Abstract

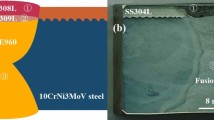

The explosively welded 2205 duplex stainless steel/X65 pipe steel bimetallic sheets were butt jointed by multilayer and multi-pass welding (gas tungsten arc welding for the flyer and gas metal arc welding for the transition and parent layers of the bimetallic sheets). The microstructure and mechanical properties of the welded joint were investigated. The results showed that in the thickness direction, microstructure and mechanical properties of the welded joint exhibited obvious inhomogeneity. The microstructures of parent filler layers consisted of acicular ferrite, widmanstatten ferrite, and a small amount of blocky ferrite. The microstructure of the transition layer and flyer layer consisted of both austenite and ferrite structures; however, the transition layer of weld had a higher volume fraction of austenite. The results of the microhardness test showed that in both weld metal (WM) and heat-affected zone (HAZ) of the parent filler layers, the average hardness decreased with the increasing (from parent filler layer 1 to parent filler layer 3) welding heat input. The results of hardness test also indicated that the hardness of the WM and the HAZ for the flyer and transition layers was equivalent. The tensile test combined with Digital Specklegram Processing Technology demonstrated that the fracturing of the welded joint started at the HAZ of the flyer, and then the fracture grew toward the base metal of the parent flyer near the parent HAZ. The stratified impact test at −5 °C showed that the WM and HAZ of the flyer exhibited lower impact toughness, and the fracture mode was ductile and brittle mixed fracture.

Similar content being viewed by others

References

M. Acarer, B. Gülenç, and F. Findik, Investigation of Explosive Welding Parameters and Their Effects on Microhardness and Shear Strength, Mater. Des., 2003, 24, p 659–664

S.A.A. Akbari-Mousavi, L.M. Barrett, and S.T.S. Al-Hassani, Explosive Welding of Metal Plates, J. Mater. Process. Technol., 2008, 202, p 224–239

S.A.A. Akbari Mousavi and P. Farhadi Sartangi, Experimental Investigation of Explosive Welding of CP-Titanium/AISI, 304 Stainless Steel, Mater. Des., 2009, 30, p 459–468

Q.L. Chu, M. Zhang, J.H. Li, Q.Y. Fan, W.W. Xie, and Z.Y. Bi, Joining of CP-Ti/Q345 Sheets by Cu-Based Filler Metal and Effect on Interface, J. Mater. Process. Technol., 2015, 225, p 67–76

K. Devendranath Ramkumar, G. Thiruvengatam, S.P. Sudharsan Debidutta Mishra, N. Debidutta Mishra, N. Arivazhagan, and R. Sridhar, Characterization of Weld Strength and Impact Toughness in the Multi-Pass Welding of Super-Duplex Stainless Steel UNS 32750, Mater. Des., 2014, 60, p 125–135

F. Grignon, D. Benson, K.S. Vecchio, and M.A. Meyers, Explosive Welding of Aluminum to Aluminum: Analysis, Computations and Experiments, Int. J. Impact Eng, 2004, 30, p 1333–1351

B. Gulenc, Investigation of Interface Properties and Weldability of Aluminum and Copper Plates by Explosive Welding Method, Mater. Des., 2008, 29, p 275–278

J.-B. Ju, W.S. Kim, and J. Jang, Variations in DBTT and CTOD Within Weld Heat-Affected Zone of API, X65 Pipeline Steel, Mater. Sci. Eng. A, 2012, 546, p 258–262

R. Kacar and M. Acarer, An Investigation on the Explosive Cladding of 316 l Stainless Steel-Din-P355GH Steel, J. Mater. Process. Technol., 2004, 152, p 91–96

N. Kahraman and B. Gülenç, Microstructural and Mechanical Properties of Cu-Ti Plates Bonded through Explosive Welding Process, J. Mater. Process. Technol., 2005, 169, p 67–71

Y.C. Chen, L.W. Tsay, and S.L.I. Chan, Sulfide Stress Corrosion Cracking and Fatigue Crack Growth of Welded TMCP API, 5 l X65 Pipe-Line Steel, Int. J. Fatigue, 2001, 23, p 103–113

M. Sadeghian, M. Shamanian, and A. Shafyei, Effect of Heat Input on Microstructure and Mechanical Properties of Dissimilar Joints between Super Duplex Stainless Steel and High Strength Low Alloy Steel, Mater. Des., 2014, 60, p 678–684

A.M. Torbati, R.M. Miranda, L. Quintino, and S. Williams, Welding Bimetal Pipes in Duplex Stainless Steel, Int. J. Adv. Manuf. Technol., 2010, 53, p 1039–1047

A.M. Torbati, R.M. Miranda, L. Quintino, S. Williams, and D. Yapp, Optimization Procedures for GMAW of Bimetal Pipes, J. Mater. Process. Technol., 2011, 211, p 1112–1116

Acknowledgments

The authors greatly acknowledge the support from the National High Technology Research and Development Program of China (Grant No. 2013AA031303HZ).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Gou, NN., Zhang, JX., Wang, JL. et al. Butt Welding of 2205/X65 Bimetallic Sheet and Study on the Inhomogeneity of the Properties of the Welded Joint. J. of Materi Eng and Perform 26, 1801–1807 (2017). https://doi.org/10.1007/s11665-017-2549-2

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-017-2549-2