Abstract

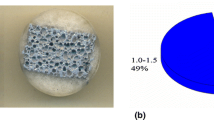

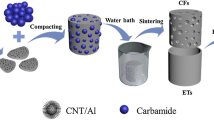

This study has examined proposed structures with mild steel-reinforced LM30 aluminum (Al) alloy having diversely unfilled and 10 wt.% SiCp composite foam-filled tubes for improving axial compression performance. This class of material has novel physical, mechanical, and electrical properties along with low density. In the present experiment, Al alloy foams were prepared by the melt route technique using metal hydride powder as a foaming agent. Crash energy phenomena for diverse unfilled and foam-filled in mild steel thin-wall tubes (triangular, square and hexagonal) were studied as well. Compression deformation investigation was conducted at strain rates of 0.001-0.1/s for evaluating specific energy absorption (SEA) under axial loading conditions. The results were examined to measure plateau stress, maximum densification strain, and deformation mechanism of the materials. Specific energy absorption and total energy absorption capacities of the unfilled and filled sections were determined from the compressive stress–strain curves, which were then compared with each other.

Similar content being viewed by others

References

J.M. Holdridge, V.N. Shankar, and G.F. Ulfarsson, The Crash Severity Impacts of Fixed Roadside Objects, J. Safety Res., 2005, 36(2), p 139–147

L. Guo and J. Yu, Dynamic Bending Response of Double Cylindrical Tubes Filled with Aluminum Foam, Int. J. Impact Eng, 2011, 238(2), p 85–94

M.M. Abedi, A. Niknejad, G.H. Liaghat, and M.Z. Nejad, Theoretical and Experimental Study on Empty and Foam-Filled Columns with Square and Rectangular Cross Section Under Axial Compression, Int. J. Mech. Sci., 2012, 65(1), p 134–146

A. Darvizeh, M. Darvizeh, R. Ansari, and A. Meshkinzar, Effect of Low Density, Low Strength Polyurethane Foam on The Energy Absorption Characteristics of Circumferentially Grooved Thick-Walled Circular Tubes, Thin Wall. Struct., 2013, 71, p 81–90

A.G. Hanssen, M. Langseth, and O.S. Hopperstad, Optimum Design for Energy Absorption of Square Aluminium Columns with Aluminium Foam Filler, Int. J. Mech. Sci., 2001, 43(1), p 153–176

M. Guden and H. Kavi, Quasi-Static Axial Compression Behaviour of Constraint Hexagonal and Square-Packed Empty and Aluminum Foam-Filled Aluminum Multi-Tubes, Thin Wall. Struct., 2006, 44(7), p 739–750

A.G. Hanssen, M. Langseth, and O.S. Hopperstad, The Static and Dynamic Crushing of Circular Aluminium Extrusions with Aluminium Foam Filler, Int. J. Impact Eng, 2000, 24(5), p 475–507

A.G. Hanssen, M. Langseth, and O.S. Hopperstad, Static and Dynamic Crushing of Square Aluminium Extrusions with Aluminium Foam Filler, Int. J. Impact Eng, 2000, 24(4), p 347–383

J.M. Babbage and P.K. Mallick, Static Axial Crush Performance of Unfilled and Foam-Filled Aluminium–Composite Hybrid Tubes, Compos. Struct., 2005, 70(2), p 177–184

S.R. Guillow, G. Lu, and R.H. Grzebieta, Quasi-Static Axial Compression of Thin-Walled Circular Aluminium Tubes, Int. J. Mech. Sci., 2001, 43, p 2103–2123

T.Y. Reddy and R.J. Wall, Axial Compression of Foam-Filled Thin-Walled Circular Tubes, Int. J. Impact Eng, 1988, 7, p 151–166

A.G. Mamalis, D.E. Manolakos, G.A. Demosthenous, and W. Johnson, Axial Plastic Collapse of Thin Bi-Material Tubes as Energy Dissipating Systems, Int. J. Impact Eng, 1991, 11, p 185–196

D.K. Rajak, L.A. Kumaraswamidhas, and S. Das, Investigation, and Characterization of Aluminium Alloy Foams with TiH2 as Foaming Agent, Mater. Sci. Technol., 2016, 32(13), p 1338–1345

L.A. Kumaraswamidhas, D.K. Rajak, and S. Das, An Investigation on the Axial Deformation Behaviour of Thin-Wall Unfilled and Filled the Tube with Aluminium Alloy (Al–Si7 Mg) Foam-Reinforced with SiC Particles, J. Mater. Eng. Perform., 2016, 25(8), p 3430–3438

D.K. Rajak, L.A. Kumaraswamidhas, and S. Das, An Energy Absorption Behaviour of Foam Filled Structures, Proc. Mater. Sci., 2014, 5, p 164–172

G.J. Davies and S. Zhen, Metallic Foams: Their Production, Properties and Applications, J. Mater. Sci., 1983, 18(7), p 1899–1911

L.J. Gibson, Metal Matrix Composite, Handbook, 3rd edn. Kelly Anthony, Zweben Carl, 2000, p 821

J. Banhart, Manufacturing Routes for Metallic Foams, J. Metal., 2000, 12, p 22–27

V. Gergely and T.W. Clyne, Drainage in Standing Liquid Metal Foams: Modelling and Experimental Observations, Acta Mater., 2004, 52, p 3047–3058

C. Korner and R.F. Singer, Processing of Metal Foams—Challenges and Opportunities, Adv. Eng. Mater., 2000, 2(4), p 159–165

I. Duarte, J. Mascarenhas, A. Ferreira, and J. Banhart, The Evolution of Morphology and Kinetics During the Foaming Process of Aluminium, Key Eng. Mater., 2002, 2320–232, p 96–101

A.E. Simone and L.J. Gibson, Aluminium Foams Produced by Liquid-State Processes, Acta Mater., 1998, 46(9), p 3109–3123

Y. Miyoshi, M. Itoh, S. Akiyama, and A. Kitahara, ALPORAS Aluminium Foam: Production Process, Properties, and Applications, Adv. Eng. Mater., 2002, 2(4), p 179–183

W. Deqing and S. Ziyuan, Effect of Ceramic Particles on Cell Size and a Wall Thickness of Aluminium Foam, Mater. Sci. Eng., 2003, 361, p 45–49

B. Kritzt, U. Martin, U. Mosler, Handbook of Cellular Metals: Production, Processing, Application, 2002, p 130

O. Prakash, H. Sang, and J.D. Embury, Structure and Properties of the Al–SiC Foam, Mater. Sci. Eng., A, 1995, 199, p 195–203

S.W. Ip, Y. Wang, and J.D. Toguri, Aluminium Foam Stabilization by Solid Particles, Can. Matall. Q., 1999, 38(1), p 81–92

A. Haibel, A. Rack, and J. Banhart, Why are Metal Foams Stable, Appl. Phys. Lett., 2006, 89(15), p 154102

D.K. Rajak, L.A. Kumaraswamidhas, S. Das, and S.S. Kumaran, Characterization and Analysis of Compression Load Behaviour of Aluminium Alloy Foam Under the Diverse Strain Rate, J. Alloys Compd., 2016, 656, p 218–225

D.K. Rajak, L.A. Kumaraswamidhas, and S. Das, Energy Absorption Capacity of Empty and Foam Filled Mild Steel Tube Under Low Strain Rate at Room Temperature, Adv. Mater. Lett., 2015, 6(6), p 548–553

Acknowledgments

One of the authors, Dipen Kumar Rajak, gratefully acknowledges the experimental support of LWMM group CSIR-AMPRI, Bhopal. The authors thank Director, CSIR-AMPRI Bhopal and Indian Institute of Technology (Indian School of Mines) Dhanbad for giving permission to publish this research work. The technical support of the CSIR-AMPRI Bhopal during the Ph.D. research program of Dipen Kumar Rajak is highly appreciated.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Rajak, D.K., Kumaraswamidhas, L.A. & Das, S. Investigation of Mild Steel Thin-Wall Tubes in Unfilled and Foam-Filled Triangle, Square, and Hexagonal Cross Sections Under Compression Load. J. of Materi Eng and Perform 27, 1936–1944 (2018). https://doi.org/10.1007/s11665-018-3241-x

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-018-3241-x