Abstract

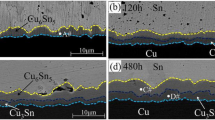

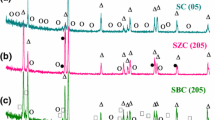

Recently In has been considered as an additional alloying element in Sn-rich solders primarily due to its abilities to decrease the solder melting temperature and to modify mechanical properties and microstructure. While In is an attractive candidate for addition to solder, its effect on solder microstructure is not well understood. In order to study the effect of minor In additions on Sn-rich solder alloys, solder joints were prepared using Sn-0.7 wt.% Cu and Sn-0.7 wt.% Cu- < 1 wt.% In alloys. Thermal aging and electromigration testing were done, followed by post-mortem microstructure characterization including composition, morphology, and grain structure. The addition of In did not appear to affect the microstructure under thermal aging conditions, but slowed interfacial intermetallic growth under electromigration, particularly of the compound Cu6Sn5. Transmission electron microscope analysis revealed the formation of Cu7In3 IMC nanoparticles, which were semicoherent with the surrounding Sn matrix.

Similar content being viewed by others

References

R.M. Shalaby, J. Mater. Sci. Mater. Electron. 26, 6625 (2015).

K. Kanlayasiri, M. Mongkolwongrojn, and T. Ariga, J. Alloys Compd. 485, 225 (2009).

S. Sommadossi and A.F. Guillermet, Intermetallics 15, 912 (2007).

S. Tian, S. Li, J. Zhou, and F. Xue, J. Alloys Compd. 742, 835 (2018).

L.F. Li, Y.K. Cheng, G.L. Xu, E.Z. Wang, Z.H. Zhang, and H. Wang, Mater. Des. 64, 15 (2014).

D.L. Wang, Y. Yuan, and L. Luo, IEEE Trans. Compon. Packag. Manuf. Technol. 2, 1275 (2012).

S. Tian, S. Li, J. Zhou, F. Xue, R. Cao, and F. Wang, J. Mater. Sci. Mater. Electron. 28, 16120 (2017).

P.T. Vianco, J.A. Rejent, A.F. Fossum, and M.K. Neilsen, J. Mater. Sci. Mater. Electron. 18, 93 (2007).

K. Kanlayasiri and K. Sukpimai, J. Alloys Compd. 668, 169 (2016).

J.P. Daghfal and J.K. Shang, J. Electron. Mater. 36, 1372 (2007).

Y. Li, A.B.Y. Lim, K. Luo, Z. Chen, F. Wu, and Y.C. Chan, J. Alloys Compd. 673, 372 (2016).

K. Lee, K.-S. Kim, and K. Suganuma, J. Mater. Res. 26, 467 (2011).

S.D. Mahapatra, B.S. Majumdar, I. Dutta, and S. Bhassyvasantha, J. Electron. Mater. 46, 4062 (2017).

C.R. Kao, Mater. Sci. Eng. A 238, 196 (1997).

X.J. Liu, H.S. Liu, I. Ohnuma, R. Kainuma, K. Ishida, S. Itabashi, K. Kameda, and K. Yamaguchi, J. Electron. Mater. 30, 1093 (2001).

Z. Bahari, E. Dichi, B. Legendre, and J. Dugue, Thermochim. Acta 401, 313 (2003).

S.-K. Lin, T.-Y. Chung, S.-W. Chen, and C.-H. Chang, J. Mater. Res. 24, 2628 (2009).

C. Schneider, W. Rasband, and K. Eliceiri, Nat. Methods 9, 671 (2012).

S.R. de Debiaggi, C.D. Toro, G.F. Cabeza, and A.F. Guillermet, J. Alloys Compd. 542, 280 (2012).

C.S. Schwandt, Microsc. Microanal. 20, 734 (2014).

C. Chen and S.W. Liang, J. Mater. Sci. Mater. Electron. 18, 259 (2007).

Acknowledgments

This work was funded by Intel Corporation. Experiments and characterization were completed at the Center for 4D Materials Science at Arizona State University.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Kelly, M.B., Antoniswamy, A., Mahajan, R. et al. Effect of Trace Addition of In on Sn-Cu Solder Joint Microstructure Under Electromigration. J. Electron. Mater. 50, 893–902 (2021). https://doi.org/10.1007/s11664-020-08602-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11664-020-08602-z