Abstract

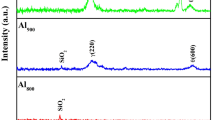

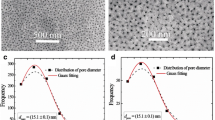

Oxidation of aluminum nitride (AlN) ceramic substrates doped with 2 wt.% Y2O3 was performed in air at temperatures ranging from 1000 to 1300 °C for various lengths of time. Microstructure, bending strength, and thermal conductivity of the oxidized AlN substrates were studied experimentally and also via mathematical models. The results show that the oxide layer formed on the AlN substrates is composed of α-Al2O3 nanocrystallines and interconnected micropores. Longitudinal and transverse cracks are induced in the oxide layer under tensile and shear stresses, respectively. Intergranular oxidation of the AlN grains close to the oxide layer/AlN interface also occurs, leading to widening and cracking of the AlN grain boundaries. These processes result in the monotonous degradation of bending strength and thermal conductivity of the oxidized AlN substrates. Two mathematic models concerning these properties of the oxidized AlN substrates versus the oxide layer thickness were put forward. They fit well with the experimental results.

Similar content being viewed by others

References

K.A. Khor, L.G. Yu, and Y. Murakoshi, Spark Plasma Sintering of Sm2O3-doped Aluminum Nitride, J. Eur. Ceram. Soc., 2005, 25, p 1057–1065

J. Schulz-Harder, Advantages and New Development of Direct Bonded Copper Substrates, Microelectron. Reliab., 2003, 43, p 359–365

W. Grzesiak, P. MaćKów, T. Maj, B. Synkiewicz, K. Witek, R. Kisiel, M. Myśliwiec, J. Borecki, T. Serzysko, and M. Żupnik, Application of Direct Bonded Copper Substrates for Prototyping of Power Electronic Modules, Circuit World, 2016, 42, p 23–31

W.M. Yim and R.J. Paff, Thermal Expansion of AlN, Sapphire, and Silicon, J. Appl. Phys., 1974, 45, p 1456–1457

J. Zhan, Y. Cao, H. Zhang, J. Guo, J.H. Zhang, C.L. Geng, C.D. Shi, S. Cui, and W.M. Tang, Low-temperature Sintering of AlN Ceramics by Sm2O3-Y2O3-CaO Sintering Additives Formed via Decomposition of Nitrate Solutions, J. Mater. Eng. Perform., 2017, 26, p 453–459

C.T. Yeh and W.H. Tuan, Accelerating the Oxidation Rate of AlN Substrate through the Addition of Water Vapor, J. Asian Ceram. Soc., 2017, 5, p 381–384

C.T. Yeh and W.H. Tuan, Pre-oxidation of AlN Substrates for Subsequent Metallization, J. Mater. Sci.: Mater. Electron., 2015, 26, p 5910–5916

H.E. Kim and A.J. Moorhead, Oxidation Behavior and Flexural Strength of Aluminum Nitride Exposed to Air at Elevated Temperatures, J. Am. Ceram. Soc., 1994, 77, p 1037–1041

C.W. Cao, Y.B. Feng, T. Qiu, and T. Liang, Surface Oxidation and Metallization of AlN Ceramics by Mo-Mn Process, J. Syn. Cryst., 2017, 46, p 416–421

C.T. Yeh and W.H. Tuan, Oxidation Mechanism of Aluminum Nitride Revisited, J. Adv. Ceram., 2017, 6, p 27–32

C. Xu and W. Gao, Pilling–Bedworth Ratio for Oxidation of Alloys, Mater. Res. Innov., 2000, 3, p 231–235

E.W. Osborne and M.G. Norton, Oxidation of Aluminium Nitride [J], J. Mater. Sci., 1998, 33, p 3859–3865

M.D. Drory, M.D. Thouless, and A.G. Evans, On the Decohesion of Residually Stressed Thin Films, Acta Metall., 1988, 36, p 2019–2028

M.D. Drory and A.G. Evans, Experimental Observations of Substrate Fracture Caused by Residually Stressed Films, J. Am. Ceram. Soc., 1990, 73, p 634–638

C.W. Cao, Y.B. Feng, T. Qiu, J. Yang, X.Y. Li, T. Liang, and J. Li, Effects of Isothermal Annealing on the Oxidation Behavior, Mechanical and Thermal Properties of AlN Ceramics, Ceram. Int., 2017, 43, p 9334–9342

R.C. West, CRC Handbook of Chemistry and Physics, CPC Press Inc, Boca Raton, 1982

J.Y. Wu, F. Chen, Q. Shen, and L.M. Zhang, Effect of Thermal Conductivity and Analytical Calculation Method of Effective Thermal Conductivity for Porous Ceramics, Adv. Ceram., 2011, 4, p 13–16

D.A.G. Bruggeman, Berechnung verschiedener physikalischer Konstanten von heterogenen Substanzen: I. Dielektrizitätskonstanten und Leitfähigkeiten der Mischkörper aus isotropen Substanzen, Ann. der Phys., 1935, 416, p 160–178

R. Landauer, The Electrical Resistance of Binary Metallic Mixtures, J. Appl. Phys., 1952, 23, p 779–784

Z.D. Guan, Z.T. Zhang, and J.S. Jiao, Physical Properties of Inorganic Materials, 2nd ed., Tsinghua University Press, Beijing, 2011

G. Ji, Z. Chen, M.L. Wang, A. Addad, D. Schryvers, and H.W. Wang, Fabrication, Interface Characterization and Modeling of Oriented Graphite Flakes/Si/Al Composites for Thermal Management Applications, Mater. Des., 2014, 63, p 719–728

H.V. Truong and G.E. Zinsmeister, Experimental Study of Heat Transfer in Layered Composites, Int. J. Heat Mass Trans., 1978, 21, p 905–909

R.C. Progelhof, J.L. Throne, and R.R. Ruetsch, Methods for Predicting the Thermal Conductivity of Composite Systems: A Review, Polym. Eng. Sci., 1976, 16, p 615–625

Acknowledgments

This work was financially supported by Projects of Scientific and Technological Research, Anhui Province, China (Grants Nos. 15czz02047, 1604a0902162).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Cao, Y., Xu, H., Zhan, J. et al. Experimental and Modeling Studies on the Microstructures and Properties of Oxidized Aluminum Nitride Ceramic Substrates. J. of Materi Eng and Perform 27, 3297–3303 (2018). https://doi.org/10.1007/s11665-018-3415-6

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-018-3415-6