Abstract

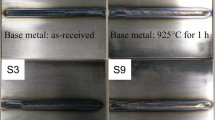

The effect of two preweld heat treatments on the final microstructure of a heat-affected zone (HAZ) and its effect on the weldability of the superalloy Inconel 939 have been analyzed. The HAZ cracking related to the mechanical driving force criteria during the cooling cycle was directly influenced by the strain state at this zone. Heat treatments result in the formation of (1) irregular γ′ precipitates (more negative misfits) which showed higher strain (high density of interfacial dislocations) and (2) spherical precipitates (near-zero misfits) which as a result of their structure improve weldability by reducing weld HAZ cracking considerably.

Similar content being viewed by others

References

M.A. González, D.I. Martínez, A. Pérez, H. Guajardo, and A. Garza, Microstructural Response to Heat Affected Zone Cracking of Prewelding Heat-Treated Inconel 939, Mater. Charact., 2011, 62, p 1116–1123

J. Tiley, G.B. Viswanathan, J.Y. Hwang, A. Shiveley, and R. Banerjee, Evalaution of Gamma Prime Volume Fractions and Lattice Misfits in a Nickel Base Superalloy Using Standard X-ray Diffraction Method, Mater. Sci. Eng. A, 2010, 528, p 32–36

S.A. David, S.S. Babu, and J.M. Vitek, Weldability and Microstructure Development in Nickel-Base Superalloys, Proc. Symp. Numer. Anal. Weld V, 1997, p 1-29.

O.M. Barabash, J.A. Horton, S.S. Babu, J.M. Vitek, S.A. David, J.W. Park, G.E. Ice, and R.I. Barabash, Evolution of Dislocation Structure in the Heat Affected Zone of a Nickel-Based Single Crystal, J. Appl. Phys., 2004, 96, p 3673–3679

S.S. Babu, M.K. Miller, J.M. Vitek, and S.A. David, Characterization of the Microstructure Evolution in a Nickel Base Superalloy During Continuos Cooling Conditions, Acta Mater., 2001, 49, p 14149–14160

A.K. Singh, N. Louat, and K. Sadananda, Dislocation Network Formation and Coherency Loos Around Gamma-Prime Precipitates in a Nickel-Base Superalloy, Metall. Trans. A, 1988, 19, p 2965–2973

M. Lachowicz, D. Wlodzimierz, and M. Podrez-Radziszewska, TEM Observation of the Heat-Affected Zone in Electron Beam Welded Superalloy Inconel 713C, Mater. Charact., 2008, 59, p 560–566

M.V. Nathal, R.A. Mackay, and R. Garlick, Temperature Dependance of γ-γ′ Lattice Mismatch in Nickel-Base Superalloys, Mater. Sci. Eng., 1985, 75, p 195–205

M.T. Rush, P.A. Colegrove, Z. Zhang, and B. Courtot, An Investigation into Cracking in Nickel-Base Superalloy Repair Welds, Adv. Mater. Res., 2010, 89-91, p 467–472

J.W. Park, J.W. Vitek, S.A. David and S.S. Babu, Thermo-Mechanical-Metallurgical Modelling of Cracking in Single Crystal Nickel-Base Superalloy Welds, US Department of Energy, 2005

M.A. González, D.I. Martínez, A. Pérez, and H. Guajardo, Microstructural Rejuvenation Trough Non-Conventional Heat Treatments of an Inconel 939 Superalloy, Proc. Symp. Mater. Res. Soc., 2011, 1372, p 1–8

W. Neumann, H. Kirmse, I. Hausler, A. Mogilatenko, C.H. Sheng, and W. Hetab, Advanced Microstructure Diagnostic and Interface Analysis of Modern Materials by High-Resolution Analytical Transmission Electron Microscopy, Bull. Polish Acad. Sci., 2010, 58, p 237–253

Y. Danis, C. Arvieu, E. Lacoste, T. Larrouy, and J.-M. Quenisset, An Investigation on Thermal, Metallurgical and Mechanical States in Weld Cracking of Inconel 738LC Superalloy, Mater. Des., 2010, 31, p 402–416

S. Kou, Precipitation-Hardening Materials II: Nickel-Base Alloys, Welding Metallurgy, 2nd ed., John Wiley & Sons, Inc., Hoboken, NJ, 2003, p 375–391

A. Somoza, G. Santos, A. Ges, R. Versaci, and F. Plazaola, Age-Hardening and Precipitation Phenomena in the Inconel-713C Superalloy Studied by Means of Positron Lifetime Spectroscopy, Phys. Stat. Solidi, 1999, 174, p 189–198

Y. Danis, E. Lacost, and C. Arvieu, Numerical Modeling of Inconel 738LC Deposition Welding: Prediction of Residual Stress Induced Cracking, Mater. Process. Technol, 2010, 210, p 2053–2061

D. Mukherji, R. Gilles, B. Barbier, DDel Genovese, B. Hasse, P. Struz, T. Wroblewski, H. Fuess, and J. Rosler, Lattice Misfit Measurement in Inconel 706 Containing Coherent γ′ and γ″ Precipitates, Scripta Mater., 2003, 48, p 333–339

J.H. Westbrook, Superalloys (Ni-Base) and Dislocations: An Introduction, Dislocations in Solids, 1996, p 1-26.

R.A. Ricks, A.J. Porter, and R.C. Ecob, The Growth of γ′ Precipitates in Nickel-Base Superalloys, Acta Metall., 1983, 31, p 43–53

J.X. Shang, J.C. Wang, H. Harada, and Y. Koizumi, The Effect of Lattice Misfit on the Dislocation Motion in Superalloys During High-Temperature Low-Stress Creep, Acta Mater., 2005, 53, p 4623–4633

T. Link, A. Ephishin, M. Klaus, U. Bruckner, and A. Reznicek, 〈100〉 Dislocation in Nickel-Base Superalloys: Formation and Role in Creep Deformation, Mater. Sci. Eng. A, 2005, 405, p 254–265

J. Li and R.P. Wahi, Investigation of γ/γ′ Lattice Mismatch in the Polycrystalline Nickel-Base Superalloy IN738: Influence of Heat Treatment and Creep Deformation, Acta Metall. Mater., 1995, 43, p 507–517

J.R.P. Djuansjah, K. Yashiro, and Y. Tomita, Computational Study on Misfit Dislocation in Ni-Based Superalloys by Quasicontinuum Method, Mater. Trans., 2008, 49, p 2507–2514

A. Thakur, Microstructural response of a nickel-base cast IN-738 superalloy to a variety of preweld heat-treatments, Metallurgical Science Laboratory, University of Manitoba, 1997, Thesis.

Acknowledgments

The authors would like to thank CONACyT Mexico and Paicyt for their financial support and also the Universidad Autonoma de Nuevo León and Corporación Mexican de Investigación en Materiales S.A. de C.V. for their technical support.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

González Albarrán, M.A., Martínez, D.I., Díaz, E. et al. Effect of Preweld Heat Treatment on the Microstructure of Heat-Affected Zone (HAZ) and Weldability of Inconel 939 Superalloy. J. of Materi Eng and Perform 23, 1125–1130 (2014). https://doi.org/10.1007/s11665-013-0704-y

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-013-0704-y