Abstract

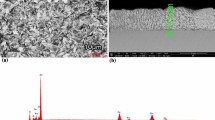

Brush plating provides an effective method for creating a coating on substrates of various shapes. A corroded zirconium-based conversion coating was removed from the surface of a magnesium alloy and then replaced with new coatings prepared via brush plating. The structure and composition of the remanufactured coating were determined via x-ray photoelectron spectroscopy, x-ray diffraction, and Fourier transform infrared spectroscopy. The results revealed that the coatings consist of oxide, fluoride, and tannin-related organics. The composition of the coatings varied with the voltage. Furthermore, as revealed via potentiodynamic polarization spectroscopy, these coatings yielded a significant increase in the corrosion resistance of the magnesium alloy. The friction coefficient remained constant for almost 300s during wear resistance measurements performed under a 1-N load and dry sliding conditions, indicating that the remanufactured coatings provide effective inhibition to corrosion.

Similar content being viewed by others

References

T. Ishizaki, Y. Masuda, and M. Sakamoto, Corrosion Resistance and Durability of Superhydrophobic Surface Formed on Magnesium Alloy Coated with Nanostructured Cerium Oxide Film and Fluoroalkylsilane Molecules in Corrosive NaCl Aqueous Solution, Langmuir, 2011, 27, p 4780–4788

W. Zhang, M. Li, Q. Chen, W. Hu, W. Zhang, and W. Xin, Effects of Sr and Sn on Microstructure and Corrosion Resistance of Mg-Zr-Ca Magnesium Alloy for Biomedical Applications, Mater. Des., 2012, 39, p 379–383

A. Zomorodian, F. Brusciotti, A. Fernandes, M. Carmezim, T.M. e Silva, J. Fernandes et al., Anti-Corrosion Performance of a New Silane Coating for Corrosion Protection of AZ31 Magnesium Alloy in Hank’s Solution, Surf. Coat. Technol., 2012, 206, p 4368–4375

G. Yoganandan, K.P. Premkumar, and J. Balaraju, Evaluation of Corrosion Resistance and Self-Healing Behavior of Zirconium-Cerium Conversion Coating Developed on AA2024 Alloy, Surf. Coat. Technol., 2015, 270, p 249–258

F. George, P. Skeldon, and G. Thompson, Formation of Zirconium-Based Conversion Coatings on Aluminium and Al-Cu Alloys, Corros. Sci., 2012, 65, p 231–237

A. Ghanbari and M. Attar, Surface Free Energy Characterization and Adhesion Performance of Mild Steel Treated Based on Zirconium Conversion Coating: A Comparative Study, Surf. Coat. Technol., 2014, 246, p 26–33

S.S. Golru, M. Attar, and B. Ramezanzadeh, Morphological Analysis and Corrosion Performance of Zirconium Based Conversion Coating on the Aluminum Alloy 1050, J. Ind. Eng. Chem., 2015, 24, p 233–244

J. Sun and G. Wang, Preparation and Corrosion Resistance of Cerium Conversion Coatings on AZ91D Magnesium Alloy by a Cathodic Electrochemical Treatment, Surf. Coat. Technol., 2014, 254, p 42–48

P.S. Correa, C.F. Malfatti, and D.S. Azambuja, Corrosion Behavior Study of AZ91 Magnesium Alloy Coated with Methyltriethoxysilane Doped with Cerium Ions, Prog. Org. Coat., 2011, 72, p 739–747

M. Zhao, J. Li, G. He, H. Xie, and Y. Fu, An Investigation of the Effect of a Magnetic Field on the Phosphate Conversion Coating Formed on Magnesium Alloy, Appl. Surf. Sci., 2013, 282, p 499–505

C. Wang, S. Zhu, F. Jiang, and F. Wang, Cerium Conversion Coatings for AZ91D Magnesium Alloy in Ethanol Solution and its Corrosion Resistance, Corros. Sci., 2009, 51, p 2916–2923

R. Zhang, S. Cai, G. Xu, H. Zhao, Y. Li, X. Wang et al., Crack Self-Healing of Phytic Acid Conversion Coating on AZ31 Magnesium Alloy by Heat Treatment and the Corrosion Resistance, Appl. Surf. Sci., 2014, 313, p 896–904

S. Pommiers-Belin, J. Frayret, A. Uhart, J.B. Ledeuil, J.C. Dupin, A. Castetbon et al., Determination of the Chemical Mechanism of Chromate Conversion Coating on Magnesium Alloys EV31A, Appl. Surf. Sci., 2014, 298, p 199–207

L. Niu, S.H. Chang, X. Tong, G. Li, and Z. Shi, Analysis of Characteristics of Vanadate Conversion Coating on the Surface of Magnesium Alloy, J. Alloys Compd., 2014, 617, p 214–218

A.S. Hamdy, I. Doench, and H. Möhwald, Intelligent Self-Healing Corrosion Resistant Vanadia Coating for AA2024, Thin Solid Films, 2011, 520, p 1668–1678

A. Rani, D. Somaiah, Megha, and M. Poddar, Scratch Cell Test: A Simple, Cost Effective Screening Tool to Evaluate Self-Healing in Anti-Corrosion Coatings, J. Mater. Eng. Perform., 2014, 23, p 3328–3335

A.S. Hamdy and M. Farahat, Chrome-Free Zirconia-Based Protective Coatings for Magnesium Alloys, Surf. Coat. Technol., 2010, 204, p 2834–2840

S.-X. Yu, R.-J. Zhang, Y.-F. Tang, Y.-L. Ma, and W.-C. Du, Composition and Performance of Nanostructured Zirconium Titanium Conversion Coating on Aluminum-Magnesium Alloys, J. Nanomater., 2013, 2013, p 1–8

H. Duan, K. Du, C. Yan, and F. Wang, Electrochemical Corrosion Behavior of Composite Coatings of Sealed MAO Film on Magnesium Alloy AZ91D, Electrochim. Acta, 2006, 51, p 2898–2908

M.A. Gonzalez-Nunez, C.A. Nunez-Lopez, P. Skeldon, G.E. Thompson, H. Karimzadeh, P. Lyon et al., A Non-Chromate Conversion Coating for Magnesium Alloys and Magnesium-Based Metal Matrix Composites, Corros. Sci., 1995, 37, p 1763–1772

X.H. Wang, J.H. Wang, X. Yue, and Y. Gao, Effect of Aging Treatment on the Exfoliation Corrosion and Stress Corrosion Cracking Behaviors of 2195 Al-Li Alloy, Mater. Des., 2015, 67, p 596–605

V. Nefedov, Y.V. Kokunov, Y.A. Buslaev, M.A. Poraikos, and A. Gustyako, Molecular Nitrogen as a Ligadn. A Study of Dinitrogen Complexes of Transition Metals, Diazocompounds, and Azides by X-ray Photoelectron Spectroscopy, Russ. J. Inorg. Chem., 1973, 18, p 931–934

C. Sleigh, A. Pijpers, A. Jaspers, B. Coussens, and R.J. Meier, On the Determination of Atomic Charge via ESCA Including Application to Organometallics, J. Electron. Spectrosc., 1996, 77, p 41–57

S. Roy, F. Juanita, and B. Jaime, Evidence of Chemical Reactions Between Di- and Poly-Glycidyl Ether Resins and Tannins Isolated from Pinus radiata D. Don bark, Bioresour Technol., 2005, 96, p 95–101

L. Chupin, C. Motillon, C.E. Bouhtoury, A. Pizzi, and B. Charrier, Characterisation of Maritime Pine (Pinus pinaster) Bark Tannins Extracted Under Different Conditions by Spectroscopic Methods, FTIR and HPLC, Ind. Crop. Prod., 2013, 49, p 897–903

G. Matamala, W. Smeltzer, and G. Droguett, Comparison of Steel Anticorrosive Protection Formulated with Natural Tannins Extracted from Acacia and from Pine Bark, Corros. Sci., 2000, 42, p 1351–1362

T. Hu, Y. Zhang, and L. Hu, Tribological Investigation of MoS2 Coatings Deposited on the Laser Textured Surface, Wear, 2012, 278–279, p 77–82

J. An, R.G. Li, Y. Lu, C.M. Chen, Y. Xu, X. Chen et al., Dry Sliding Wear Behavior of Magnesium Alloys, Wear, 2008, 265, p 97–104

A. Zafari, H.M. Ghasemi, and R. Mahmudi, Tribological Behavior of AZ91D Magnesium Alloy at Elevated Temperatures, Wear, 2012, 292–293, p 33–40

J.E. Gray and B. Luan, Protective Coatings on Magnesium and its Alloys—A Critical Review, J. Alloys Compd., 2002, 336, p 88–113

X. Chen, G. Li, J. Lian, and Q. Jiang, An Organic Chromium-Free Conversion Coating on AZ91D Magnesium Alloy, Appl. Surf. Sci., 2008, 255, p 2322–2328

Acknowledgments

This work was financially supported by the National Natural Science Foundation of China (Nos. 51575118, 51375106), National Basic Research Program of China (973 Program) (No. 61328303), China Postdoctoral Science Foundation (No. 2015M571390), Hei Long Jiang Postdoctoral Foundation (No. LBH-Z14050), Special Foundation for Harbin Science and Technology Innovation (No. 2015RAXXJ016) and Fundamental Research Funds for the Central Universities (No. HEUCFP2016154).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Liu, Z., Jin, G., Song, J. et al. Remanufacture of Zirconium-Based Conversion Coatings on the Surface of Magnesium Alloy. J. of Materi Eng and Perform 26, 1776–1783 (2017). https://doi.org/10.1007/s11665-017-2614-x

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-017-2614-x