Abstract

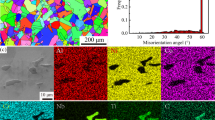

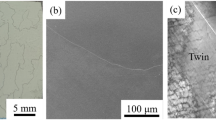

The Inconel 740 superalloy was prepared by the electron beam smelting (EBS) technology, the precipitation behavior and strengthening mechanism were studied, and the hot deformation characteristics of EBS 740 superalloy were investigated. The results indicate that the EBS 740 superalloy is mainly strengthened by the mechanism of weakly coupled dislocation shearing, and the resulting critical shear stress is calculated to be 234.6 MPa. The deformation parameters show a great influence on the flow behavior of EBS 740 superalloy. The strain rate sensitivity exponent increases with the increasing of deformation temperature, and the strain hardening exponent shows a decreasing trend with the increasing of strain. The activation energy of EBS 740 above 800 °C is measured to be 408.43 kJ/mol, which is higher than the 740H superalloy. A hyperbolic-sine-type relationship can be observed between the peak stress and Zener–Hollomon parameter. Nevertheless, the influence of deformation parameters is found to be considerably different at temperatures below and above 800 °C. The size of dynamic recrystallization (DRX) grains decreases with the increasing of strain rate when the strain rate is lower than 1/s, and reverse law can be found at higher strain rate. As a result, a piecewise function is established between the DRX grain size and hot working parameters.

Similar content being viewed by others

References

R. Viswanathan, K. Coleman, and U. Rao, Materials for Ultra-Supercritical Coal-Fired Power Plant Boilers, Int. J. Pres. Ves. Pip., 2006, 83, p 778–783

X. You, Y. Tan, J. Li, P. Li, C. Dong, S. Shi, J. Liao, and S. Qin, Effects of Solution Heat Treatment on the Microstructure and Hardness of Inconel 740 Superalloy Prepared by Electron Beam Smelting, J. Alloys Compd., 2015, 638, p 239–248

Y. Tan, X. You, Q. You, J. Li, S. Shi, and P. Li, Microstructure and Deformation Behavior of Nickel Based Superalloy Inconel 740 Prepared by Electron Beam Smelting, Mater. Charact., 2016, 114, p 267–276

X. You, Y. Tan, Q. You, S. Shi, J. Li, F. Ye, and X. Wei, Preparation of Inconel 740 Superalloy by Electron Beam Smelting, J. Alloys Compd., 2016, 676, p 202–208

A. Choudhury and E. Hengsberger, Elerctron Beam Melting and Refinining of Metals and Alloys, ISIJ Int., 1992, 32, p 673–681

H. Yuan and W.C. Liu, Effect of the δ Phase on the Hot Deformation Behavior of Inconel 718, Mater. Sci. Eng. A, 2005, 408, p 281–289

A. Thomas, M. El-Wahabi, J.M. Cabrera, and J.M. Prado, High Temperature Deformation of Inconel 718, J. Mater. Process. Technol., 2006, 177, p 469–472

L.M. Brown, R.K. Ham, Strengthening Methods in Crystals, A. Kelly, R.B. Nicholson, Eds., Halsted Press Division, Wiley, New York, NY, 1971, p 9

W. Huther and B. Reppich, Interaction of Dislocations with Coherent, Stree-Free Ordered Particles, Z. Fur Metallkunde, 1978, 69, p 628–634

M.P. Jackson and R.C. Reed, Heat Treatment of UDIMET 720Li: The Effect of Microstructure on Properties, Mater. Sci. Eng. A, 1999, 259, p 85–97

B. Reppich, Some New Aspects Concerning Particle Hardening Mechanisms in γ’ Precipitating Ni-base Alloys-I. Theoretical Concept, Acta Metall., 1982, 30, p 87–94

A.J. Ardell, Precipitation Hardening, Metall. Trans. A, 1985, 16, p 2131–2165

J.H. Oh, B.G. Yoo, I.C. Choi, M.L. Santella, and J.I. Jang, Influence of Thermo-Mechanical Treatment on the Precipitation Strengthening Behavior of Inconel 740, a Ni-Based Superalloy, J. Mater. Res., 2011, 26, p 1253–1259

H. Zhang, K. Zhang, Z. Lu, C. Zhao, and X. Yang, Hot Deformation Behavior and Processing Map of a γ′-Hardened Nickel-Based Superalloy, Mater. Sci. Eng. A, 2014, 604, p 1–8

W.A. Backofen, I.R. Turner, and D.H. Avery, Superplasticity in an Al–Zn Alloy, Trans. ASM, 1964, 57, p 980–990

A. Van den Beukel, Theory of the Effect of Dynamic Strain Aging on Mechanical Properties, Phys. Status Solidi (a), 1975, 30, p 197–206

K. Wang, M.Q. Li, J. Luo, and C. Li, Effect of the δ Phase on the Deformation Behavior in Isothermal Compression of Superalloy GH4169, Mater. Sci. Eng. A, 2011, 528, p 4723–4731

J. Luo and M.Q. Li, Strain Rate Sensitivity and Strain Hardening Exponent During the Isothermal Compression of Ti60 Alloy, Mater. Sci. Eng. A, 2012, 538, p 156–163

Y.M. Wang, A.M. Hodge, P.M. Bythrow, T.W. Barbee, Jr., and A.V. Hamza, Negative Strain Rate Sensitivity in Ultrahigh-Strength Nanocrystalline Tantalum, Appl. Phys. Lett., 2006, 89, p 081903

B.Q. Han, J. Huang, Y.T. Zhu, and E.J. Lavernia, Negative strain-Rate Sensitivity in a Nanostructured Aluminum Alloy, Adv. Eng. Mater., 2006, 8, p 945–947

J.H. Holloman, Tensile Deformations, Trans. Met. Soc. AIME, 1945, 162, p 268–290

C.M. Sellars and W.J.M.G. Tegart, Relationship Between Strength and Structure in Deformation at Elevated Temperatures, Mem. Sci. Rev. Met., 1966, 63, p 731

T. Sakai, Dynamic Recrystallization Microstructures Under Hot Working Conditions, J. Mater. Process. Tech., 1995, 53, p 349–361

A. Chamanfar, M. Jahazi, J. Gholipour, P. Wanjara, and S. Yue, Evolution of Flow Stress and Microstructure During Isothermal Compression of Waspaloy, Mater. Sci. Eng. A, 2014, 615, p 497–510

Y. Liu, R. Hu, J.S. Li, H.C. Kou, H.W. Li, H. Chang, and H.Z. Fu, Deformation Characteristics of As-Received Haynes 230 Nickel Base Superalloy, Mater. Sci. Eng. A, 2008, 497, p 283–289

Z.N. Bi, M.C. Zhang, J.X. Dong, K.J. Luo, and J. Wang, A New Prediction Model of Steady State Stress Based on the Influence of the Chemical Composition for Nickel-Base Superalloys, Mater. Sci. Eng. A, 2010, 527, p 4373–4382

V.V. Balasubrahmanyam and Y. Prasad, Deformation Behaviour of Beta Titanium Alloy Ti-10 V-4.5Fe-1.5 Al in Hot Upset Forging, Mater. Sci. Eng. A, 2002, 336, p 150–158

Y. Wang, W.Z. Shao, L. Zhen, L. Yang, and X.M. Zhang, Flow Behavior and Microstructures of Superalloy 718 During High Temperature Deformation, Mater. Sci. Eng. A, 2008, 497, p 479–486

J. Wang, J. Dong, M. Zhang, and X. Xie, Hot Working Characteristics of Nickel-Base Superalloy 740H During Compression, Mater. Sci. Eng. A, 2013, 566, p 61–70

R.L. Goetz and S.L. Semiatin, The Adiabatic Correction Factor for Deformation Heating During the Uniaxial Compression Test, J. Mater. Eng. Perform., 2001, 10, p 710–717

K. Song and M. Aindow, Grain Growth and Particle Pinning in a Model Ni-Based Superalloy, Mater. Sci. Eng. A, 2008, 479, p 365–372

Acknowledgments

The authors gratefully acknowledge financial support from the Specialized Research Fund for the National Key Research and Development Plan (Grant No. 2017YFA0403804).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

You, X., Tan, Y., Wu, C. et al. The Precipitation Behavior and Hot Deformation Characteristics of Electron Beam Smelted Inconel 740 Superalloy. J. of Materi Eng and Perform 27, 1580–1591 (2018). https://doi.org/10.1007/s11665-018-3193-1

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-018-3193-1