Abstract

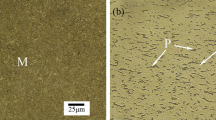

22MnB5 hot stamping steels are gradually being used in tailor-welded blank applications. In this experiment, 1-mm-thick Al-Si coated and de-coated 22MnB5 steels were laser-welded and then hot-stamped. The chemical compositions, solidification process, microstructure and mechanical properties were investigated to reveal the effect of Al-Si coating and heat treatment. In the welded condition, the coated joints had an Al content of approximately 2.5 wt.% in the fusion zone and the de-coated joints had 0.5 wt.% Al. The aluminum promoted the δ-ferrite formation as the skeletal structure during solidification. In the high-aluminum weld, the microstructure consisted of martensite and long and band-like δ-ferrite. Meanwhile, the low-aluminum weld was full of lath martensite. After the hot stamping process, the δ-ferrite fraction increased from 10 to 24% in the coated joints and the lath martensite became finer in the de-coated joints. The tensile strengths of the coated joints or de-coated joints were similar to that before hot stamping, but the strength of the coated joints was reduced heavily after hot stamping compared to the de-coated joints and base material. The effect of δ-ferrite on the tensile properties became stronger when the fusion zone was soft and deformed first in the hot-stamped specimens. The coated weld showed a brittle fracture surface with many cleavage planes, and the de-coated weld showed a ductile fracture surface with many dimples in hot-stamped conditions.

Similar content being viewed by others

References

T. Senuma, Physical Metallurgy of Modern High Strength Steel Sheets, ISIJ Int., 2001, 41(6), p 520–532

H. Karbasian and A.E. Tekkaya, A Review on Hot Stamping, J. Mater. Process. Technol., 2010, 210(15), p 2103–2118. https://doi.org/10.1016/j.jmatprotec.2010.07.019

D.W. Fan and B.C. De Cooman, State-of-the-Knowledge on Coating Systems for Hot Stamped Parts, Steel Res. Int., 2012, 83(5), p 412–433

R.J. Pallett and R.J. Lark, The Use of Tailored Blanks in the Manufacture of Construction Components, J. Mater. Process. Technol., 2001, 117(1–2), p 249–254

R.S. Sharma and P. Molian, Yb:YAG Laser Welding of TRIP780 Steel with Dual Phase and Mild Steels for Use in Tailor Welded Blanks, Mater. Des., 2009, 30(10), p 4146–4155. https://doi.org/10.1016/j.matdes.2009.04.033

Z. Gu, S. Yu, L. Han, X. Li, and H. Xu, Influence of Welding Speed on Microstructures and Properties of Ultra-High Strength Steel Sheets in Laser Welding, ISIJ Int., 2012, 52(3), p 483–487

A. Pic, D. Múnera, L. Cretteur, F. Schmit, and F. Pinard, Innovative Hot-Stamped Laser Welded Blank Solutions, Stahl Undsen, 2009, 128(8), p 59–66

C. Kim, M.J. Kang, and Y.D. Park, Laser Welding of Al-Si Coated Hot Stamping Steel, Procedia Eng., 2011, 10, p 2226–2231. https://doi.org/10.1016/j.proeng.2011.04.368

W. Ehling, L. Cretteur, A. Pic, R. Viestraete, and Q. Yin, Development of a Laser Decoating Process for Fully Functional Al-Si Coated Press Hardened Steel Laser Welded Blank Solutions, Proceedings of 5th International WLT-Conference on Lasers in Manufacturing, Munich, Germany (AT-Fachverlag GmbH, Stuttgart), 2009, p. 409–416.

R. Vierstraete, W. Ethling, F. Pinard, L. Cretteur, A. Pic, and Q. Yin, Laser Ablation for Hardening Laser Welded Steel Blanks, Ind. Laser Solut., 2010, 25(2), p 6

T. Flehmig, J. Gorschluter, and S. Wischmann, Method and Device for Mechanically Removing Coatings from Coated Blanks Using a Press and Scraping Knife, (Germany), US patent, 20140060281A1, 2014.

T. Flehmig, D. Scheuvens, and L. Homig, Device and Method for Partial Decoating And/or Machining of Material from a Workpiece, (Germany), US patent, 20150239053A1, 2015.

M. Kang, C. Kim, and S.M. Bae, Laser Tailor-Welded Blanks for Hot-Press-Forming Steel with Arc Pretreatment, Int. J. Autom. Technol., 2015, 16(2), p 279–283. https://doi.org/10.1007/s12239

M. Kang and C. Kim, Laser Welding for Hot-Stamped Tailor-Welded Blanks with High-Strength Steel/High-Energy Absorption Steel, J. Laser Appl., 2014, 26(3), p 32007. https://doi.org/10.2351/1.4881279

M. Kang, Y.M. Kim, and C. Kim, Effect of Heating Parameters on Laser Welded Tailored Blanks of Hot Press Forming Steel, J. Mater. Process. Technol., 2015, https://doi.org/10.1016/j.jmatprotec.2015.06.028

M. Windmann, A. Röttger, and W. Theisen, Formation of Intermetallic Phases in Al-Coated Hot-Stamped 22MnB5 Sheets in Terms of Coating Thickness and Si Content, Surf. Coat. Technol., 2014, 246, p 17–25

P. Mayr, T.A. Palmer, J.W. Elmer, E.D. Specht, and S.M. Allen, Formation of Delta Ferrite in 9 Wt Pct Cr Steel Investigated by in-Situ X-Ray Diffraction Using Synchrotron Radiation, Metall. Mater. Trans. A Phys. Metall. Mater. Sci., 2010, 41(10), p 2462–2465

S.H. Kim, H.K. Moon, T. Kang, and C.S. Lee, Dissolution Kinetics of Delta Ferrite in AISI, 304 Stainless Steel Produced by Strip Casting Process, Mater. Sci. Eng. A, 2003, 356(1–2), p 390–398

G. Lothongkum, E. Viyanit, and P. Bhandhubanyong, Study on the Effects of Pulsed TIG Welding Parameters on Delta-Ferrite Content, Shape Factor and Bead Quality in Orbital Welding of AISI, 316L Stainless Steel Plate, J. Mater. Process. Technol., 2001, 110(2), p 233–238

A. De, C.A. Walsh, S.K. Maiti, and H.K.D.H. Bhadeshia, Prediction of Cooling Rate and Microstructure in Laser Spot Welds, Sci. Technol. Weld. Join., 2003, 8(6), p 391–399

X. Wang, H. Li, Z. Liu, H. Liu, G. Wang, Z. Luo, F. Zhan, S. Chen, and L. Lyu, Effect of Cooling Rate on Bending Behavior of 6.5 wt.% Si Electrical Steel Thin Sheets Fabricated by Strip Casting and Rolling, Mater. Charact., 2016, 111, p 67–74. https://doi.org/10.1016/j.matchar.2015.11.008

S.S. Babu, J.W. Elmer, J.M. Vitek, and S.A. David, Time-Resolved X-Ray Diffraction Investigation of Primary Weld Solidification in Fe-C-Al-Mn Steel Welds, Acta Mater., 2002, 50(19), p 4763–4781

S.S. Babu, J.M. Vitek, J.W. Elmer, T.A. Palmer, and S.A. David, “Nonequilibrium Phase Selection During Weld Solidification of Fe-C-Mn-Al,” TMS (The minerals, Metals & Materials Society), 2004, p 5.

S. Katayama and A. Matsunawa, Solidification Microstructure of Laser Welded Stainless Steels, Proceedings of Material Processing Symposium; Laser Institute of America. ICALEO, 1984, p 60–67.

J.W. Elmer, S.M. Allen, and T.W. Eagar, Microstructural Development during Solidification of Stainless Steel Alloys, Metall. Trans. A, 1989, 20(October), p 2117–2131

C.Y. Lee and Y.K. Lee, The Solidification Mode of Fe-Mn-Al-C Lightweight Steel, JOM, 2014, 66(9), p 1794–1799. https://doi.org/10.1007/s11837-014-1000-5

L. Schafer, Influence of Delta Ferrite and Dendritic Carbides on the Impact and Tensile Properties of a Martensitic Chromium Steel, J. Nucl. Mater., 1998, 263, p 1336–1339

P. Wang, S.P. Lu, N.M. Xiao, D.Z. Li, and Y.Y. Li, Effect of Delta Ferrite on Impact Properties of Low Carbon 13Cr-4Ni Martensitic Stainless Steel, Mater. Sci. Eng. A, 2010, 527(13–14), p 3210–3216. https://doi.org/10.1016/j.msea.2010.01.085

M. Kang, C. Kim, and J. Lee, Weld Strength of Laser-Welded Hot-Press-Forming Steel, J. Laser Appl., 2012, 24(2), p 22004

Acknowledgments

This work received financial support from Baoshan Iron & Steel Co., Ltd. It was also supported by the Natural Science Foundation (NSF, Grant No. 51705318). This work was also supported by the Ministry of Industry and Information Technology of China under the project of LNG shipbuilding.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lin, W., Li, F., Wu, D. et al. Effect of Al-Si Coating on Weld Microstructure and Properties of 22MnB5 Steel Joints for Hot Stamping. J. of Materi Eng and Perform 27, 1825–1836 (2018). https://doi.org/10.1007/s11665-018-3259-0

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-018-3259-0