Abstract

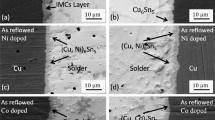

The growth behavior of intermetallic compound (IMC) in single crystal Sn3.0Ag0.5Cu (SAC305) and Sn3.0Ag3.0Bi3.0In (SABI333) ball grid array solder joints with Au/Ni/Cu pads under 104 A/cm2 current stressing was investigated. Characterization by scanning electron microscopy and electron backscattered diffraction mapping were utilized to identify the microstructure and crystal orientation of solder joints. The AuSn4 IMC particles in the SAC305 solder matrix were formed along the electron flow direction and c-axis direction of Sn. On the other hand, it was observed that the Au(Sn0.83, In0.17)4 IMC particles generated in SABI333 solder matrix decomposed from needle-like morphology into small pieces of Au(Sn0.23, In0.77)2 during current stressing. This phenomenon depends on the different diffusion rate and opposite migration direction of Sn and In atoms, which have different driving forces. Moreover, the results showed that the growth behavior of IMC particles in SAC305 solder joints was significantly dependent on the c-axis direction of Sn, while that of IMCs in SABI333 was almost maintained without polarization effect. This study indicated that SABI333 solder joints under EM service could exhibit a better performance than that of SAC305 solder joints.

Similar content being viewed by others

References

A.F. Abd El-Rehim, H.Y. Zahran, and S. AlFaify, J. Mater. Eng. Perform. 27, 344 (2018).

W.Q. Xing, X.Y. Yu, H. Li, L. Ma, W. Zuo, P. Dong, W.X. Wang, and M. Ding, J Alloys Compd. 695, 574 (2017).

H.-Y. Hsiao, Y.-S. Huang, and C. Chen, in 2011 IEEE 13th Electronics Packaging Technology Conference (2011), p. 474.

A.F. Abd El-Rehim and H.Y. Zahran, J. Alloys Compd. 695, 3666 (2017).

F. Guo, J. Mater. Sci.: Mater. Electron. 18, 129 (2007).

W.R. Osorio, D.R. Leiva, L.C. Peixoto, L.R. Garcia, and A. Garcia, J. Alloys Compd. 562, 194 (2013).

M. He, N. De Leon, and V.L. Acoff, Solder. Surf. Mt. Technol. 22, 4 (2010).

Y. Tian, J. Han, L.M. Ma, and F. Guo, Microelectron. Reliab. 80, 7 (2018).

S.K. Kang, M.G. Cho, P. Lauro, and D.Y. Shih, J. Mater. Res. 22, 557 (2007).

A.U. Telang, T.R. Bieler, J.P. Lucas, K.N. Subramanian, L.R. Lehman, Y. Xing, and E.J. Cotts, J. Electron. Mater. 33, 1412 (2004).

T.L. Yang, J.J. Yu, C.C. Li, Y.F. Lin, and C.R. Kao, J. Alloys Compd. 627, 281 (2015).

B.F. Dyson, J. Appl. Phys. 37, 2375 (1966).

B.F. Dyson, T.R. Anthony, and D. Turnbull, J. Appl. Phys. 38, 3408 (1967).

D.C. Yeh and H.B. Huntington, Phys. Rev. Lett. 53, 1469 (1984).

Y. Wang, J. Han, L.M. Ma, Y. Zuo, and F. Guo, J. Electron. Mater. 45, 6095 (2016).

M.L. Huang, J.F. Zhao, Z.J. Zhang, and N. Zhao, Acta Mater. 100, 98 (2015).

K.N. Tu, Microelectron. Reliab. 51, 517 (2011).

L. Ma, X. Guangchen, F. Jia Sun, F. Guo, and X. Wang, J. Mater. Sci. 46, 4896 (2011).

T.C. Huang, T.L. Yang, J.H. Ke, C.H. Hsueh, and C.R. Kao, Scr. Mater. 80, 37 (2014).

C.E. Ho, C.H. Yang, and L.H. Hsu, Surf. Coat. Technol. 259, 257 (2014).

Y. Tian, J. Han, and F. Guo, J. Mater. Sci.: Mater. Electron. 28, 10785 (2017).

Y. Kim, S. Nagao, T. Sugahara, K. Suganuma, M. Ueshima, H.J. Albrecht, K. Wilke, and J. Strogies, J. Electron. Mater. 43, 4428 (2014).

A. Yamaguchi, Y. Yamashita, A. Furusawa, K. Nishida, T. Hojo, Y. Sogo, A. Miwa, A. Hirose, and K.F. Kobayashi, Mater. Trans. 45, 1282 (2004).

K.-S. Kim, T. Imanishi, K. Suganuma, M. Ueshima, and R. Kato, Microelectron. Reliab. 47, 1113 (2007).

K. Suganuma, K. Niihara, T. Shoutoku, and Y. Nakamura, J. Mater. Res. 13, 2859 (1998).

M.S. Yeh, Metall. Mater. Trans. A 34, 361 (2003).

K. Yamanaka, Y. Tsukada, and K. Suganuma, J. Alloys Compd. 437, 186 (2007).

A.T. Wu, M.H. Chen, and C.H. Huang, J. Alloys Compd. 476, 436 (2009).

A.T. Wu and K.H. Sun, J. Electron. Mater. 38, 2780 (2009).

J. Chen, J. Shen, W.D. Xie, and H. Liu, J. Mater. Sci.: Mater. Electron. 22, 1703 (2011).

C.C. Jain, S.S. Wang, K.W. Huang, and T.H. Chuang, J. Mater. Eng. Perform. 18, 211 (2009).

H.M. Wu, F.C. Wu, and T.H. Chuang, J. Electron. Mater. 34, 1385 (2005).

Y. Li, F.S. Wu, and Y.C. Chan, J. Mater. Sci.: Mater. Electron. 26, 8522 (2015).

S.K. Seo, S.K. Kang, M.G. Cho, D.Y. Shih, and H.M. Lee, J. Electron. Mater. 38, 2461 (2009).

C.E. Ho, C.H. Yang, P.T. Lee, and C.T. Chen, Scr. Mater. 114, 79 (2016).

C.F. Lin, S.H. Lee, and C.M. Chen, Metall. Mater. Trans. A 43a, 2571 (2012).

P.S. Ho and T. Kwok, Rep. Prog. Phys. 52, 301 (1989).

H. Conrad, Mat Sci Eng a-Struct. 287, 227 (2000).

A. Sawatzky, J. Appl. Phys. 29, 1303 (1958).

K.G. Davis, Metall. Trans. 5, 303 (1974).

E.I. Kharkov, S.Y. Yakushevskiy, G.I. Onopriyenko, and R.F. Alimova, Izv. Akad. Nauk SSSR Met. 1, 56 (1974).

Acknowledgments

The authors acknowledge the support of this work from the National Natural Science Foundation of China (Grant Numbers 51425101 and 51621003), the Beijing Natural Science Foundation (Grant Numbers 2162005, 2172009, and 2172006), and the Science and Technology Nova Plan of Beijing (Grant Number Z161100004916155).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Tian, Y., Wang, Y., Guo, F. et al. The Evolution of IMCs in Single Crystal Sn3.0Ag0.5Cu and Sn3.0Ag3.0Bi3.0In BGA Solder Joints with Au/Ni/Cu Pads Under Current Stressing. J. Electron. Mater. 48, 2770–2779 (2019). https://doi.org/10.1007/s11664-018-06907-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11664-018-06907-8