Abstract

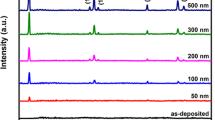

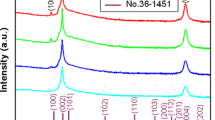

Nb and Ta co-doped anatase titanium dioxide (NTTO) nanocrystalline thin films were deposited on quartz and Si (100) substrates by RF magnetron sputtering. The influence of RF power on the growth, structure, morphology, and properties of the samples are discussed in detail. X-ray diffraction measurements show that the films are polycrystalline with anatase tetragonal structure, which is further confirmed by Raman spectroscopy analysis. Meanwhile, Raman spectroscopy results indicate that the peak width of Eg(1) mode, which is directly correlated to the carrier density, changes obviously with RF power. It is found that the substitution of Nb5+ and Ta5+ at Ti site is significantly improved with the increase of RF power from 150 W to 210 W. For the sample deposited at 210 W, the optical transmittance is above 82% in the visible range and the electrical resistivity is as low as 1.3 × 10−3 Ω cm with carrier density of 1.1 × 1021 cm−3 and Hall mobility of 4.5 cm2 V−1 s−1. The optical and electrical properties of NTTO thin films can be compared to those of Nb or Ta doped anatase TiO2. However, co-doping with Nb and Ta gives a possible platform to complement the limitations of each individual dopant.

Similar content being viewed by others

References

S. Seeger, K. Ellmer, M. Weise, D. Gogova, D. Abou-Ras, and R. Mientus, Thin Solid Films 605, 44 (2016).

E. Fortunato, P. Barquinha, A. Pimentel, A. Goncalves, A. Marques, L. Pereira, and R. Martins, Thin Solid Films 487, 205 (2005).

Y. Wang, M. Xu, J. Li, J. Ma, X. Wang, Z. Wei, X. Chu, X. Fang, and F. Jin, Surf. Coat. Technol. 330, 255 (2017).

Y. Wang, D.P. Wilkinson, V. Neburchilov, C. Song, A. Guest, and J. Zhang, J. Mater. Chem. A 2, 12681 (2014).

E.J.W. Crossland, N. Noel, V. Sivaram, T. Leijtens, J.A. Alexander-Webber, and H.J. Snaith, Nature 495, 215 (2013).

X. Lue, X. Mou, J. Wu, D. Zhang, L. Zhang, F. Huang, F. Xu, and S. Huang, Adv. Funct. Mater. 20, 509 (2010).

P.B. Nair, V.B. Justinvictor, G.P. Daniel, K. Joy, V. Ramakrishnan, and P.V. Thomas, Appl. Surf. Sci. 257, 10869 (2011).

M.A. Gillispie, M.F.A.M. van Hest, M.S. Dabney, J.D. Perkins, and D.S. Ginley, J. Mater. Res. 22, 2832 (2007).

K. Ok, Y. Park, K. Chung, and J. Park, Appl. Phys. Lett. 103, 213501 (2013).

Y. Furubayashi, T. Hitosugi, Y. Yamamoto, K. Inaba, G. Kinoda, Y. Hirose, T. Shimada, and T. Hasegawa, Appl. Phys. Lett. 86, 252101 (2005).

K. Safeen, V. Micheli, R. Bartali, G. Gottardi, A. Safeen, H. Ullah, and N. Laidani, Mater. Sci. Semicond. Process. 66, 74 (2017).

P. Mazzolini, P. Gondoni, V. Russo, D. Chrastina, C.S. Casari, and A.L. Bassi, J. Phys. Chem. C 119, 6988 (2015).

H. Anh Huy, B. Aradi, T. Frauenheim, and P. Deák, J. Appl. Phys. 112, 16103 (2012).

Y. Sato, H. Akizuki, T. Kamiyama, and Y. Shigesato, Thin Solid Films 516, 5758 (2008).

H. Lee and J. Robertson, J. Appl. Phys. 113, 213706 (2013).

D.H. Zhang, T.L. Yang, J. Ma, Q.P. Wang, R.W. Gao, and H.L. Ma, Appl. Surf. Sci. 158, 43 (2000).

S.S. Lin, J.L. Huang, and D.F. Lii, Surf. Coat. Technol. 176, 173 (2004).

V. Swamy, A. Kuznetsov, L.S. Dubrovinsky, R.A. Caruso, D.G. Shchukin, and B.C. Muddle, Phys. Rev. B 71, 184302 (2005).

M.V. Castro, L. Rebouta, P. Alpuim, M.F. Cerqueira, M. Benelmekki, C.B. Garcia, E. Alves, N.P. Barradas, E. Xuriguera, and C.J. Tavares, Thin Solid Films 550, 404 (2014).

C. Lejon and L. Osterlund, J. Raman Spectrosc. 42, 2026 (2011).

E. Uyanga, A. Gibaud, P. Daniel, D. Sangaa, G. Sevjidsuren, P. Altantsog, T. Beuvier, C.H. Lee, and A.M. Balagurov, Mater. Res. Bull. 60, 222 (2014).

S. Sahoo, A.K. Arora, and V. Sridharan, J. Phys. Chem. C 113, 16927 (2009).

P. Mazzolini, V. Russo, C.S. Casari, T. Hitosugi, S. Nakao, T. Hasegawa, and A.L. Bassi, J. Phys. Chem. C 120, 18878 (2016).

A.V. Manole, M. Dobromir, M. Girtan, R. Mallet, G. Rusu, and D. Luca, Ceram. Int. 39, 4771 (2013).

X.H. Xia, L. Lu, A.S. Walton, M. Ward, X.P. Han, R. Brydson, J.K. Luo, and G. Shao, Acta Mater. 60, 1974 (2012).

M.Z. Atashbar, H.T. Sun, B. Gong, W. Wlodarski, and R. Lamb, Thin Solid Films 326, 238 (1998).

M.V. Kuznetsov, A.S. Razinkin, and E.V. Shalaeva, J. Struct. Chem. 50, 514 (2009).

L. Lu, M. Guo, S. Thornley, X. Han, J. Hu, M.J. Thwaites, and G. Shao, Sol. Energy Mater. Sol. C 149, 310 (2016).

C. Huang, J. Bow, Y. Zheng, S. Chen, N.J. Ho, and P. Shen, Nanoscale Res. Lett. 5, 972 (2010).

H. Su, Y. Huang, Y. Chang, P. Zhai, N.Y. Hau, P.C.H. Cheung, W. Yeh, T. Wei, and S. Feng, Electrochim. Acta 182, 230 (2015).

H. Kim, M. Osofsky, S.M. Prokes, O.J. Glembocki, and A. Pique, Appl. Phys. Lett. 102, 171103 (2013).

K. Zhu, Y. Yang, and W. Song, Mater. Lett. 145, 279 (2015).

H. Tanaka, K. Ihara, T. Miyata, H. Sato, and T. Minami, J. Vac. Sci. Technol. A 22, 1757 (2004).

Y.M. Hu, J.Y. Li, N.Y. Chen, C.Y. Chen, T.C. Han, and C.C. Yu, J. Appl. Phys. 121, 85302 (2017).

G. Wan, S. Wang, X. Zhang, M. Huang, Y. Zhang, W. Duan, and L. Yi, Appl. Surf. Sci. 357, 622 (2015).

M. Neubert, S. Cornelius, J. Fiedler, T. Gebel, H. Liepack, A. Kolitsch, and M. Vinnichenko, J. Appl. Phys. 114, 083707 (2013).

Q. Ma, Z. Ye, H. He, J. Wang, L. Zhu, and B. Zhao, Vacuum 82, 9 (2007).

L. Nkhaili, A. El Kissani, M.A. Ali, Y. Ijdiyaou, A. Elmansouri, A. Elkhalfi, and A. Outzourhit, Eur. Phys. J. Appl. Phys. 66, 30302 (2014).

R.J. Hong, X. Jiang, B. Szyszka, V. Sittinger, and A. Pflug, Appl. Surf. Sci. 207, 341 (2003).

Z. Tseng, L. Chen, J. Tang, M. Shih, and S. Chu, J. Electron. Mater. 46, 1476 (2017).

H. Mahdhi, S. Alaya, J.L. Gauffier, K. Djessas, and Z. Ben, Ayadi. J. Alloys Compd. 695, 697 (2017).

R.G. Waykar, A.S. Pawbake, R.R. Kulkarni, A.A. Jadhavar, A.M. Funde, V.S. Waman, H.M. Pathan, and S.R. Jadkar, J. Mater. Sci. Mater. Electron. 27, 1134 (2016).

C.M. Maghanga, G.A. Niklasson, and C.G. Granqvist, Thin Solid Films 518, 1254 (2009).

P. Eiamchai, P. Chindaudom, A. Pokaipisit, and P. Limsuwan, Curr. Appl. Phys. 9, 707 (2009).

M. Rasheed and R. Barille, J. Non-cryst. Solids 476, 1 (2017).

Acknowledgements

The authors acknowledge the Analytical and Testing Center in Huazhong University of Science and Technology for XRD, SEM, XPS and Raman measurements. The finance support from the National Natural Science Foundation of China (11374114) is also acknowledged.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Liu, Y., Peng, Q., Qiao, Y. et al. Nb and Ta Co-Doped TiO2 Transparent Conductive Thin Films by Magnetron Sputtering: Fabrication, Structure, and Characteristics. J. Electron. Mater. 47, 5334–5343 (2018). https://doi.org/10.1007/s11664-018-6399-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11664-018-6399-y