Abstract

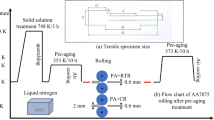

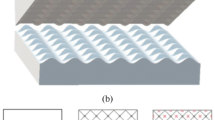

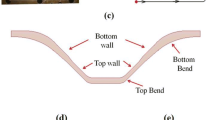

In this work, microstructure, mechanical properties and formability of cryorolled and annealed AA5083 alloy sheets have been characterized and a comparison has been made with cold rolled and annealed sheets. Five-millimeter-thick sheets of this alloy were cryorolled in multiple passes to a final thickness of 1 mm (80% reduction with a true strain of 1.6). Effect of annealing time and temperature on hardness has been studied, and it has been found that a short annealing at 275 °C for 15 min after cryorolling would yield a good combination of strength and ductility. Microstructural investigations showed that the cryorolled and short annealed samples possess bimodal grain structure which is responsible for better mechanical properties than cold rolled sheets. From the experimentally determined forming limit diagrams, the limit strains of cryorolled sheets have been found to be almost equal to conventional cold rolled and annealed sheets in all modes of deformation. No major differences have been found in strain distribution also. This work clearly demonstrates that cryorolling of AA5083 alloy sheets followed by a short annealing with bimodal grain structure can be used for sheet metal forming applications with higher strength and toughness than conventional sheets without any reduction in formability.

Similar content being viewed by others

References

I.J. Polmear, Light Alloys, Metallurgy of the Light Metals, 2nd ed., Edward Arnold, Melbourne, 1989, p 101–111

I.R. Dover and J.D. Embury, The Influence of Microstructural Features on the Formability of Aluminium Alloys, Mater. Forum, 1986, 9(4), p 188–201

J. Yan, N.M. Heckman, L. Velasco, and A.M. Hodge, Improve Sensitization and Corrosion Resistance of an Al-Mg Alloy by Optimization of Grain Boundaries, Sci. Rep., 2016, https://doi.org/10.1038/srep26870

H.L. Yu, C. Lu, A.K. Tieu, H.J. Li, A. Godbole, and S.H. Zhang, Special Rolling Techniques for Improvement of Mechanical Properties of Ultrafine-Grained Metal Sheets: A Review, Adv. Eng. Mater., 2015, 18, p 754–769

Y. Wang, M. Chen, F. Zhou, and E. Ma, High Tensile Ductility in a Nanostructured Metal, Nature, 2002, 419(6910), p 912–915

D. Singh, P. Nageswararao, and R. Jayaganthan, Microstructural Studies of Al 5083 Alloy Deformed through Cryorolling, Adv. Mater. Res., 2012, 585, p 376–380. https://doi.org/10.4028/www.scientific.net/AMR.585.376

S. Cheng, Y.H. Zhao, Y.T. Zhu, and E. Ma, Optimizing the Strength and Ductility of Fine Structured 2024 Al Alloy by Nano-Precipitation, Acta Mater., 2007, 55(17), p 5822–5832

D.K.K. Yang, P. Cizek, D. Fabijanic, J.T.T. Wang, and P.D.D. Hodgson, Work Hardening in Ultrafine-Grained Titanium: Multilayering and Grading, Acta Mater., 2013, 61(8), p 2840–2852

A. Dhal, S.K. Panigrahi, and M.S. Shunmugam, Insight into the Microstructural Evolution During Cryo-Severe Plastic Deformation and Post-Deformation Annealing of Aluminum and Its Alloys, J. Alloy. Compd., 2017, 726, p 1205–1219

S.K. Panigrahi and R. Jayaganthan, Influence of Solutes and Second Phase Particles on Work Hardening Behavior of Al 6063 Alloy Processed by Cryorolling, Mater. Sci. Eng., A, 2011, 528(7–8), p 3147–3160

P.N. Rao, D. Singh, and R. Jayaganthan, Effect of Annealing on Microstructure and Mechanical Properties of Al 6061 Alloy Processed by Cryorolling, Mater. Sci. Technol., 2013, 29(1), p 76–82. https://doi.org/10.1179/1743284712Y.0000000041

S.K. Panigrahi and R. Jayaganthan, Effect of Annealing on Precipitation, Microstructural Stability, and Mechanical Properties of Cryorolled Al 6063 Alloy, J. Mater. Sci., 2010, 45(20), p 5624–5636

L.W. Quan, W.N. Mu, L. Kang, X. Ma, P. Han, and M.L. Huang, The Effect of Cryorolling on the Microstructure of Al-Cu-Mg Alloy, Mater. Sci. Forum, 2016, 877, p 188–193. https://doi.org/10.4028/www.scientific.net/MSF.877.188

D. Singh, P.N. Rao, and R. Jayaganthan, Effect of Deformation Temperature on Mechanical Properties of Ultrafine Grained Al-Mg Alloys Processed by Rolling, Mater. Des., 2013, 50, p 646–655. https://doi.org/10.1016/j.matdes.2013.02.068

S.K. Panigrahi and R. Jayaganthan, A Study on the Mechanical Properties of Cryorolled Al-Mg-Si Alloy, Mater. Sci. Eng., A, 2008, 480(1–2), p 299–305

H. Yu, A.K. Tieu, C. Lu, X. Liu, M. Liu, A. Godbole, C. Kong, and Q. Qin, A New Insight into Ductile Fracture of Ultrafine-Grained Al-Mg Alloys, Sci. Rep., 2015, 5, p 9568

H. Yu, H. Wang, C. Lu, A.K. Tieu, H. Li, A. Godbole, X. Liu, C. Kong, and X. Zhao, Microstructure Evolution of Accumulative Roll Bonding Processed Pure Aluminum during Cryorolling, J. Mater. Res., 2016, 31(6), p 797–805

Y.B. Lee, D.H. Shin, K.-T. Park, and W.J. Nam, Effect of Annealing Temperature on Microstructures and Mechanical Properties of a 5083 Al Alloy Deformed at Cryogenic Temperature, Scripta Mater., 2004, 51(4), p 355–359

D. Singh, P. Nageswara Rao, and R. Jayaganthan, Microstructures and Impact Toughness Behavior of Al 5083 Alloy Processed by Cryorolling and Afterwards Annealing, Int. J. Miner. Metall. Mater., 2013, 20(8), p 759–769

T. Shanmugasundaram, B.S. Murty, and V. Subramanya Sarma, Development of Ultrafine Grained High Strength Al-Cu Alloy by Cryorolling, Scripta Mater., 2006, 54(12), p 2013–2017

P.N. Rao, S.K. Panigrahi, and R. Jayaganthan, Effect of Annealing and Aging Treatment on Mechanical Properties of Ultrafine Grained Al 6061 Alloy, Mater. Sci. Technol., 2010, 26(3), p 371–374. https://doi.org/10.1179/174328409X443227

P.N. Rao, A. Kaurwar, D. Singh, and R. Jayaganthan, Enhancement in Strength and Ductility of Al-Mg-Si Alloy by Cryorolling Followed by Warm Rolling, Proc. Eng., 2014, 75, p 123–128

P. Das, R. Jayaganthan, and I.V. Singh, Tensile and Impact-Toughness Behaviour of Cryorolled Al 7075 Alloy, Mater. Des., 2011, 32, p 1298–1305

Y. Shi, M. Li, D. Guo, T. Ma, Z. Zhang, X. Li, G. Zhang, and X. Zhang, Extraordinary Toughening by Cryorolling in Zr, Adv. Eng. Mater., 2014, 16(2), p 167–170

B.B. He, B. Hu, H.W. Yen, G.J. Cheng, Z.K. Wang, H.W. Luo, and M.X. Huang, High Dislocation Density-Induced Large Ductility in Deformed and Partitioned Steels, Science, 2017, 357(6355), p 1029–1032

I.A. Ovid’Ko and T.G. Langdon, Enhanced Ductility of Nanocrystalline and Ultrafine-Grained Metals, Rev. Adv. Mater. Sci., 2012, 30(2), p 103–111

R.O. Ritchie, The Conflicts between Strength and Toughness, Nat. Mater. Nat. Res., 2011, 10(11), p 817–822

Y. Wei, Y. Li, L. Zhu, Y. Liu, X. Lei, G. Wang, Y. Wu, Z. Mi, J. Liu, and H. Wang, Evading the Strength–ductility Trade-off Dilemma in Steel through Gradient Hierarchical Nanotwins, Nat. Commun., 2014, 5, p 3580

L. Lu, M.L. Sui, and K. Lu, Superplastic Extensibility of Nanocrystalline Copper at Room Temperature, Science, 2000, 287(5457), p 1463–1466

K. Lu, Making Strong Nanomaterials Ductile with Gradients, Science, 2014, 345(6203), p 1455–1456

V.A. Pozdnyakov, Ductility of Nanocrystalline Materials with a Bimodal Grain Structure, Tech. Phys. Lett., 2007, 33(12), p 1004–1006. https://doi.org/10.1134/s1063785007120061

M.S. Oskooie, H. Asgharzadeh, and H.S. Kim, Microstructure, Plastic Deformation and Strengthening Mechanisms of an Al–Mg–Si Alloy with a Bimodal Grain Structure, J. Alloy. Compd., 2015, 632, p 540–548

K. Krishna, S. Vigneshwaran, K.C. Sekhar, S.S.R. Akella, K. Sivaprasad, R. Narayanasamy, and K. Venkateswarlu, Mechanical Behavior and Void Coalescence Analysis of Cryorolled AA8090 Alloy, Int. J. Adv. Manuf. Technol., 2016, 93, p 1–7

N. Rangaraju, T. Raghuram, B.V. Krishna, K.P. Rao, and P. Venugopal, Effect of Cryo-Rolling and Annealing on Microstructure and Properties of Commercially Pure Aluminium, Mater. Sci. Eng., A, 2005, 398(1), p 246–251

S.H. Choi, J.H. Cho, K.H. Oh, F. Barlat, K. Chung, and J.W. Kwon, Prediction of Yield Surfaces of Textured Sheet Metals, Metall. Mater. Trans. A, 1999, 30(2), p 377–386

K.K. Mathur, P.R. Dawson, and U.F. Kocks, On Modeling Anisotropy in Deformation Processes Involving Textured Polycrystals with Distorted Grain Shape, Mech. Mater., 1990, 10(3), p 183–202

A.S. Taylor, M. Weiss, T. Hilditch, P.D. Hodgson, and N. Stanford, Cryo-Rolling and Formability of 2024 Aluminium, Mater. Sci. Forum, 2013, 765, p 434–438. https://doi.org/10.4028/www.scientific.net/MSF.765.434

K.C. Sekhar, R. Narayanasamy, and K. Velmanirajan, Experimental Investigations on Microstructure and Formability of Cryorolled AA 5052 Sheets, Mater. Des., 2014, 53, p 1064–1070

W.F. Hosford and R.M. Caddell, Metal Forming: Mechanics and Metallurgy, Cambridge University Press, New York, 2011, p 207–216

A.K. Ghosh and S.S. Hecker, Failure in Thin Sheets Stretched over Rigid Punches, Metall. Trans. A, 1975, 6(5), p 1065–1074. https://doi.org/10.1007/BF02661361

K. Nakazima, T. Kikuma, and K. Hasuka, Study on the Formability of Steel Sheets, Yawata Tech. Rep., 1968, 264, p 8517–8530

G.K. Williamson and W.H. Hall, X-Ray Line Broadening from Filed Aluminium and Wolfram, Acta Metall., 1953, 1(1), p 22–31

H. Adachi, Y. Miyajima, M. Sato, and N. Tsuji, Evaluation of Dislocation Density for 1100 Aluminum with Different Grain Size during Tensile Deformation by Using In-Situ X-Ray Diffraction Technique, Mater. Trans., 2015, 56(5), p 671–678

K.F. Zhang and H.-H. Yan, Deformation Behavior of Fine-Grained 5083 Al Alloy at Elevated Temperature, Trans. Nonferrous Metals Soc. China, 2009, 19, p s307–s311

A. Yilmaz, The Portevin–Le Chatelier Effect: A Review of Experimental Findings, Sci. Technol. Adv. Mater., 2011, 12(6), p 63001. https://doi.org/10.1088/1468-6996/12/6/063001

K. Krishna, K.C. Sekhar, R. Tejas, N.N. Krishna, K. Sivaprasad, R. Narayanasamy, and K. Venkateswarlu, Effect of Cryorolling on the Mechanical Properties of AA5083 Alloy and the Portevin–Le Chatelier Phenomenon, Mater. Des., 2015, 67, p 107–117

H. Ait-Amokhtar, C. Fressengeas, and K. Bouabdallah, On the Effects of the Mg Content on the Critical Strain for the Jerky Flow of Al-Mg Alloys, Mater. Sci. Eng., A, 2015, 631, p 209–213. https://doi.org/10.1016/j.msea.2015.02.055

L. Ziani, S. Boudrahem, H. Ait-Amokhtar, M. Mehenni, and B. Kedjar, Unstable Plastic Flow in the Al-2%Mg Alloy, Effect of Annealing Process, Mater. Sci. Eng., A, 2012, 536, p 239–243. https://doi.org/10.1016/j.msea.2012.01.004

H. Ait-Amokhtar and C. Fressengeas, Crossover from Continuous to Discontinuous Propagation in the Portevin–Le Chatelier Effect, Acta Mater., 2010, 58(4), p 1342–1349. https://doi.org/10.1016/j.actamat.2009.10.038

H. Dierke, F. Krawehl, S. Graff, S. Forest, J. Šachl, and H. Neuhäuser, Portevin–Le Chatelier Effect in Al-Mg Alloys: Influence of Obstacles - Experiments and Modelling, Comput. Mater. Sci., 2007, 39(1), p 106–112

P.C. Ma, D. Zhang, L.-Z. Zhuang, and J.-S. Zhang, Effect of Alloying Elements and Processing Parameters on the Portevin-Le Chatelier Effect of Aluminum-Magnesium Alloys, Int. J. Miner. Metall. Mater., 2015, 22(2), p 175–183

N.B.K. Babu, M.J. Davidson, and A. Neelakanteswara Rao, Investigation on the Influence of the Lubrication on the Formability of Dissimilar Tailor Welded Blanks, Trans. Indian Inst. Met., 2015, 68(4), p 529–534. https://doi.org/10.1007/s12666-014-0482-8

Acknowledgments

The authors acknowledge the help received from Prof. R. Jayaganthan, IIT Roorkee, Prof. I. Samjdar, IIT Bombay and Dr. S. Panigrahi, IIT Madras in characterization of the cold rolled and cryorolled samples.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Feyissa, F., Ravi Kumar, D. & Rao, P.N. Characterization of Microstructure, Mechanical Properties and Formability of Cryorolled AA5083 Alloy Sheets. J. of Materi Eng and Perform 27, 1614–1627 (2018). https://doi.org/10.1007/s11665-018-3243-8

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-018-3243-8