Abstract

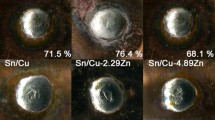

One of the suitable candidates to replace conventional high-temperature Pb-containing solders is Zn-xSn solder alloy. However, its high Zn content may cause poor wettability. Addition of Cu and Ti has been proposed to improve the wettability of Zn-25Sn solder alloy. This study investigated the wetting and intermetallic compound (IMC) formation behavior between Zn-25Sn-xCu-yTi solder alloys (x = 0.1 wt.% to 0.3 wt.%, y = 0.01 wt.% to 0.03 wt.%) and Cu substrate. The wetting behavior was investigated using a wetting balance with flux at a temperature ∼ 40°C above the liquidus temperature of Zn-25Sn solder. The results indicated that combined addition of 0.3 wt.% Cu and 0.03 wt.% Ti gave rise to the best performance in terms of wetting time and wetting force. CuZn5 and Cu5Zn8 IMCs formed at the solder–Cu interface, with Cu5Zn8 being the predominant layer. Cu5Zn8 also grew much faster than CuZn5 with respect to dipping time. Combined addition of Cu and Ti also decreased the activation energy for Cu5Zn8 IMC formation in the Zn-25Sn system.

Similar content being viewed by others

References

F.W. Gayle, G. Becka, J. Badgett, G. Whitten, T.Y. Pan, A. Grusd, B. Bauer, R. Lathrop, J. Slattery, I. Anderson, J. Foley, A. Gickler, D. Napp, J. Mather, and C. Olson, JOM 53, 17 (2001).

S. Menon, E. George, M. Osterman, and M. Pecht, J. Mater. Sci.: Mater. Electron. 26, 4021 (2015).

G. Zeng, S. McDonald, and K. Nogita, Microelectron. Reliab. 52, 1306 (2012).

V. Chidambaram, J. Hattel, and J. Hald, Microelectron. Eng. 88, 981 (2011).

S. Cheng, C.M. Huang, and M. Pecht, Microelectron. Reliab. 75, 77 (2017).

J.E. Lee, K.S. Kim, K. Suganuma, M. Inoue, and G. Izuta, Mater. Trans. 48, 584 (2007).

D.Q. Yu, H.P. Xie, and L. Wang, J. Alloys Compd. 385, 119 (2004).

W.C. Huang and K.L. Lin, J. Electron. Mater. 45, 6137 (2016).

L. Zou, D. Lea, and C. Hunt, Solderabilty Testing of Surface Mount Components and PCB Pads (Delhi: National Physical Laboratory, 2004).

Y.T. Wang, C.J. Ho, and H.L. Tsai, Mater. Trans. 51, 1735 (2010).

T.B. Massalski, H. Okamoto, P.R. Subramanian, and L. Kacprzak, Binary Alloy Phase Diagrams (Metals Park: ASM, 1986).

R. Mayappan and Z.A. Ahmad, Intermetallics 18, 730 (2010).

M.C. Wang, S.P. Yu, T.C. Chang, and M.H. Hon, J. Alloys Compd. 389, 133 (2005).

S.P. Yu, M.C. Wang, and M.H. Hon, J. Mater. Res. 16, 76 (2001).

L.J. Liu, P. Wu, and W. Zhou, Microelectron. Reliab. 54, 259 (2014).

R.R. Hultgren and A.S.F. Metals, Selected Values of Thermodynamic Properties of Binary Alloys. P.795-800 and P.810-822 (Metals Park: American Society for Metals, 1973).

S.W. Yoon, W.K. Choi, and H.M. Lee, Scripta Mater. 40, 327 (1999).

W. Fu, X.G. Song, Y.X. Zhao, J. Cao, J.C. Feng, C. Jin, and G.D. Wang, Mater. Des. 115, 1 (2017).

R. Sui, C. Ju, W. Zhong, and Q. Lin, J. Alloys Compd. 739, 616 (2018).

G. Zeng, S. Xue, L. Zhang, L. Gao, W. Dai, and J. Luo, J. Mater. Sci.: Mater. Electron. 21, 421 (2010).

Y. Yao, J. Zhou, F. Xue, and X. Chen, J. Alloys Compd. 682, 627 (2016).

M. Schaefer, R.A. Fournelle, and J. Liang, J. Electron. Mater. 27, 1167 (1998).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sarwono, D., Lin, KL. Wetting and IMC Growth Behavior Between Cu Substrate and Zn-25Sn-xCu-yTi High-Temperature Solder Alloys. J. Electron. Mater. 48, 99–106 (2019). https://doi.org/10.1007/s11664-018-6742-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11664-018-6742-3