Abstract

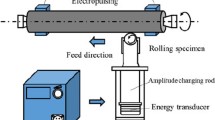

The effect of electropulsing-assisted ultrasonic nanocrystalline surface modification (EP-UNSM) on surface mechanical properties and microstructure of Ti-6Al-4V alloy is investigated. Compared to conventional ultrasonic nanocrystalline surface modification (UNSM), EP-UNSM can effectively facilitate surface roughness and morphology, leading to excellent surface roughness (reduced from Ra 0.918 to Ra 0.028 μm by UNSM and Ra 0.019 μm by EP-UNSM) and smoother morphology with less cracks and defects. Surface friction coefficients are enhanced, resulting in lower and smoother friction coefficients. In addition, the surface-strengthened layer and ultra-refined grains are significantly enhanced with more severe plastic deformation and a greater surface hardness (a maximum hardness value of 407 HV and an effective depth of 550 μm, in comparison with the maximum hardness value of 364 HV and effective depth of 300 μm obtained by conventional UNSM). Remarkable enhancement of surface mechanical properties can be attributed to the refined gradient microstructure and the enhanced severe plastic deformation layer induced by coupling the effects of UNSM and electropulsing. The accelerated dislocation mobility and atom diffusion caused by the thermal and athermal effects of electropulsing treatment may be the primary intrinsic reasons for these improvements.

Similar content being viewed by others

References

D.S. Milovanović, B.B. Radak, B.M. Gaković, D. Batani, M.D. Momčilović, and M.S. Trtica, Surface Morphology Modifications of Titanium Based Implant Induced by 40 picosecond laser Pulses at 266 nm, J. Alloys Compd., 2010, 501(1), p 89–92

M. Masmoudi, M. Assoul, M. Wery, R. Abdelhedi, F.E. Halouani, and G. Monteil, Wear Behaviour of Nitric Acid Passivated cp Ti and Ti6Al4V, J. Alloys Compd., 2009, 478(1–2), p 726–730

C. Ye, A. Telang, A.S. Gill, S. Suslov, Y. Idell, Z. Kai, J.M.K. Wiezorek, Z. Zhou, D. Qian, and S.R. Mannava, Gradient Nanostructure and Residual Stresses Induced by Ultrasonic Nano-crystal SURFACE Modification in 304 Austenitic Stainless Steel for High Strength and High Ductility, Mater. Sci. Eng. A, 2014, 613(11–12), p 274–288

A.V. Panin, M.S. Kazachenok, A.I. Kozelskaya, R.R. Hairullin, and E.A. Sinyakova, Mechanisms of Surface Roughening of Commercial Purity Titanium During Ultrasonic Impact Treatment, Mater. Sci. Eng. A, 2015, 647, p 43–50

A. Amanov, Y.S. Pyun, and S. Sasaki, Effects of Ultrasonic Nanocrystalline Surface Modification (UNSM) Technique on the Tribological Behavior of Sintered Cu-Based Alloy, Tribol. Int., 2014, 72(4), p 187–197

V. Singh and M. Marya, Surface Modification of Oilfield Alloys by Ultrasonic Impact Peening: UNS N07718, N07716, G41400, and S17400, J. Mater. Eng. Perform., 2016, 25(1), p 338–347

X.J. Cao, Y.S. Pyoun, and R. Murakami, Fatigue Properties of a S45C Steel Subjected to Ultrasonic Nanocrystal Surface Modification, Appl. Surf. Sci., 2010, 256(21), p 6297–6303

A. Amanov, I.S. Cho, and Y.S. Pyun, Microstructural Evolution and Surface Properties of Nanostructured Cu-Based Alloy by Ultrasonic Nanocrystalline Surface Modification Technique, Appl. Surf. Sci., 2016, 388, p 185–195

J. Yu, G. Gou, L. Zhang, W. Zhang, H. Chen, and Y.P. Yang, Ultrasonic Impact Treatment to Improve Stress Corrosion Cracking Resistance of Welded Joints of Aluminum Alloy, J. Mater. Eng. Perform., 2016, 25(7), p 3046–3056

B. Wu, P. Wang, Y.S. Pyoun, J. Zhang, and R.I. Murakami, Effect of Ultrasonic Nanocrystal Surface Modification on the Fatigue Behaviors of Plasma-Nitrided S45C Steel, Surf. Coat. Technol., 2012, 213(12), p 271–277

A. Cherif, Y. Pyoun, and B. Scholtes, Effects of Ultrasonic Nanocrystal Surface Modification (UNSM) on Residual Stress State and Fatigue Strength of AISI, 304, J. Mater. Eng. Perform., 2010, 19(2), p 282–286

A. Amanov, B. Urmanov, T. Amanov, and Y.S. Pyun, Strengthening of Ti-6Al-4V Alloy by High Temperature Ultrasonic Nanocrystal Surface Modification Technique, Mater. Lett., 2017, 196, p 198–201

I.S. Cho, A. Amanov, D.H. Kwak, B.J. Jeong, and I.G. Park, The Influence of Surface Modification Techniques on Fretting Wear of Al-Si Alloy Prepared by Gravity Die Casting, Mater. Design, 2015, 65(65), p 401–409

A. Karimi and S. Amini, Steel 7225 Surface Ultrafine Structure and Improvement of Its Mechanical Properties Using Surface Nanocrystallization Technology by Ultrasonic Impact, Int. J. Adv. Manuf. Technol., 2016, 83(5–8), p 1127–1134

H. Wang, G. Song, and G. Tang, Enhanced Surface Properties of Austenitic Stainless Steel by Electropulsing-Assisted Ultrasonic Surface Rolling Process, Surf. Coat. Technol., 2015, 282, p 149–154

X. Yang, J. Zhou, and X. Ling, Study on Plastic Damage of AISI, 304 Stainless Steel Induced by Ultrasonic Impact Treatment, Mater. Design, 2012, 36, p 477–481

R. Zhu, G. Tang, S. Shi, and M. Fu, Effect of Electroplastic Rolling on Deformability and Oxidation of NiTiNb Shape Memory Alloy, J. Mater. Process. Technol., 2013, 213(1), p 30–35

Y. Jiang, L. Guan, G. Tang, C. Shek, and Z. Zhang, Influence of Electropulsing Treatment on Microstructure and Mechanical Properties of Cold-Rolled Mg-9Al-1Zn Alloy Strip, Mater. Sci. Eng. A, 2011, 528(16), p 5627–5635

X. Li, F. Wang, X. Li, G. Tang, and J. Zhu, Improvement of Formability of Mg-3Al-1Zn Alloy Strip by Electroplastic-Differential Speed Rolling, Mater. Sci. Eng. A, 2014, 618, p 500–504

J. Kuang, X. Li, R. Zhang, Y. Ye, A.A. Luo, and G. Tang, Enhanced rollability of Mg 3Al 1Zn Alloy by Pulsed Electric Current: A Comparative Study, Mater. Design, 2016, 100, p 204–216

Y. Jiang, G. Tang, C. Shek, and Y. Zhu, Effect of Electropulsing Treatment on Microstructure and Tensile Fracture Behavior of Aged Mg-9Al-1Zn Alloy Strip, Appl. Phys. A, 2009, 97(3), p 607–615

Y. Jiang, G. Tang, C. Shek, Y. Zhu, L. Guan, S. Wang, and Z. Xu, Improved Ductility of Aged Mg-9Al-1Zn Alloy Strip by Electropulsing Treatment, J. Mater. Res., 2009, 24(5), p 1810–1814

R. Qin and S. Su, Thermodynamics of Crack Healing Under Electropulsing, J. Mater. Res., 2002, 17(8), p 2048–2052

A. Hosoi, T. Nagahama, and Y. Ju, Fatigue Crack Healing by a Controlled High Density Electric Current Field, Mater. Sci. Eng. A, 2012, 533(1), p 38–42

J. Kuang, X. Li, X. Ye, J. Tang, H. Liu, J. Wang, and G. Tang, Microstructure and Texture Evolution of Magnesium Alloys During Electropulse Treatment, Metall. Mater. Trans. A, 2015, 46(4), p 1789–1804

J. Kuang, X. Du, X. Li, Y. Yang, A.A. Luo, and G. Tang, Athermal influence of Pulsed Electric Current on the Twinning Behavior of Mg-3Al-1Zn Alloy During Rolling, Scr. Mater., 2016, 114, p 151–155

A. Rahnama and R.S. Qin, The Effect of Electropulsing on the Interlamellar Spacing and Mechanical Properties of a Hot-Rolled 0.14% Carbon Steel, Mater. Sci. Eng. A, 2015, 627, p 145–152

L. Guan, G. Tang, Y. Jiang, and P.K. Chu, Texture Evolution in Cold-Rolled AZ31 Magnesium Alloy During Electropulsing Treatment, J. Alloys Compd., 2009, 487(1–2), p 309–313

R.F. Zhu, G.Y. Tang, S.Q. Shi, M.W. Fu, and V.E. Gromov, Effect of Electropulsing Treatment on the Microstructure and Superelasticity of TiNi Alloy, Appl. Phys. A, 2013, 111(4), p 1195–1201

V.E. Gromov, Y.F. Ivanov, V.V. Sizov, S.V. Vorob’Ev, and S.V. Konovalov, Increase in the Fatigue Durability of Stainless Steel by Electron-Beam Surface Treatment, J. Surf. Investig. X-ray Synchrotron Neutron Tech, 2013, 7(1), p 94–98

R.S. Qin, A. Rahnama, W.J. Lu, X.F. Zhang, and B. Elliottbowman, Electropulsed Steels, Mater. Sci. Tech-Lond, 2014, 30(9), p 1040

H. Wang, G. Song, and G. Tang, Evolution of Surface Mechanical Properties and Microstructure of Ti 6Al 4V Alloy Induced by Electropulsing-Assisted Ultrasonic Surface Rolling Process, J. Alloys Compd., 2016, 681, p 146–156

H. Wang, G. Song, and G. Tang, Effect of Electropulsing on Surface Mechanical Properties and Microstructure of AISI, 304 Stainless Steel During Ultrasonic Surface Rolling Process, Mater. Sci. Eng. A, 2016, 662, p 456–467

Y. Fu, N.L. Loh, A.W. Batchelor, D. Liu, X. Zhu, J. He, and K. Xu, Improvement in Fretting Wear and Fatigue Resistance of Ti-6Al-4V by Application of Several Surface Treatments and Coatings, Surf. Coat. Technol., 1998, 106, p 193–197

G. Li, S.G. Qu, Y.X. Pan, and X.Q. Li, Effects of the Different Frequencies and Loads of Ultrasonic Surface Rolling on Surface Mechanical Properties and Fretting Wear Resistance of HIP Ti-6Al-4V Alloy, Appl. Surf. Sci., 2016, 389, p 324–334

A. Amanov, J.H. Kim, Y.S. Pyun, T. Hirayama, and M. Hino, Wear Mechanisms of Silicon Carbide Subjected to Ultrasonic Nanocrystalline Surface Modification Technique, Wear, 2015, 332–333, p 891–899

D.H. Jeong, U. Erb, K.T. Aust, and G. Palumbo, The Relationship Between Hardness and Abrasive Wear Resistance of Electrodeposited Nanocrystalline Ni-P Coatings, Scr. Mater., 2003, 48, p 1067–1072

A. Amanov, I.S. Cho, D.E. Kim, and Y.S. Pyun, Fretting Wear and Friction Reduction of CP Titanium And Ti-6Al-4V Alloy by Ultrasonic Nanocrystalline Surface Modification, Surf. Coat. Technol., 2012, 207(21), p 135–142

Q. Xu, G. Tang, and Y. Jiang, Thermal and Electromigration Effects of Electropulsing on Dynamic Recrystallization in Mg-3Al-1Zn Alloy, Mater. Sci. Eng. A, 2011, 528(13–14), p 4431–4436

Y.H. Zhu, S. To, W.B. Lee, X.M. Liu, Y.B. Jiang, and G.Y. Tang, Effects of Dynamic Electropulsing on Microstructure and Elongation of a Zn-Al Alloy, Mater. Sci. Eng. A, 2009, 501(1), p 125–132

G. Tang, J. Zhang, M. Zheng, J. Zhang, W. Fang, and Q. Li, Experimental Study of Electroplastic Effect on Stainless Steel Wire 304L, Mater. Sci. Eng. A, 2000, 281(1–2), p 263–267

Acknowledgments

The authors wish to acknowledge the financial support from the Guangdong Science and Technology Plan Project (2014B090901029), the Shenzhen Development and Reform Commission Engineering Laboratory Project (Shenzhen development and Reform 2015-1033), the Shenzhen Science and Technology supporting Plan Project (GJHS20160331183313435) and the project funded by China Postdoctoral Science Foundation (No. 2017M620770).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ye, Y., Wang, H., Tang, G. et al. Effect of Electropulsing-Assisted Ultrasonic Nanocrystalline Surface Modification on the Surface Mechanical Properties and Microstructure of Ti-6Al-4V Alloy. J. of Materi Eng and Perform 27, 2394–2403 (2018). https://doi.org/10.1007/s11665-018-3248-3

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-018-3248-3