Abstract

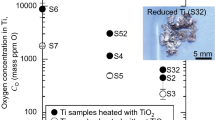

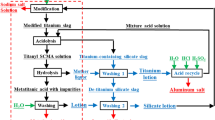

The development of a new titanium (Ti) smelting process is highly desired to decrease the cost of Ti metal. In this study, a new method to produce a low-oxygen-concentration Ti directly from TiO2 using La as the reductant was developed. First, deoxidation experiments of metallic Ti using La as the deoxidant were conducted, and the ability of La to deoxidize metallic Ti was demonstrated. The oxygen concentrations in Ti were approximately 3900 ± 400 mass ppm O and 120 ± 50 mass ppm O at La/La2O3 and La/LaOCl/LaCl3 equilibria, respectively, at 1200 K (927 °C). Then, TiO2 reduction experiments utilizing La as the reductant were conducted to produce low-oxygen-concentration Ti directly. TiO2 pellets and Ti pieces were held in LaCl3 molten salt with a sufficient amount of La at 1200 K (927 °C) for 86 ks. After the reaction, the TiO2 pellets were reduced to metallic Ti without reaction inhibition by the formation of intermediate products. The oxygen concentration of the Ti pieces, which were placed in the molten salt with the TiO2 pellets, was 100 ± 50 mass ppm O. These results indicate that low-oxygen-concentration Ti containing less than 200 mass ppm O could be produced directly from TiO2 by utilizing La as the reductant in LaCl3 molten salt at 1200 K (927 °C). This new method is expected to lead to the development of a new industrial process for the production of ultra-low-oxygen-content Ti from Ti ore without a chlorination process.

Similar content being viewed by others

References

W. Kroll: Trans. Electrochem. Soc., 1940, vol. 78, pp. 35-47.

T.H. Okabe: J. Jpn. Inst. Light Met., 2005, vol. 55, pp. 537-43.

O. Kubaschewski and W.A. Dench: J. Inst. Metals, 1953-54, vol. 82, pp. 87–91.

K.L. Komarek and M. Silver: Proc. IAEA Symp., Thermodynamics of Nuclear Materials, Wien, 1962, pp. 749–74.

T.H. Okabe, C. Zheng, and Y. Taninouchi: Metall. Mater. Trans. B, 2018, vol. 49B, pp. 1056-66.

F.M. Perkin and L. Pratt: Trans. Faraday Soc., 1907, Vol. 3, pp. 179-86.

M. Hasegawa: J. Jpn. Inst. Met. A, 1950, vol. 14, pp. 23-26.

M.E. Sibert and M.A. Steinberg: J. Met., 1956, vol. 8, pp. 1162-68.

T. A. Henrie: High Temp. Refrac Met., 1968, vol. 34, pp. 139-54.

T. Oki and H. Inoue: Mem. Fac. Eng., Nagoya Univ., 1967, vol. 19, pp. 164–66.

F. H. Hayes, H. B. Bomberger, F. H. Froes, L. Kaufman, and H. M. Burte: J. Met. (JOM), 1984, vol. 36, pp. 70–76.

K. Ono and S. Miyazaki: J. Jpn. Inst. Met., 1985, vol. 49, pp. 871–75.

K. Ono, M. Ogawa, T.H. Okabe, and R.O. Suzuki: Tetsu to Hagane (J. Iron and Steel Inst. Jpn.), 1990, vol. 76, pp. 568–75.

T.H. Okabe: Ph.D. Thesis, Kyoto University, (23-Mar-1993), https://doi.org/10.11501/3066235, URL: http://hdl.handle.net/2433/74621, 1993, pp. 1–209.

T. H. Okabe, T. Oda, and Y. Mitsuda: J. Alloys Compd., 2004, vol. 364, pp. 156-63.

I. Park, T. Abiko, and T.H. Okabe: J. Phys. Chem. Solids, 2005, vol. 66, pp. 410–13.

D.J. Fray, T.W. Farthing, and G.Z. Chen: International Patent, WO1999064638A1, 1999.

G. Z. Chen, D. J. Fray and T. W. Farthing: Nature, 2000, vol. 407, pp. 361-64.

D.J. Fray: J. Met. (JOM), 2001, vol. 53, pp. 26–31.

G.Z. Chen, D.J. Fray, and T.W. Farthing: Metall. Mater. Trans. B, 2001, vol. 32, pp. 1041-52.

K. Ono and R.O. Suzuki: Materia Japan (Nippon Kinzoku Gakkai Kaiho), 2002, vol. 41, pp. 28–31.

K. Ono and R.O. Suzuki: J. Met. (JOM), 2002, vol. 54, pp. 59–61.

R.O. Suzuki and K. Ono: Electrochem. Soc. Proc., 2002, vol. 19, pp. 810–21.

R. Suzuki and S. Inoue: Metall. Mater. Trans. B, 2003, vol. 34, pp. 277-85.

D.W. Rostron: US patent 2,834,667, May 13, 1958.

J.M.J. Paixao, F.T.D. Almeida, and M.J.D.F. Mourao: UK patent, GB2158102A, 1985.

M. Maeda, T. Yahata, K. Mitugi, and T. Ikeda: Mater. Trans. JIM, 1993, vol. 34, pp. 599–603.

H.H. Nersisyan, J.H. Lee, and C.W. Won: Mater. Res. Bull., 2003, vol. 38, pp. 1135-46.

Y. Zhang, Z. Z. Fang, Y. Xia, P. Sun, B. V. Devener, M. Free, H. Lefler and S. Zheng: Chem. Eng. J., 2017, vol. 308, pp. 299-310.

H. Lefler, Z. Z. Fang, Y. Zhang, P. Sun and Y. Xia: Metall. Mater. Trans. B, 2018, vol. 49, pp. 2998-3006.

T. H. Okabe, K. T. Jacob and Y. Waseda: Purification Process and Characterization of Ultra High Purity Metals, Springer, Berlin, Heidelberg, 2002, pp. 3-37.

W. Muthmann and L. Weiss: Justus Liebigs Ann. Chem., 1904, vol. 331, pp. 1-46.

W. Muthmann and L. Weiss: Justus Liebigs Ann. Chem., 1907, vol. 351, pp. 59-99.

R. Vogel: Ferrum, 1917, vol. 14, pp. 177-97.

J. Lucas, P. Lucas, T. L. Mercier, A. Rollat, and W. Davenport: Rare Earth Science, Technology, Production and Use, Elsevier B. V., 2015.

T.H. Okabe, Y. Taninouchi, and C. Zheng: Metall. Mater. Trans. B, 2018, vol. 49B, pp.3107-17.

C. Zheng, T. Ouchi, A. Iizuka, Y. Taninouchi and T. H. Okabe: Metall. Mater. Trans. B, 2019, vol. 50, pp. 622-31.

C. Zheng, T. Ouchi, L. Kong, Y. Taninouchi and T. H. Okabe: Metall. Mater. Trans. B, 2019, vol. 50, pp. 1652-61.

L. Kong, T. Ouchi, and T.H. Okabe: Mater. Trans., JIM, 2019, vol. 60, pp. 2059–68.

L. Kong, T. Ouchi, C. Zheng and T. H. Okabe: J. Electrochem. Soc., 2019, vol. 166, pp. E429-37.

The rare metal news, arum-shuppan, 2019, pp. 3–9.

The rare metal news, arum-shuppan, 2019, no. 2838, p. 5.

I. Barin: Thermochemical Data of Pure Substance, 3rd ed., Wiley-VCH, Weinheim, Germany, 1995.

O. Knacke, O. Kubaschewski and K. Hesselmann: Thermochemical Properties of Inorganic Substances, 2nd ed., Springer-Verlag, Berlin, Germany, 1991.

Y. B. Patrikeev, G. I. Novikov and V. V. Badovskii: Russ. J. Phys. Chem., 1973, vol. 47, p. 284.

T.H. Okabe, R.O. Suzuki, T. Oishi, and K. Ono: Mater. Trans. JIM, 1991, vol. 32, pp. 485–88.

C. K. Gupta and N. Krishnamurthy: Miner. Metall. Process., 2013, vol. 30, pp. 38-44.

A. H. Daane, D. H. Dennison and F. H. Spedding: J. Am. Chem. Soc., 1953, vol. 75, pp. 2272-73.

F. H. Spedding, J. J. Hanak and A. H. Daane: Trans. Metall. Soc. AIME, 1958, vol. 212, pp. 379-83.

J. L. Moriarty Jr.: J. Met., 1968, vol. 20, pp.41-45.

A. Iizuka, T. Ouchi, and T.H. Okabe: Metall. Mater. Trans. B, 2020, vol. 51, pp. 433-42.

A. K. Baev and G. I. Novikov: Russ. J. Inorg. Chem., 1965, vol. 10, pp. 1337-41.

J. P. Gaviría, L. G. Navarro, and A. E. Bohé: J. Phys. Chem. A, 2012, vol. 116, pp. 2062-70.

W. Gong and R. Zhang: Thermochimica Acta, 2012, vol. 534, pp. 28-32.

Acknowledgments

The authors are grateful to Mr. Akihiro Iizuka and Dr. Lingxin Kong at The University of Tokyo for their effective recommendations. This work was financially supported by the Japan Society for the Promotion of Science (JSPS) through a Grant-in-Aid for Scientific Research (S) (KAKENHI Grant Nos. 26220910 and 19H05623).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted November 20, 2019.

Rights and permissions

About this article

Cite this article

Tanaka, T., Ouchi, T. & Okabe, T.H. Lanthanothermic Reduction of TiO2. Metall Mater Trans B 51, 1485–1494 (2020). https://doi.org/10.1007/s11663-020-01860-6

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-020-01860-6