Abstract

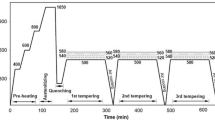

The microstructure and tempering response of Cr-V ledeburitic steel Vanadis 6 subjected to sub-zero treatment at − 196 °C for 4 h have been examined with reference to the same steel after conventional heat treatment. The obtained experimental results infer that sub-zero treatment significantly reduces the retained austenite amount, makes an overall refinement of microstructure, and induces a significant increase in the number and population density of small globular carbides with a size 100-500 nm. At low tempering temperatures, the transient M3C-carbides precipitated, whereas their number was enhanced by sub-zero treatment. The presence of chromium-based M7C3 precipitates was evidenced after tempering at the temperature of normal secondary hardening; this phase was detected along with the M3C. Tempering above 470 °C converts almost all the retained austenite in conventionally quenched specimens while the transformation of retained austenite is rather accelerated in sub-zero treated material. As a result of tempering, a decrease in the population density of small globular carbides was recorded; however, the number of these particles retained much higher in sub-zero treated steel. Elevated hardness of sub-zero treated steel can be referred to more completed martensitic transformation and enhanced number of small globular carbides; this state is retained up to a tempering temperature of around 500 °C in certain extent. Correspondingly, lower as-tempered hardness of sub-zero treated steel tempered above 500 °C is referred to much lower contribution of the transformation of retained austenite, and to an expectedly lower amount of precipitated alloy carbides.

Similar content being viewed by others

References

P. Jurči, Cr-V Ledeburitic Cold-Work Tool Steels, Mater. Technol., 2011, 45, p 383–394

D. Das, A.K. Dutta, and K.K. Ray, Sub-Zero Treatments of AISI, D2 Steel: Part I. Microstructure and Hardness, Mater. Sci. Eng., 2010, A527, p 2182–2193

D. Das and K.K. Ray, Structure-Property Correlation of Sub-Zero Treated AISI, D2 Steel, Mater. Sci. Eng. A, 2012, 541, p 45–60

D.N. Collins, Deep Cryogenic Treatment of Tool Steels—A Review, Heat Treat. Met., 1996, 2, p 40–42

K. Amini, A. Akhbarizadeh, and S. Javadpour, Investigating the Effect of Holding Duration on the Microstructure of 1.2080 Tool Steel During the Deep Cryogenic Treatment, Vacuum, 2012, 86, p 1534–1540

A. Akhbarizadeh, M.A. Golozar, A. Shafeie, and M. Kholghy, Effects of Austenitizing Time on Wear Behaviour of D6 Tool Steel After Deep Cryogenic Treatment, J. Iron Steel Res., 2009, 16(6), p 29–32

A. Akhbarizadeh, S. Javadpour, K. Amini, and A.H. Yaghtin, Investigating the Effect of Ball Milling During the Deep Cryogenic Heat Treatment of the 1.2080 Tool Steel, Vacuum, 2013, 90, p 70–74

A.I. Tyshchenko, W. Theisen, A. Oppenkowski, S. Siebert, O.N. Razumov, A.P. Skoblik, V.A. Sirosh, J.N. Petrov, and V.G. Gavriljuk, Low-Temperature Martensitic Transformation and Deep Cryogenic Treatment of a Tool Steel, Mater. Sci. Eng. A, 2010, 527, p 7027–7039

P. Jurči, M. Dománková, L. Čaplovič, J. Ptačinová, J. Sobotová, P. Salabová, O. Prikner, B. Šuštaršič, and D. Jenko, Microstructure and Hardness of Sub-Zero Treated and No Tempered P/M Vanadis 6 Ledeburitic Tool Steel, Vacuum, 2015, 111, p 92–101

P. Jurči, J. Sobotová, P. Salabová, O. Prikner, B. Šuštaršič, and D. Jenko, Subzero Treatment of P/M Vanadis 6 Ledeburitic Tool Steel, Int. Heat Treatment Surf. Eng., 2013, 7, p 125–128

M. Villa, K. Pantleon, and M.A.J. Somers, Evolution of Compressive Strains in Retained Austenite During Sub-Zero Celsius Martensite Formation and Tempering, Acta Mater., 2014, 65, p 383–392

P.F. Stratton, Optimising Nano-Carbide Precipitation in Tool Steels, Mater. Sci. Eng., 2007, A449–451, p 809–812

M.J. Van Genderen, A. Boettger, R.J. Cernik, and E.J. Mittemeijer, Early Stages of Decomposition in Iron-Carbon and Iron-Nitrogen Martensites: Diffraction Analysis Using Synchrotron Radiation, Metall. Trans., 1993, 24A, p 1965–1973

M. Preciado and M. Pellizzari, Influence of Deep Cryogenic Treatment on the Thermal Decomposition of Fe-C Martensite, J. Mater. Sci., 2014, 49, p 8183–8191

P. Jurči, Sub-Zero Treatment of Cold Work Tool Steels—Metallurgical Background and the Effect on Microstructure and Properties, HTM J. Heat Treat. Mater., 2017, 72, p 62–68

V.G. Gavriljuk, W. Theisen, V.V. Sirosh, E.V. Polshin, A. Kortmann, G.S. Mogilny, Yu.N. Petrov, and Y.V. Tarusin, Low-Temperature Martensitic Transformation in Tool Steels in Relation to their Deep Cryogenic Treatment, Acta Mater., 2013, 61, p 1705–1715

V.G. Gavriljuk, V.V. Sirosh, Yu.N. Petrov, A.I. Tyshchenko, W. Theisen, and A. Kortmann, Carbide Precipitation During Tempering of a Tool Steel Subjected to Deep Cryogenic Treatment, Metall. Mater. Trans., 2014, 45A, p 2453–2465

D.N. Collins and J. Dormer, Deep Cryogenic Treatment of a D2 Cold-Work Tool Steel, Heat Treat. Met., 1997, 24, p 71–74

K. Amini, A. Akhbarizadeh, and S. Javadpour, Investigating the Effect of the Quench Environment on the Final Microstructure and Wear Behaviour of 1.2080 Tool Steel After Deep Cryogenic Heat Treatment, Mater. Des., 2013, 45, p 316–322

A. Akhbarizadeh, K. Amini, and S. Javadpour, Effect of Simultaneous Magnetic Field and Deep Cryogenic Heat Treatment on the Microstructure of 1.2080 Tool Steel, Mater. Des., 2012, 35, p 484–490

K. Amini, A. Akhbarizadeh, and S. Javadpour, Effect of Deep Cryogenic Treatment on the Formation of Nano-Sized Carbides and the Wear Behaviour of D2 Tool Steel, Int. J. Miner. Metall. Mater., 2012, 19, p 795–799

P. Jurči, M. Kusý, J. Ptačinová, V. Kuracina, and P. Priknerová, Long-Term Sub-Zero Treatment of P/M Vanadis 6 Ledeburitic Tool Steel—A Preliminary Study, Manuf. Technol., 2015, 15, p 41–47

H. Paydar, K. Amini, and A. Akhbarizadeh, Investigating the Effect of Deep Cryogenic Heat Treatment on the Wear Behaviour of 100Cr6 Alloy Steel, Kovove Mater., 2014, 52, p 163–169

H. Berns, Restaustenit in ledeburitischen Chromstählen und seine Umwandlung durch Kaltumformen, Tiefkühlen und Anlassen, HTM J. Heat Treat. Mater., 1974, 29, p 236–247 (In German)

D.N. Collins, Cryogenic Treatment of Tool Steels, Adv. Mater. Proc., 1998, 12, p 24–29

M. Pellizzari and A. Molinari. Deep cryogenic treatment of cold work tool steel, in Proc. of the 6th Int. Tooling Conf., Karlstad, Sweden, 10–13 Sept 2002, ed by J. Bergstrom, G. Fredriksson, M. Johansson, O. Kotik, F. Thuvander, Karlstad University, pp. 547–558

J. Sobotová, P. Jurči, and I. Dlouhý, The Effect of Subzero Treatment on Microstructure, Fracture toughness, and Wear Resistance of Vanadis 6 Tool Steel, Mater. Sci. Eng. A, 2016, 652, p 192–204

ASTM, E975-13: Standard Practice for X-Ray Determination of Retained Austenite in Steel with Near Random Crystallographic Orientation, ASTM Book of Standards, vol. 3.01, ASTM, West Conshohocken, 2004

A. Stojko, M.F. Hansen, J. Slycke, and M.A.J. Somers, Isothermal Martensite Formation at Sub-Zero Temperatures, J. ASTM Int., 2011, 8, p 1–9

L. Cheng, C.M. Brakman, B.M. Korevaar, and E.J. Mittemeijer, The Tempering of Iron-Carbon Martensite; Dilatometric and Calorimetric Analysis, Metall. Trans., 1988, 19A, p 2415–2426

F. Meng, K. Tagashira, R. Azuma, and H. Sohma, Role of Eta-carbide Precipitation’s in the Wear Resistance Improvements of Fe-12Cr-Mo-V-1.4C Tool Steel by Cryogenic Treatment, ISIJ Int., 1994, 34, p 205–210

M. Pasak, R. Cicka, P. Bilek, P. Jurci, and L. Caplovic, Study of Phase Transformations in Cr-V Tool Steel, Mater. Technol., 2014, 48, p 693–696

T. Nykiel and T. Hryniewicz, Transformations of Carbides During Tempering of D3 Tool Steel, J. Mater. Eng. Perform., 2014, 23, p 2050–2054

A. Kulmburg, E. Putzgruber, F. Korntheurer, and E. Kaiser, Beitrag zum Tiefkuehlen von Schnellarbeitsstaehlen, HTM, 1992, 47, p 318–323 (In German)

A. Akhbarizadeh and S. Javadpour, Investigating the Effect of As-Quenched Vacancies in the Final Microstructure of 1.2080 Tool Steel During the Deep Cryogenic Heat Treatment, Mater. Lett., 2013, 93, p 247–250

P.F. da Silva Farina, A.B. Farina, C.A. Barbosa and H. Goldenstein. The effects of cryogenic and stress relief treatments in the temper carbides precipitation of an AISI D2 tool steel, in Proc. of the 9th Int. Tooling Conf., Leoben, Austria, 11–14 Sept 2012, ed by Leitner, H. Montanuniversitat Leoben, pp 42–50

P. Bílek, J. Sobotová, and P. Jurči, Evaluation of the Microstructural Changes in Cr-V Ledeburitic Tool Steel Depending on the Austenitization Temperature, Mater. Technol., 2011, 45, p 489–493

Acknowledgments

The authors acknowledge that the paper is a result of experiments realized within the Project VEGA 1/0735/14. In addition, this publication is the result of the Project implementation “Centre for Development and Application of Advanced Diagnostic Methods in Processing of Metallic and Non-Metallic Materials—APRODIMET”, ITMS: 26220120014, supported by the Research & Development Operational Programme funded by the ERDF.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Jurči, P., Dománková, M., Ptačinová, J. et al. Investigation of the Microstructural Changes and Hardness Variations of Sub-Zero Treated Cr-V Ledeburitic Tool Steel Due to the Tempering Treatment. J. of Materi Eng and Perform 27, 1514–1529 (2018). https://doi.org/10.1007/s11665-018-3261-6

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-018-3261-6