Abstract

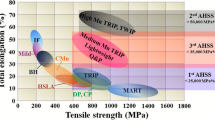

In order to ensure crash resistance of the steels used in automotive components, the ensile deformation behavior needs to be studied and predicted not only under quasi-static condition, but also under dynamic loading rates. In the present study, tensile tests have been performed on four different automobile grade sheet steels, namely interstitial free steel, dual-phase 600 and 800, and a carbon manganese steel over the strain rate regime of 0.001-800/s. Apart from the variation in strength (which always increased with strain rate), the effect of strengthening mechanism on strain rate sensitivity and strain hardening behavior has been evaluated. Strain rate sensitivity was found to increase at high-strain rate regime for all the steels. Contribution of solid solution hardening on strain rate sensitivity at lower plastic strains was found to be higher compared to dislocation strengthening and second-phase hardening. However, precipitation hardening coupled with solid solution hardening produced the highest strain rate sensitivity, in C-Mn-440 steel at high strain rates. Different strain-rate-sensitive models which take into account the change in yield stress and strain hardening behavior with strain rate for ductile materials were used to predict the flow behavior of these sheet steels at strain rates up to 800/s.

Similar content being viewed by others

References

M.S. Rashid, A Unique High-Strength Sheet Steel with Superior Formability, 1976, SAE Preprint No. 760206.

C.D. Horvath, Advanced Steels for Lightweight Automotive Structures, Materials, Design and Manufacturing for Lightweight Vehicles, 1st Ed, Woodhead Publishing Ltd., 2010, p 35–78

Y. Okitsu and N. Tsuji, Effect of Ferrite Grain Size on Dynamic Tensile Properties of Ultrafine Grained Low Carbon Steels with Various Chemical Compositions, Mater. Trans., 2014, 55, p 78–84

A. Uenishi and C. Teodosiu, Solid Solution Softening at High Strain Rates in Si- and/or Mn-Added Interstitial Free Steels, Acta Mater., 2003, 51, p 4437–4446

A. Uenishi, C. Teodosiu, and E.V. Nesterova, Microstructural Evolution at High Strain Rates in Solution-Hardened Interstitial Free Steels, Mater. Sci. Eng., A, 2005, 400-401, p 499–503

S. Oliver, T.B. Jones, and G. Fourlaris, Dual Phase Versus TRIP Strip Steels: Comparison of Dynamic Properties for Automotive Crash Performance, Mater. Sci. Technol., 2007, 23, p 423–431

H. Hoon, K. Seok-Bong, S. Jung-Han and L. Ji-Ho, Dynamic Tensile Characteristics of TRIP-Type and DP-Type Steel Sheets for an auto-Body, Int. J. Mech. Sci., 2008, 50, p 918–931

W. Wang, M. Li, C. He, X. Wei, D. Wang, and H. Du, Experimental Study on High Strain Rate Behavior Of High Strength 600–1000 MPa Dual Phase Steels and 1200 MPa Fully Martensitic Steels, Mater. Des., 2013, 47, p 510–521

N.D. Beynon, T.B. Jones, and G. Fourlaris, Effect of High Strain Rate Deformation on Microstructure of Strip Steels Tested Under Dynamic Tensile Conditions, Mater. Sci. Technol., 2005, 21, p 103–112

V. Tarigopula, O.S. Hopperstad, M. Langseth, A.H. Clausen, and F. Hild, A Study of Localisation in Dual-Phase High-Strength Steels Under Dynamic Loading Using Digital Image Correlation and FE Analysis, Int. J. Solids Struct., 2008, 45, p 601–619

Y.F. Shen, N. Jia, R.D.K. Misra, and L. Zuo, Softening Behavior by Excessive Twinning and Adiabatic Heating at High Strain Rate in a Fe–20Mn–0.6C TWIP Steel, Acta Mater., 2016, 103, p 229–242

A. Uenishi, H. Yoshida, S. Yonemura, S. Hiwatashi, S. Hirose, and N. Suzuki, High Strain Rate Properties of High Strength Steel, Int. J. Autom. Eng., 2011, 2, p 109–113

P.K.C. Wood and C.A. Schley, Strain Rate Testing of Metallic Materials and their Modelling for use in CAE Based Automotive Crash Simulation Tools (Recommendations and procedures), Smithers Rapra Press, 2009.

ASTM, ASTM-E8/8 M, Standard Test Methods for Tension Testing of Metallic Materials, ASTM International, West Conshohocken, 2003

ISO, ISO 26203-2, Metallic Materials—Tensile Testing at High Strain Rates—Part 2: Servo-Hydraulic and Other Test Systems, International Organization for Standardization, Geneva, 2011

H. Huha, S. Kim, J. Song, and J. Lim, Dynamic Tensile Characteristics of TRIP-Type and DP-Type Steel Sheets for an Auto-Body, Int. J. Mech. Sci., 2008, 50, p 918–931

M. Kuroda, A. Uenishi, H. Yoshida, and A. Igarashi, Ductility of Interstitial-Free Steel Under High Strain Rate Tension: Experiments and Macroscopic Modelling with a Physically-Based Consideration, Int. J. Solids Struct., 2006, 43, p 4465–4483

G.E. Dieter, Mechanical Metallurgy, SI, Metric Edition, Mc-Graw Hill book company, London, 1988

J.G. Speer and D.K. Matlock, Constitutive Behavior of High Strength Multiphase Sheet Steels Under High Strain Rate Deformation Conditions, 2005, Final Report, AISI/DOE Project 9904.

F.B. Pickering, Physical Metallurgy and the Design of Steels, Applied Science Publishers Limited, London, 1978

M. Singh, A. Das, T. Venugopalan, K. Mukherjee, M. Walunj, T. Nanda, and B.R. Kumar, Impact of Martensite Spatial Distribution on Quasi-Static and Dynamic Deformation Behavior of Dual-Phase Steel, Metall. Mater. Trans. A; 2018, 49(2), p 463–475.

R. Kapoor and S. Nemat-Nasser, Determination of Temperature Rise During High Strain Rate Deformation, Mech. Mater., 1998, 27, p 1–12

S. Curtzea, V.-T. Kuokkala, M. Hokka, and P. Peura, Deformation Behavior of TRIP and DP Steels in Tension at Different Temperatures Over a Wide Range of Strain Rates, Mater. Sci. Eng., A, 2009, 507, p 124–131

G.R. Johnson and W.H. Cook, A Constitutive Model and Data for Metals Subjected to Large Strains, High Strain Rates and High Temperatures, The 7th International Symposium on Ballistic, 1983, p. 541.

A. Bag, K.K. Ray, and E.S. Dwarakadasa, Influence of Martensite Content and Morphology on Tensile and Impact Properties of High-Martensite Dual-Phase Steels, Metall. Mater. Trans. A, 1999, 30, p 1193–1202

A. Das, M. Ghosh, S. Tarafder, S. Sivaprasad, and D. Chakrabarti, Micromechanisms of Deformation in Dual Phase Steels at High Strain Rates, Mater. Sci. Eng., A, 2017, 680, p 249–258

F.J. Zerilli and R.W. Armstrong, Dislocation-Mechanics-Based Constitutive Relations for Material Dynamics Calculations, J. Appl. Phys., 1987, 61, p 1816–1825

G.R. Cowper and P.S. Symonds, Strain Hardening and Strain Rate Effects in the Impact Loading of Cantilever Beams. Brown University, Appl. Math. Rep., 1958, 28, p 1–46

L. Kaps, H.J. Lipowsky, M. Meywerk M, H. Werner, and S.-P. Scholz, Auswerteverfahren zur. Weiterverarbeitung von Versuchsdaten, 1999. VDEH working Group Intern, Communication, Germany

H. Zhao, A Constitutive Model for Metals Over a Large Range of Strain Rates Identification for Mild-Steel and Aluminium Sheets, Mater. Sci. Eng., A, 1997, 230, p 95–99

A.S. Khan and R. Liang, Behaviors of Three BCC Metal Over a Wide Range of Strain Rates and Temperatures: Experiments and Modeling, Int. J. Plast, 1999, 15, p 1089–1109

W. Bleck, P. Larour, and P. Vanduynslager Crash Relevant Properties and Dynamic Denting of Pre-strained or Pre-loaded High Strength Steels for Automotive Parts, 2006, EUR 22380 EN 2006.

S.K. Paul, A. Raj, P. Biswas, G. Manikandan, and R.K. Verma, Tensile flow Behavior of Ultra Low Carbon, Low Carbon and Micro Alloyed Steel Sheets for Auto Application Under Low to Intermediate Strain Rate, Mater. Des., 2014, 57, p 211–217

D. Samantaray, S. Mandal, U. Borah, A.K. Bhaduri, and P.V. Sivaprasad, A Thermo-Viscoplastic Constitutive Model to Predict Elevated-Temperature Flow Behaviour in a Titanium-Modified Austenitic Stainless Steel, Mater. Sci. Eng., A, 2009, 526, p 1–6

G.T. Gray, III, High-Strain-Rate Deformation: Mechanical Behavior and Deformation Substructures Induced, Annu. Rev. Mater. Res., 2012, 42, p 285–303

P.S. Follansbee and G.T. Gray, III, An Analysis of the Low Temperature, Low and High Strain-Rate Deformation of Ti–6Al–4V, Metall. Mater. Trans. A, 1989, 20, p 863–874

E. Cerreta, C.A. Yablinsky, G.T. Gray, III, S.C. Vogel, and D.W. Brown, The Influence of Grain Size and Texture on the Mechanical Response of High Purity Hafnium, Mater. Sci. Eng., A, 2007, 456, p 243–251

A. Rusinek, R. Zaera, and J.R. Klepaczko, Constitutive Relations in 3-D for a Wide Range of Strain Rates and Temperatures—Application to Mild Steels, Int. J. Solids Struct., 2007, 44, p 5611–5634

E. El-Magd and M. Abouridouane, Influence of Strain Rate and Temperature on the Flow Behaviour of Magnesium Alloy AZ80, Z. Metallkd., 2001, 92(11), p 1231–1235

Acknowledgment

The authors are grateful to Tata Steel Ltd., Jamshedpur, for providing the financial support to carry out the project work in CSIR-NML, Jamshedpur.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Das, A., Biswas, P., Tarafder, S. et al. Effect of Strengthening Mechanism on Strain-Rate Related Tensile Properties of Low-Carbon Sheet Steels for Automotive Application. J. of Materi Eng and Perform 27, 3709–3722 (2018). https://doi.org/10.1007/s11665-018-3405-8

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-018-3405-8