Abstract

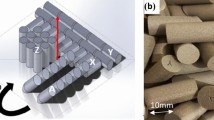

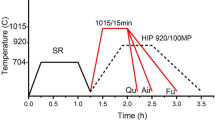

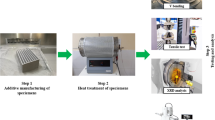

2219-Al parts were produced by gas tungsten arc-additive manufacturing and sequentially processed by an especial heat treatment. In order to investigate the effects of heat treatment on its mechanical properties, multiple tests were conducted. Hardness tests were carried out on part scale and layer scale along with tensile tests which were performed on welding and building directions. Results show that compared to conventional casting + T6 2219-Al, the current deposit + T6 2219-Al exhibits satisfying properties with regard to strength but unsatisfying results in plasticity. Additionally, anisotropy is significant. Fractures were observed and the cracks’ propagating paths in both directional specimens are described. The effects of heat treatment on the cracks’ initiation and propagation were also investigated. Ultimately, a revised formula was developed to calculate the strength of the deposit + T6 2219-Al. The aforementioned formula, which takes into consideration the belt-like porosities-distributing feature, can scientifically describe the anisotropic properties in the material.

Similar content being viewed by others

References

J.Y. Bai, J.H. Wang, S.B. Lin, C.L. Yang, and C.L. Fan, Width Prediction of Deposited Aluminium Alloy Manufactured by Shaped Metal Deposition with Tig, Trans. China Weld. Inst., 2015, 36, p 87–90 (in Chinese)

B. Baufeld, O.V. Biest, and R. Gault, Additive Manufacturing of Ti-6Al-4 V Components by Shaped Deposition: Microstructure and Mechanical Properties, Mater. Des., 2013, 31, p 106–111

S. Yang, M. Han, and Q. Wang, Development of a Welding System for 3D Steel Rapid Prototyping Process, China Weld., 2001, 1, p 50–56

J. Xiong and G.J. Zhang, Adaptive Control of Deposited Height in GMA-Based Layer Additive Manufacturing, J. Mater. Process Tech., 2014, 214, p 962–968

S.T. Skiba, B. Baufeld, and O.V. Biest, Shaped Metal Deposition of 300 M Steel, Proc. Inst. Mech. Eng. B J Eng., 2011, 225, p 831–839

H.J. Wang and R. Kovacevic, Rapid Prototyping of 4043 Al-Alloy Parts by VP-GTAW, J. Mater. Process Tech., 2004, 148, p 93–102

B. Baufeld, O.V. Biest, and R. Gault, Additive Manufacturing of Ti-6Al-4 V Components by Shaped Metal Deposition: Microstructure and Mechanical Properties, Mater. Des., 2010, 31, p 106–111

D. Clark, M.R. Bache, and M.T. Whittaker, Shaped Metal Deposition of a Nickel Alloy for Aero Engine Applications, J Mater Process Tech., 2008, 203, p 439–448

J.H. Wang, Research on Shaped Metal Deposition of 2219 Aluminum Alloy by AC-TIG Welding, Harbin Institute of Technology, Harbin, 2015 (in Chinese)

J.Y. Bai, C.L. Yang, S.B. Lin, B.L. Dong, and C.L. Fan, Mechanical Properties of 2219-Al Components Produced by Additive Manufacturing with TIG, Int. J. Adv. Manuf. Technol., 2016, 86, p 479–485

J.Y. Bai, C.L. Fan, S.B. Lin, C.L. Yang, and B.L. Dong, Effects of Thermal Cycles on Microstructure Evolution of 2219-Al During GTA-Additive Manufacturing, Int. J. Adv. Manuf. Technol., 2016, 87, p 2615–2623

B. Erhard and G. Daniel, Microstructure of Additive Layer Manufactured Ti–6Al–4 V After Exceptional Post Heat Treatments, Mater. Lett., 2015, 81, p 84–87

B. Erhard, S. Achim, and L. Christoph, Morphology, Microstructure, and Hardness of Titanium (Ti-6Al-4 V) Blocks Deposited by Wire-Feed Additive Layer Manufacturing (ALM), Mater. Sci. Eng., A, 2012, 532, p 295–307

Y. Aref, S. Nima, M.T. Scott, and W.S. Denver, Effects of Process Time Interval and Heat Treatment on the Mechanical and Microstructural Properties of Direct Laser Deposited 316L Stainless Steel, Mater. Sci. Eng., A, 2015, 644, p 171–183

F.J. Xu, Microstructure Control and Process Optimization of Inconel 625 Alloy Fabricated by Plasma Arc Rapid Prototyping, Harbin Institute of Technology, Harbin, 2013 (in Chinese)

Z.T. Wang, Heat Treatment of Wrought Aluminum Alloy, Central South University Press, Chang Sha, 2011 (in Chinese)

S. Malarvizhi and V. Balasubramanian, Effect of Welding Processes on AA2219 Aluminum Alloy Joint Properties, Trans. Nonferrous Met. Soc. China, 2011, 21, p 962–973

B. Cong, B.J. Qi, and X.G. Zhou, Influences of Ultrasonic Pulse Square-Wave Current Parameters on Microstructure and Mechanical Properties of 2219 Aluminum Alloy Weld Joints, Acta Metall. Sin., 2009, 45, p 1057–1062

J.W. Wyrzykowski and M.W. Grabski, The Hall-Petch Relation in Aluminum and its Dependence on the Grain Boundary Structure, Philos. Mag. A, 1986, 53, p 505–520

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Bai, J.Y., Fan, C.L., Lin, S.B. et al. Mechanical Properties and Fracture Behaviors of GTA-Additive Manufactured 2219-Al After an Especial Heat Treatment. J. of Materi Eng and Perform 26, 1808–1816 (2017). https://doi.org/10.1007/s11665-017-2627-5

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-017-2627-5