Abstract

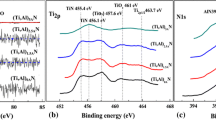

A gradient three-layer Al-Mo coating was deposited on steel using magnetron sputtering method. The corrosion and nano-mechanical properties of the coating were examined by electrochemical impedance spectroscopy and nano-indentation tests and compared with the conventional electroplated cadmium and IVD aluminum coatings. Electrochemical impedance spectroscopy was performed by immersing the coated specimens in 3.5% NaCl solution, and the impedance behavior was recorded as a function of immersion time. The mechanical properties (hardness and elastic modulus) were obtained from each indentation as a function of the penetration depth across the coating cross section. The adhesion resistance of the coatings was evaluated by scratch tests on the coated surface using nano-indentation method. The results show that the gradient Al-Mo coating exhibits better corrosion resistance than the other coatings in view of the better microstructure. The impedance results were modeled using appropriate electrical equivalent circuits for all the coated systems. The uniform, smooth and dense Al-Mo coating obtained by magnetron sputtering exhibits good adhesion with the steel substrate as per scratch test method. The poor corrosion resistance of the later coatings was shown to be due to the defects/cracks as well as the lesser adhesion of the coatings with steel. The hardness and elastic modulus of the Al-Mo coating are found to be high when compared to the other coatings.

Similar content being viewed by others

References

K.R. Baldwin and C.J.E. Smith, Advances in Replacements for Cadmium Plating in Aerospace Applications, Trans. Inst. Met. Finish., 1996, 74, p 202–209

E.M.K. Hillier and M.J. Robinson, Hydrogen Embrittlement of High Strength Steel Electroplated with Zinc-Cobalt Alloys, Corr. Sci., 2004, 46, p 715–727

M.J. Nelson and E.C. Groshart, Cadmium plating replacements, Aerospace environmental Technical Conference, Huntsville, Alabama, 10th-11th August 1994, p 277–284

P. Decker and K. Cramer, Development of alternate material selection system for cadmium replacement, Tri-service conference on corrosion, Wrightsville Beach, North Carolina, USA, Naval Surface Warfare Center, 17th-21st November, 1997, p 9.1–9.15

Prabhu Ganesan, Swaminatha P. Kumaraguru, and Branko N. Popov, Development of Compositionally Modulated Multilayer Zn-Ni Deposits as Replacement for Cadmium, Surf. Coat. Technol., 2007, 201, p 7896–7904

A. Conde, M.A. Avenas, and J.J. de Damborenea, Electrodeposition of Zn-Ni Coatings as Cd Replacement for Corrosion Protection of High Strength Steel, Corros. Sci., 2011, 53, p 1489–1492

C.J.E. Smith, Current requirements for the design and maintenance against corrosion of UK military aircraft, Advisory group for aerospace research and development (AGARD) Lecture Series No. 141 (1985) p. 6-1–6-13

C. Bowden and A. Matthews, A Study of the Corrosion Properties of PVD Zn-Ni Coatings, Surf. Coat. Technol., 1995, 76–77, p 508–515

E.V. Holmes, and J.J. Reilly, The substitution of IVD aluminum for cadmium, ESL-TR-90-28, Mcdonnel Aircraft company St. Louis MO, May 1990

B.R.W. Hinton, W.J. Pollock, P.N. Trathen, and A. Crosky, Ion Vapor Deposited Aluminum Coatings for the Corrosion Protection of Steel, Corros. Aust., 1987, 13, p 12–17

V.L. Holmes, M. Bridger, Aluminum coatings turn green: IVD process delivers environmentally friendly corrosion protection, Met. Finish., 2004, 102, p 6–10

C.E.F. Rob Mason, M. Neidbalson, M. Kungenberg, F.L.A. Largo, P. Khabra, and C. Handsy, Update on alternatives for cadmium coating on military electrical connectors, Met. Finish., 2010, 108, p 12–18

Q.S. Yu, J.E. Deffeyes, and H.K. Yasuda, Corrosion Protection of Ion Vapor Deposition (IVD) Al-Coated Al Alloys by Low Temperature Plasma Interface Engineering, Prog. Org. Coat., 2001, 42, p 100–109

A. Aguero, J.C. Del Hoyo, J. Garcia de Blas, M. Garcia, M. Gutierrez, L. Madueno, and S. Ulargui, Aluminum Slurry Coatings to Replace Cadmium for Aeronautic Applications, Surf. Coat. Technol., 2012, 213, p 229–238

N.M. Alanazi, A. Leyland, A.L. Yerokhin, and A. Matthews, Substitution of Hexavalent Chromate Conversion Treatment with a Plasma Electrolytic Oxidation Process to Improve the Corrosion Properties of Ion Vapour Deposited Al-Mg Coatings, Surf. Coat. Technol., 2010, 205, p 1750–1756

O.A. Fasuba, A. Yerokhin, A. Matthews, and A. Leyland, Corrosion Behavior and Galvanic Coupling with Steel of Al-Based Coating Alternatives to Electroplated Cadmium, Mater. Chem. Phys., 2013, 141, p 128–137

D.P. Monaghan, D.G. Teer, A. Logan, K.C. Laing, R.I. Bates, and R.D. Arness, An Improved Method for the Deposition of Corrosion-Resistant Aluminium Coatings for Aerospace Application, Surf. Coat. Technol., 1993, 60, p 592–596

K.R. Baldwin, R.I. Bates, R.D. Arnell, and C.J.E. Smith, Aluminium-Magnesium Alloys as Corrosion Resistant Coatings for Steel, Corros. Sci., 1996, 38, p 155–170

M. Bielawski, Development of Unbalanced Magnetron Sputtered Al-Mo Coatings for Cadmium Replacement, Surf. Coat. Technol., 2004, 179, p 10–17

A. Venugopal, P. Ramesh Narayanan, S.C. Sharma, and K.M. George, Electrochemical Corrosion Behavior of Magnetron-Sputtered Al-Mo Gradient Coated Steel in 3.5% NaCl Solution, J. Mater. Eng. Perform., 2016, 25, p 790–799

Aircraft steel specification H11 (equivalent to AMS 6485)

W.C. Oliver and G.M. Pharr, An Improved Technique for Determining Hardness and Sensing Indentation Experiments, J. Mater. Res., 1992, 24, p 1564–1583

Acknowledgments

The authors sincerely thank The Director, VSSC for his permission to publish the work.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Venugopal, A., Srinath, J., Ramesh Narayanan, P. et al. Corrosion and Nano-mechanical Behaviors of Magnetron Sputtered Al-Mo Gradient Coated Steel. J. of Materi Eng and Perform 26, 105–114 (2017). https://doi.org/10.1007/s11665-016-2413-9

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-016-2413-9