Abstract

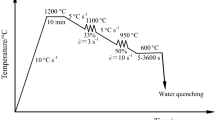

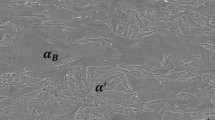

In the present study, the influence of cooling rates (low to ultrafast) on diffusion controlled and displacive transformation of Ti-Nb IF and microalloyed steels has been thoroughly investigated. Mechanisms of nucleation and formation of non-equiaxed ferrite morphologies (i.e., acicular ferrite and bainitic ferrite) have been analyzed in details. The continuous cooling transformation behavior has been studied in a thermomechanical simulator (Gleeble 3800) using the cooling rates of 1-150 °C/s. On the basis of the dilatometric analysis of each cooling rate, continuous cooling transformation (CCT) diagrams have been constructed for both the steels to correlate the microstructural features at each cooling rate in different critical zones. In the case of the IF steel, massive ferrite grains along with granular bainite structures have been developed at cooling rates > 120 °C/s. On the other hand, a mixture of lath bainitic and lath martensite structures has been formed at a cooling rate of ~ 80 °C/s in the microalloyed steel. A strong dependence of the cooling rates and C content on the microstructures and mechanical properties has been established. The steel samples that were fast cooled to a mixture of bainite ferrite and martensite showed a significant improvement of impact toughness and hardness (157 J, for IF steel and 174 J for microalloyed steel) as compared to that of the as-received specimens (133 J for IF steel and 116 J for microalloyed steel). Thus, it can be concluded that the hardness and impact toughness properties are correlated well with the microstructural constituents as indicated by the CCT diagram. Transformation mechanisms and kinetics of austenitic transformation to different phase morphologies at various cooling rates have been discussed in details to correlate microstructural evolution and mechanical properties.

Similar content being viewed by others

References

R. Kuziak, T. Bołd, and Y. Cheng, Microstructure Control of Ferrite-Pearlite High Strength Low Alloy Steels Utilizing Microalloying Additions, J. Mater. Process. Technol., 1995, 53, p 255–262

T. Gladman, The Physical Metallurgy of Microalloyed Steels, The Institute of Materials, London, 1997

S. Ghosh and S. Mula, Thermomechanical Processing of Low Carbon Nb-Ti Stabilized Microalloyed Steel: Microstructure and Mechanical Properties, Mater. Sci. Eng. A, 2015, 646, p 218–233

Y. Maehara and N. Mizui, Physical Metallurgy of IF Steels, Tokyo, ISIJ, 1993, p 233

S. Hoile, Processing and Properties of Mild Interstitial Free Steels, Mater. Sci. Technol., 2000, 16, p 1079–1093

R.K. Ray and P. Ghosh, An Overview on Precipitation and Texture Formation in IF and IFHS Steels During Processing, Mater. Manuf. Process., 2010, 25, p 195–201

S. Ghosh, A.K. Singh, S. Mula, P. Chanda, V.V. Mahashabde, and T.K. Roy, Mechanical Properties, Formability and Corrosion Resistance of Thermomechanically Controlled Processed Ti-Nb Stabilized IF Steel, Mater. Sci. Eng. A, 2017, 684, p 22–36

H.K.D.H. Bhadeshia, The Bainite Transformation: Unresolved Issues, Mater. Sci. Eng. A, 1999, 273–275, p 58–66

H.K.D.H. Bhadeshia, Bainite in Steels: Transformations, Microstructure and Properties, IOM Communications Ltd., London, 2001

F.R. Xiao, B. Liao, and Y.Y. Shan, Challenge of Mechanical Properties of an Acicular Ferrite Pipeline Steel, Mater. Sci. Eng. A, 2006, 431, p 41–52

W. Wang, W. Yan, and L. Zhu, Relation Among Rolling Parameters, Microstructures and Mechanical Properties in an Acicular Ferrite Pipeline Steel, Mater. Des., 2009, 30, p 3436–3443

F. Xiao, B. Liao, and D. Ren, Acicular Ferritic Microstructure of a Low-Carbon Mn-Mo-Nb Microalloyed Pipeline Steel, Mater. Charact., 2005, 54, p 305–314

P. Gong, E.J. Palmiere, and W.M. Rainforth, Dissolution and Precipitation Behavior in Steels Microalloyed with Niobium During Thermomechanical Processing, Acta Mater., 2015, 97, p 392–403

S.W. Thompson, D.J. Colvin, and G. Krauss, Continuous Cooling Transformations and Microstructures in a Low-Carbon, High Strength Low Alloy Plate Steel, Metall. Trans. A, 1990, 21, p 1493–1507

Y. Chen, L. Chen, X. Zhou, Y. Zhao, X. Zha, and F. Zhu, Effect of Continuous Cooling Rate on Transformation Characteristic in Microalloyed Low Carbon Bainite Cryogenic Pressure Vessel Steel, Trans. Ind. Inst. Met., 2016, 69, p 817–821

H. Bhadeshia, E. Keehan, L. Karlsson, and H.O. Andren, Coalesced Bainite, Trans. Ind. Inst. Met., 2006, 59, p 689–694

Z.M. Zhang, Q.W. Cai, W. Yu, X.L. Li, and L.D. Wang, Continuous Cooling Transformation Behavior and Kinetic Models of Transformations for an Ultra-Low Carbon Bainitic Steel, J Iron Steel Res. Int., 2012, 19, p 73–78

C. Capdevila, F.G. Caballero, C.G. Mateo, and C.G. Andres, The Role of Inclusions and Austenite Grain Size on Intragranular Nucleation of Ferrite in Medium Carbon Microalloyed Steels, Mater. Trans., 2004, 45, p 2678–2685

S.R. Dey, E. Bouzy, and A. Hazotte, Intragranular Nucleation Sites of Massive γ Grains in a TiAl-Based Alloy, Scr. Mater., 2007, 57, p 365–368

K.T. Park, S.W. Hwang, J.H. Ji, and C.H. Lee, Inclusions Nucleating Intragranular Polygonal Ferrite and Acicular Ferrite in Low Alloyed Carbon Manganese Steel Welds, Met. Mater. Int., 2011, 17, p 349–356

G. Krauss and S.W. Thompson, Ferritic Microstructure in Continuously Cooled Low and Ultralow Carbon Steels, ISIJ Int., 1995, 35, p 937–945

B. Jonson and J. Agren, On the Massive Transformation, Acta. Metall. Mater., 1990, 38, p 433–438

I.A. Rauf and J.D. Boyd, Microstructural Evolution During Thermomechanical Processing of a Ti-Nb Interstitial-Free Steel Just Below the Ar3 Temperature, Metall. Mater. Trans. A, 1997, 28, p 1437–1443

J.Y. Kang, S.C. Kim, J.O. Oh, H.N. Han, K.H. Oh, and H.C. Lee, Martensite in Interstitial-Free Steel Obtained by Ultra-High Pressure, Scripta Mater., 2012, 66, p 45–48

H.K.D.H. Bhadeshia, Diffusional Formation of Ferrite in Iron and Its Alloys, Prog. Mater. Sci., 1985, 29, p 321–386

P.S. Bandyopadhyay, S. Kundu, S.K. Ghosh, and S. Chatterjee, Structure and Properties of a Low-Carbon, Microalloyed, Ultra-High-Strength Steel, Metall. Mater. Trans A, 2011, 42, p 1051–1061

T. Zhang, Z. Li, S. Ma, S. Kou, and H. Jing, High Strength Steel (600–900 MPa) Deposited Metals: Microstructure and Mechanical Properties, Sci. Technol. Weld Join, 2016, 21, p 186–193

Z.T. Duan, Y.M. Li, F.X. Zhu, and H.Y. Zhang, Continues Cooling Transformation Behavior of Low Carbon Mn-Nb-B Steel, Adv. Mater. Res., 2011, 335, p 595

J. Wang, P.J. Van der Wolk, and S. Van der Zwaag, On the Influence of Alloying Elements on the Bainite Reaction in Low Alloy Steels During Continuous Cooling, J. Mater. Sci., 2000, 35, p 4393–4404

E.A. Wilson, γ → α Transformation in Fe, Fe-Ni, and Fe-Cr Alloys, Met. Sci., 1984, 18, p 471–484

M. Hillert and B. Sundman, A Solute-Drag Treatment of the Transition from Diffusion-Controlled to Diffusion Less Solidification, Acta Metall., 1977, 25, p 11–18

M. Zhang, L. Li, R.Y. Fu, D. Krizan, and B.C. De Cooman, Continuous Cooling Transformation Diagrams and Properties of Micro-alloyed TRIP Steels, Mater. Sci. Eng. A, 2006, 438–440, p 296–299

S. Chatterjee and S.K. Ghosh, Evolution of Microstructures and Mechanical Properties of Thermomechanically Processed Ultrahigh Strength Steels, Int. J. Metall. Eng., 2013, 2, p 92–99

N. Tsuji, Y. Matsubara, T. Sakai, and Y. Saito, Effect of Boron Addition on the Microstructure of Hot-Deformed Ti-Added Interstitial Free Steel, ISIJ Int., 1997, 37, p 797–806

S.I. Kim and Y. Lee, Influence of Cooling Rate and Boron Content on the Microstructure and Mechanical Properties of Hot-Rolled High Strength Interstitial-Free Steels, Met. Mater. Int., 2012, 18, p 735–744

Acknowledgments

The authors highly acknowledge the Institute Instrumentation Centre (IIC) and Department of Metallurgical and Materials Engineering, IIT Roorkee for providing the facilities and support to carry out the research work.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ghosh, S., Dasharath, S.M. & Mula, S. Simulation Kinetics of Austenitic Phase Transformation in Ti+Nb Stabilized IF and Microalloyed Steels. J. of Materi Eng and Perform 27, 2595–2608 (2018). https://doi.org/10.1007/s11665-018-3358-y

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-018-3358-y