Abstract

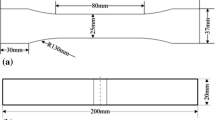

High-rotation-speed friction stir welding (HRS-FSW) is a promising technique to reduce the welding loads during FSW and thus facilitates the application of FSW for in situ fabrication and repair. In this study, 6061 aluminum alloy was friction stir welded at high-rotation speeds ranging from 3000 to 7000 rpm at a fixed welding speed of 50 mm/min, and the effects of rotation speed on the nugget zone macro- and microstructures were investigated in detail in order to illuminate the process features. Temperature measurements during HRS-FSW indicated that the peak temperature did not increase consistently with rotation speed; instead, it dropped remarkably at 5000 rpm because of the lowering of material shear stress. The nugget size first increased with rotation speed until 5000 rpm and then decreased due to the change of the dominant tool/workpiece contact condition from sticking to sliding. At the rotation speed of 5000 rpm, where the weld material experienced weaker thermal effect and higher-strain-rate plastic deformation, the nugget exhibited relatively small grain size, large textural intensity, and high dislocation density. Consequently, the joint showed superior nugget hardness and simultaneously a slightly low tensile ductility.

Similar content being viewed by others

References

R. Nandan, T. DebRoy, and H. Bhadeshia, Recent Advances in Friction-Stir Welding-Process, Weldment Structure and Properties, Prog. Mater Sci., 2008, 53, p 980–1023

G.E. Cook, R. Crawford, D.E. Clark, and A.M. Strauss, Robotic Friction Stir Welding, Ind. Robot: Int. J., 2004, 31, p 55–63

H. Atharifar, D.C. Lin, and R. Kovacevic, Numerical and Experimental Investigations on the Loads Carried by the Tool during Friction Stir Welding, J. Mater. Eng. Perform., 2009, 18, p 339–350

S. Zimmer, L. Langlois, J. Laye, J.C. Goussain, P. Martin, and R. Bigot, Determining the Ability of a High Payload Robot to Perform FSW Applications, in Proceedings of the 8th International Symposium on Friction Stir Welding, Timmendorfer Strand, Germany, 2010

J. Ding, R. Carter, K. Lawless, A. Nunes, C. Russell, M. Suits, and J. Schneider, Friction Stir Welding Flies High at NASA, Weld. J., 2006, 85, p 54–59

C. Smith, F. Pfefferkorn, L. Cerveny, E. Cole, A. Fehrenbacher, N. Ferrier, J. Hinrichs, E. Schultz, D. Wolf, and M. Zinn, Qualification of a Low Force FSW Process for Portable FSW to be Applied to Assembly of Large Structures, in Proceedings of the 8th International Symposium on Friction Stir Welding, Timmendorfer Strand, Germany, 2010

R. Kingston, J. Babb, S. Rose, J. Walser, C. Sorensen, T. Nelson, R. Steel, and M. Mahoney, Portable Friction Stir Welding Technology for Aluminium Fabrication, in Proceedings of the 8th International Symposium on Friction Stir Welding, Timmendorfer Strand, Germany, 2010

S. Rose, M. Mahoney, T. Nelson, and C. Sorensen, Tool Load and Torque Study for Portable Friction Stir Welding in Aluminum, in Proceedings of the Symposium on Friction Stir Welding and Processing VI held during 140th TMS Annual Meeting and Exhibition, San Diego, USA, 2011

H. Schmidt, J. Hattel, and J. Wert, An Analytical Model for the Heat Generation in Friction Stir Welding, Model. Simul. Mater. Sci. Eng., 2004, 12, p 143–157

A. Astarita, A. Squillace, and L. Carrino, Experimental Study of the Forces Acting on the Tool in the Friction-Stir Welding of AA 2024 T3 Sheets, J. Mater. Eng. Perform., 2014, 23, p 3754–3761

H.J. Aval, S. Serajzadeh, and A.H. Kokabi, Experimental and Theoretical Evaluations of Thermal Histories and Residual Stresses in Dissimilar Friction Stir Welding of AA5086-AA6061, Int. J. Adv. Manuf. Technol., 2012, 61, p 149–160

P. Ulysse, Three-Dimensional Modeling of the Friction Stir-Welding Process, Inter. J. Mach. Tool. Manuf., 2002, 42, p 1549–1557

R. Moshwan, F. Yusof, M.A. Hassan, and S.M. Rahmat, Effect of Tool Rotational Speed on Force Generation, Microstructure and Mechanical Properties of Friction Stir Welded Al-Mg-Cr-Mn (AA 5052-O) Alloy, Mater. Des., 2015, 66, p 118–128

J.K. Raghulapadu, J. Peddieson, G.R. Buchanan, and A.C. Nunes, A Rotating Plug Model of Friction Stir Welding Heat Transfer, Heat Transfer Eng., 2008, 29, p 321–327

M. Ahmad, Comprehensive Study of High Speed Friction Stir Welding, M.S. Thesis, Wichita State University, 2003

N. Banwasi, Mechanical Testing and Evaluation of High-Speed and Low-Speed Friction Stir Welds, M.S. Thesis, Wichita State University, 2005

C.A. Widener, J.E. Talia, B.M. Tweedy, and D.A. Burford, High-Rotational Speed Friction Stir Welding with a Fixed Shoulder, in Proceedings of the 6th International Symposium on Friction Stir Welding, Nr Montréal, Canada, 2006

R. Crawford, T. Bloodworth, G.E. Cook, and A.M. Strauss, High Speed Friction Stir Welding Process Modeling, in Proceedings of the 6th International Symposium on Friction Stir Welding, Nr Montréal, Canada, 2006

T. Nicholas, Advances in High Rotational Speed-Friction Stir Welding for NAVAL Applications, M.S. Thesis, Wichita State University, 2009

M. Wade and A.P. Reynolds, Friction Stir Weld Nugget Temperature Asymmetry, Sci. Technol. Weld. Join., 2010, 15, p 64–69

P.A. Colegrove and H.R. Shercliff, Experimental and Numerical Analysis of Aluminium Alloy 7075-T7351 Friction Stir Welds, Sci. Technol. Weld. Join., 2003, 8, p 360–368

Y.S. Sato, M. Urata, and H. Kokawa, Parameters Controlling Microstructure and Hardness During Friction-Stir Welding of Precipitation-Hardenable Aluminum Alloy 6063, Metall. Mater. Trans. A, 2002, 33, p 625–635

T. Wang, Y. Zou, and K. Matsuda, Micro-Structure and Micro-Textural Studies of Friction Stir Welded AA6061-T6 Subjected to Different Rotation Speeds, Mater. Des., 2016, 90, p 13–21

H.B. Schmidt and J.H. Hattel, A Thermal-Pseudo-Mechanical Model for the Heat Generation in Friction Stir Welding, in Proceedings of 7th International Symposium on Friction Stir Welding, Awaji Island, Japan, 2008

V. Dixit, R.S. Mishra, R.J. Lederich, and R. Talwar, Influence of Process Parameters on Microstructural Evolution and Mechanical Properties in Friction Stirred Al-2024 (T3) Alloy, Sci. Technol. Weld. Join., 2009, 14, p 346–355

D.X. Li, X.Q. Yang, L. Cui, F.Z. He, and H. Shen, Effect of Welding Parameters on Microstructure and Mechanical Properties of AA6061-T6 Butt Welded Joints by Stationary Shoulder Friction Stir Welding, Mater. Des., 2014, 64, p 251–260

M. Shiraly, M. Shamanian, M.R. Toroghinejad, and M. Ahmadi Jazani, Effect of Tool Rotation Rate on Microstructure and Mechanical Behavior of Friction Stir Spot-Welded Al/Cu Composite, J. Mater. Eng. Perform., 2014, 23, p 413–420

C.I. Chang, C.J. Lee, and J.C. Huang, Relationship between Grain Size and Zener-Holloman Parameter During Friction Stir Processing in AZ31 Mg Alloys, Scr. Mater., 2004, 51, p 509–514

Kh A.A. Hassan, A.F. Norman, and P.B. Prangnell, The Effect of Welding Conditions on the Microstructure and Mechanical Properties of the Nugget Zone in AA7010 Alloy Friction Stir Welds, in Proceedings of the 3rd International Symposium on Friction Stir Welding, Kobe, Japan, 2001

Y.S. Sato, Y. Kurihara, S.H.C. Park, H. Kokawa, and N. Tsuji, Friction Stir Welding of Ultrafine Grained Al Alloy 1100 Produced by Accumulative Roll-Bonding, Scr. Mater., 2004, 50, p 57–60

H.J. Aval, S. Serajzadeh, and A.H. Kokabi, Theoretical and Experimental Investigation into Friction Stir Welding of AA 5086, Int. J. Adv. Manuf. Technol., 2011, 52, p 531–544

Y.S. Sato, H. Kokawa, K. Ikeda, M. Enomoto, S. Jogan, and T. Hashimoto, Microtexture in the Friction-Stir Weld of an Aluminum Alloy, Metal. Mater. Trans. A, 2001, 32, p 941–948

R.W. Fonda, J.F. Bingert, and K.J. Colligan, Development of Grain Structure During Friction Stir Welding, Scr. Mater., 2004, 51, p 243–248

R.W. Fonda and J.F. Bingert, Texture Variations in an Aluminum Friction Stir Weld, Scr. Mater., 2007, 57, p 1052–1055

M.M.Z. Ahmed, B.P. Wynne, W.M. Rainforth, and P.L. Threadgill, Through-Thickness Crystallographic Texture of Stationary Shoulder Friction Stir Welded Aluminium, Scr. Mater., 2011, 64, p 45–48

F. Montheillet, P. Gilormini, and J.J. Jonas, Relation between Axial Stress and Texture Development During Torsion Testing, Acta Metall., 1985, 33, p 705–717

J.Q. Su, T.W. Nelson, R. Mishra, and M. Mahoney, Microstructural Investigation of Friction Stir Welded 7050-T651 Aluminium, Acta Mater., 2003, 51, p 713–729

G. İpekoğlu, S. Erim, and B. Gören, Kiral, and G. Çam, Investigation into the Effect of Temper Condition on Friction Stir Weldability of AA6061 Al-Alloy Plates, Kovove Mater., 2013, 51, p 155–163

G. İpekoğlu and G. Çam, Effects of Initial Temper Condition and Postweld Heat Treatment on the Properties of Dissimilar Friction-Stir-Welded Joints between AA7075 and AA6061 Aluminum Alloys, Metall. Mater. Trans. A, 2014, 45, p 3074–3087

S.D. Ji, X.C. Meng, L. Ma, and S.S. Gao, Effect of Groove Distribution in Shoulder on Formation, Macrostructures, and Mechanical Properties of Pinless Friction Stir Welding of 6061-O Aluminum Alloy, Inter. J. Adv. Manuf. Technol., 2016, 87, p 3051–3058

L.E. Svensson, L. Karlsson, H. Larsson, B. Karlsson, M. Fazzini, and J. Karlsson, Microstructure and Mechanical Properties of Friction Stir Welded Aluminium Alloys with Special Reference to AA 5083 and AA 6082, Sci. Technol. Weld. Join., 2000, 5, p 285–296

Y.S. Sato, S.H.C. Park, and H. Kokowa, Microstructural Factors Governing Hardness in Friction-Stir Welds of Solid-Solution-Hardened Al Alloy, Metall. Mater. Trans. A, 2001, 32, p 3033–3042

H. Aydın, A. Bayram, A. Uğuz, and K.S. Akay, Tensile Properties of Friction Stir Welded Joints of 2024 Aluminum Alloys in Different Heat-Treated-State, Mater. Des., 2009, 30, p 2211–2221

Acknowledgments

The authors are grateful to be supported by National Natural Science Foundation of China (Grant No. 51505471) and Innovation Fund from Youth Innovation Promotion Association Chinese Academy of Sciences (Grant No. 2015162).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhang, H.J., Wang, M., Zhu, Z. et al. Nugget Structure Evolution with Rotation Speed for High-Rotation-Speed Friction-Stir-Welded 6061 Aluminum Alloy. J. of Materi Eng and Perform 27, 1378–1386 (2018). https://doi.org/10.1007/s11665-018-3228-7

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-018-3228-7