and during the process of destruction. The results of modeling have shown the possibility of forming channels of hydrodynamic flow without the participation of defects in the initial material.

Similar content being viewed by others

References

G. Nicolis and I. Prigogine, Self-Organization in Nonequilibrium Systems From Dissipative Structures to Order Through Fluctuations, Wiley, New York, 1977, p 491

H. Haken, Synergetics, Naturwissenschaften, Springer, Berlin, 1980, p 405 (in German)

W. Ebeling, Strukturbildung bei irreversiblen Prozessen: eine EinfuĖhrung in die Theorie dissipativer Strukturen (Teubner, 1966), p. 194 (in German)

J. Friedel, Les Dislocations (Gauthier. Villars, Paris, 1956), p. 314 (in French)

P.N. Antciforov, E.E. Zasimchuk, I.K. Zasimchuk, and S.M. Kaverina, Influence of Deformation Strengthening on Structural Changes During of Ni Heat Cycling, Metalphysics, 1981, 3(5), p 64–73 (in Russian)

E.E. Zasimchuk and L.I. Markashova, Microbands in Rolling-Deformed Nickel Single Crystals, Mater. Sci. Eng. A, 1990, 127(1), p 33–39. https://doi.org/10.1016/0921-5093(90)90186-7

A.S. Malin and M. Hatherly, Microstructure of Cold-Rolled Copper, Met. Sci., 1979, 13(8), p 463–472

Yu.G. Gordienko, E.E. Zasimchuk, and R.G. Gontareva, Unconventional Deformation Modes and Surface Roughness Evolution in Al Single Crystals Under Restricted Cyclic Tension Conditions, J. Mater. Sci. Lett., 2003, 22, p 241–245

E.E. Zasimchuk, Yu.G. Gordienko, R.G. Gontareva, and I.K. Zasimchuk, Equidimensional Fractal Maps for Indirect Estimation of Deformation Damage in Nonuniform Aircraft Alloys, J. Mater. Eng. Perform., 2003, 12(1), p 69–76

Yu.G. Gordienko and E.E. Zasimchuk, Synergetic Model of Structure Formation During Plastic Deformation of Crystals, Philos. Mag. A, 1994, 70(1), p 99–107

E.E. Zasimchuk, V.I. Zasimchuk, and T.V. Turchak, Self Organization of Crystals during Plastic Deformation, Uspehi fiziki metallov, 2013, 14(3), p 275–318 (in Russian)

E. Zasimchuk, L. Markashova, A. Bakova, T. Turchak, N. Chausov, V. Hutsaylyuk, and V. Berezin, Influence of Combined Loading on Microstructure and Properties of Aluminum Alloy 2024-T3, Mater. Eng. Perform., 2013, 22(7), p 3421–3429. https://doi.org/10.1007/s11665-013-0630-z

E. Zasimchuk, T. Turchak, A. Baskova, N. Chausov, and V. Hutsaylyuk, Structural Transformation in Metallic Materials During Plastic Deformation, Mater. Eng. Perform., 2017, 26(3), p 1293–1299. https://doi.org/10.1007/s11665-017-2564-3

S.M. Foiles, M.I. Baskes, and M.S. Daw, Embedded-Atom-Method Functions for the fcc Metals Cu, Ag, Au, Ni, Pd, Pt, and Their Alloys, Phys. Rev. B, 1986, 33(12), p 7983–7991

K.W. Jacobsen, J.K. Norskov, and M.J. Puska, Interatomic Interactions in the Effective-Medium Theory, Phys. Rev. B, 1987, 35(14), p 7423–7442

M. Kiritani, Dislocation-Free Plastic Deformation Under High Stress, Mater. Sci. Eng. A, 2003, 350(1–2), p 1–7. https://doi.org/10.1016/S0921-5093(02)00685-8

A. Stukowski, Visualization and Analysis of Atomistic Simulation Data with OVITO—The Open Visualization Tool. Sim. Mater. Sci. Eng., 2010, 18(1), p 015012-1–015012-7

M.S. Daw and M.I. Baskes, Embedded-Atom Method: Derivation and Application to Impurities, Surfaces, and Other Defects in Metals. Phys. Rev. B, 1984, 29, p 6443–6453

M. Finnis, Interatomic Forces in Condensed Matter, Oxford University Press, Oxford, 2003

S. Plimpton, Fast Parallel Algorithms for Short-Range Molecular Dynamics, J. Comp. Phys., 1995, 117(1), p 1–19

A.P. Thompson, S.J. Plimpton, and W. Mattson, General Formulation of Pressure and Stress Tensor for Arbitrary Many-Body Interaction Potentials Under Periodic Boundary Conditions, J. Chem. Phys., 2009, 131, p 154107

A.K. Subramaniyan and C.T. Sun, Continuum Interpretation of Virial Stress in Molecular Simulations, Int. J. Solids Struct., 2008, 14, p 4340–4346

H. Tsuzuki, P. Branicio, and J. Rino, Structural Characterization of Deformed Crystals by Analysis of Common Atomic Neighborhood, Comp. Phys. Comm., 2007, 177, p 518–523

M. Wojdyr, Y. Mo, E. Grzanka, S. Stelmakh, S. Gierlotka, T. Proffen, and I. Szlufarska, Transition of nc-SiC Powder Surface Into Grain Boundaries During Sintering by Molecular Dynamics Simulation and Neutron Powder Diffraction, Z. Kristallogr., 2007, 26(Suppl), p 255–260

M.A. Krivoglaz, Difraktsiya Rentgenovskikh Luchey i Neytronov v Neideal’nykh Kristallakh (Naukova Dumka, Kiev 1983), p. 408 (in Russian)

L.D. Landau and E.M. Lifshits, Theoretical Physics, Vol.VI. Hydrodynamics, Nauka, Moscow, 1988 (in Russian)

R. Berner and H. Kronmuller, Plastische Verfomung von Einkristallen, Springer, Berlin, 1965, p 270 (in German)

Author information

Authors and Affiliations

Corresponding author

Appendix

Appendix

- Q :

-

is amount of material released to the surface through the surface cross section of the channel during the time t;

- e :

-

deformation (e ~ ϴ);

- λ :

-

is the initial length of the channel;

- \(\sigma \left( t \right) = \sigma_{zz}\) :

-

is the component of the tensile stress, which is applied to the sample (all other components are equal to zero);

- P :

-

is the pressure of the “liquid”;

- γ :

-

is the kinematic viscosity;

- ρ :

-

is the density of the “liquid”;

- η :

-

is the coefficient of dynamic viscosity of the “liquid”;

- D :

-

is the integration constant [D = D(t)];

- l :

-

is the length of the channel;

- k, k1, k2:

-

that do not depend on any variable;

- b, b′:

-

are constants;

- q :

-

is the cyclic load frequency;

- y :

-

is the cyclic loading phase;

- r 0 :

-

is the radius of the section of the hydrodynamic channel;

- r :

-

is the coordinate along the radius of the section of the hydrodynamic channel;

- v r :

-

is the velocity of movement of the “fluid” within the channel along the coordinate;

- φ :

-

is the rotation angle in the XOY plane;

- v φ :

-

is the “fluid velocity” along the coordinate φ;

- v z :

-

is the “fluid velocity” along the axis OZ

Rights and permissions

About this article

Cite this article

Zasimchuk, E., Baskova, O., Gatsenko, O. et al. Universal Mechanism of Viscoplastic Deformation of Metallic Materials Far from Thermodynamics Equilibrium. J. of Materi Eng and Perform 27, 4183–4196 (2018). https://doi.org/10.1007/s11665-018-3515-3

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-018-3515-3