Abstract

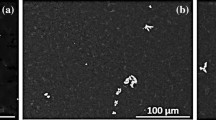

This work presents the agglomeration mechanism of complex Ti-Al oxides in the liquid ferrous alloy. Cluster characteristics were investigated using Al and Ti/Al-complex deoxidation method in lab scale. The time-dependent size distribution, total number per volume, average size, and circularity of the clusters were quantitatively analyzed. Furthermore, high-temperature confocal laser scanning microscopy was utilized to directly observe the cluster formation of Ti-Al oxides. A capillary force model including wettability parameters was applied to compare the agglomeration capabilities of different types of non-metallic inclusions. When a low Ti is added into melt, the agglomeration of TiOx·FeO liquid inclusions is one of the key factors to decrease the frequency of cluster formation. When the Al is added into melt, the heterogeneous precipitation on TiOx·FeO surfaces is the main reaction process. Ti-Al oxides have lower agglomeration ability than that of Al2O3, which in turn, contribute to a low agglomeration frequency as well.

Similar content being viewed by others

References

A. Rahmel and P. J. Spencer: Oxid. Metals, 1991, vol. 35, pp. 53-68.

K. L. Luthra: Oxid. Metals, 1991, vol. 36, pp. 475-490.

B. J. Lee and N. Saunders: Zeitschrift für Metallkunde, 1997, vol. 88, pp. 152-161.

S. Das: J. Ph. Eq., 2002, vol. 23, pp. 525-536.

H. J. Seifert, A. Kussmaul and F. Aldinger: J. Alloy Compounds, 2001, vol. 317, pp. 19-25.

M. J. Mas-Guindal, E. Benko and M. A. Rodriguez: J. Alloy Compounds, 2008, vol. 454, pp. 352-358.

I. Bellemans, E. D. Wilde, N Moelans and K. Verbeken: Ad. Colloid Interface Sci., 2018, vol. 255, pp. 47-63.

A. P. Weber and S. K. Friedlander: J. Aerosol Sc., 1997, vol. 28, pp. 179-192.

T. G. Anjali and M. G. Basavaraj: J. Colloid Interface Sci., 2016, vol. 478, pp. 63-71.

N. Sinn, M. Alishahi and S. Hardt: J. Colloid Interface Sci., 2015, vol. 458, pp. 62-68.

C. J. Xuan, A. V. Karasev, P. G. Jönsson and K. Nakajima: Steel Res. Int., 2017, vol. 88, 1600090.

W. Mu, N. Dogan and K. S. Coley: J. Mater Sci., 2018, vol. 53, pp. 13203-13215.

W. Mu, P. G. Jönsson, and K. Nakajima: High Temp. Mater. Processes, 2017, vol. 36, pp. 309-325.

W. Mu, P. G. Jönsson, and K. Nakajima: ISIJ Int., 2014, 54, pp. 2907-2916.

E. Dickinson and L. Eriksson: Adv. Coll. Interface Sci., 1991, vol. 34, pp. 1-29.

W. Mu, N. Dogan and K. S. Coley: Metall. Mater. Trans. B, 2017, vol. 48, pp. 2379-2388.

W. Mu, N. Dogan and K. S. Coley: Metall. Mater. Trans. B, 2017, vol. 48, pp. 2092-2103.

W. Mu, N. Dogan and K. S. Coley: JOM, 2018, vol. 70, pp. 1199-1209.

C. Xuan, A. V. Karasev and P. G. Jönsson: ISIJ Int., 2016, vol. 56, pp. 1204-1209.

G. Kaptay: Ad. Colloid Interface Sci., 2018, vol. 256, pp. 163-192.

G. Kaptay: J. Mater. Sci., 2005, vol. 40, pp. 2125-2131.

O. Wijk: Inclusion Engineering. Proc. 7th Int. Conf. Refining Process (SCANINJECT VII), Luleå, Sweden, 1995, pp. 35–67.

L. Holappa and O. Wijk: Inclusion Engineering. Treatise on Process Metallurgy: Industrial Processes, 2014, pp. 347-372.

W. Mu, P. G. Jönsson and K. Nakajima: J. Mater. Sci., 2016, vol. 51, pp. 2168-2180.

K. J. Malmberg, H. Shibata, S. Y. Kitamura, P. G. Jönsson, S. Nabeshima and Y. Kishimoto: J. Mater. Sci., 2010, vol. 45, pp. 2157-2164.

J. Janis, K. Nakajima, A. Karasev, H. Shibata and P. G. Jönsson: J. Mater. Sci., 2010, vol. 45, pp. 2233-2238.

D. Zhang, Y. Shintaku, S. Suzuki and Y. I. Komizo: J. Mater. Sci., 2012, vol. 47, pp. 5524-5528.

X. L. Wan, R. Wei, L. Cheng, M. Enomoto and Y. Adachi: J. Mater. Sci., 2013, vol. 48, pp. 4345-4355.

W. Mu, H. Shibata, P. Hedström, P. G. Jönsson and K. Nakajima: Metall. Mater. Trans. B, 2016, vol. 47, pp. 2133-2147.

C. Xuan, M. Mu, Z. I. Olano, P. G. Jönsson and K. Nakajima: Steel Res. Int., 2016, vol. 87, pp. 911-920.

W. Mu, H. Shibata, P. Hedström, P. G. Jönsson and K. Nakajima: Steel Res. Int., 2016, vol. 87, pp. 10-14.

H. Matsuura, C. Wang, G. Wen and S. Sridhar: ISIJ Int., 2007, vol. 47, pp. 1265-1274.

C. Wang, N. T. Nuhfer and S. Sridhar: Metall. Mater. Trans. B, 2009, vol. 40, pp. 1005-1021.

C. Wang, N. T. Nuhfer and S. Sridhar: Metall. Mater. Trans. B, 2009, vol. 40, pp. 1022-1034.

C. Wang, N. T. Nuhfer and S. Sridhar: Metall. Mater. Trans. B, 2010, vol. 41, pp. 1084-1094.

M. Li, H. Matsuura and F. Tsukihashi: Metall. Mater. Trans. B, 2017, vol. 48, pp. 1915-1923.

M. Li, H. Matsuura and F. Tsukihashi: Metall. Mater. Trans. A, 2018. https://doi.org/10.1007/s11661-018-5015-3.

M. Li, H. Matsuura and F. Tsukihashi: Mater. Characterization, 2018, vol. 136, pp. 358-366.

M. K. Sun, I. H. Jung and H. G. Lee: Met. Mater. Int., 2008, vol. 14, pp. 791-798.

I. H. Jung, S. A. Decterov and A. D. Pelton: ISIJ Int., 2004, vol. 44, pp. 527-536.

S. A. Decterov, I. -H. Jung, E. Jak. Y.-B. Kang, P. Hayes and A. D. Pelton: Proc. 7th Int. Conf. Molten Slags, Fluxes and Salts, Café Town, South Africa, 2004, pp. 839-850.

F. Ruby-Meyer, J. Lehmann and H. Gaye: Scand. J. Metall., 2000, vol. 29, pp. 206-212.

W. Choi, H. Matsuura and F. Tsukihashi: ISIJ Int., 2011, vol. 51, pp. 1951-1956.

T. Nakaoka, S. Taniguchi, K. Matsumoto and S. T. Johansen: ISIJ Int., 2001, vol. 41, pp. 1103-1111.

H. Lei, L. Wang, Z. Wu and J. Fan: ISIJ Int., 2002, vol. 42, pp. 717-725.

H. Lei, K. Nakajima and J.-C. He: ISIJ Int., 2010, vol. 50, pp. 1735-1745.

H. Arai, K. Matsumoto, S. Shimasaki and S. Taniguchi: ISIJ Int., 2009, vol. 49, pp. 965-974.

R. Hamzaoui, O. Elkedim, N. Fenineche, E. Gaffet and J. Craven: Mater. Sci. Eng. A, 2003, vol. 360, pp. 299-305.

R. Hamzaoui, O. Elkedim and E. Gaffet: Mater Sci Eng A, 2004, vol. 381, pp. 363-371.

R. Hamzaoui and O. Elkedim: J. Alloys Comp., 2013, vol. 573, pp. 157-162.

J. F. Li, W. Q. Jie, G. C. Yang and Y. H. Zhou: Acta Mater., 2002, vol. 50, pp. 1797-1807.

T. Zeng: J. Alloys Compd. 2019. https://doi.org/10.1016/j.jallcom.2017.08.285.

N. Nakada: Mater. Let., 2017, vol. 187, pp. 166-169.

L. Zhao, N. Park, Y. Tian, A. Shibata, and N. Tsuji: Adv. Eng. Mater., vol. 19, 2017. https://doi.org/10.1002/adem.201600778

A. V. Karasev and H. Suito: ISIJ Int., 2008, vol. 48, pp. 1507-1516.

J.-O. Andersson, T. Helander, L. Hoglund, P. Shi, and B. Sundman: CALPHAD, 2002, vol. 26, pp. 273-312.

TCFE9: TCS Steels/Fe-Alloys Database Version 9.0, Thermo-Calc Software AB, Sweden, 2017.

A. V. Karasev and H. Suito: ISIJ Int., 2009, vol. 49, pp. 229-238.

H. Suito, A. V. Karasev, M. Hamada, R. Inoue and K. Nakajima: ISIJ Int., 2011, vol. 51, pp. 1151-1162.

C. Xuan, H. Shibata, S. Sukenaga, P. G. Jönsson and K. Nakajima: ISIJ Int., 2015, vol. 55, pp. 1882-1890.

K. Ogino, K. Nogi and Y. Koshida: Tetsu-to-Hagané, 1973, vol. 59, pp. 1380-1387.

J. M. Humenik and W. D. Kingery: J. Am. Cera. Soc., 1954, vol. 37, pp. 18-23.

P. A. Kralchevsky, V. N. Paunov, N. D. Denkov, I. B. Ivanov and K. Nagayama: J. Colloid Interface Sci., 1993, vol. 155, pp. 420-437.

V. N. Paunov, P. A. Kralchevsky, N. D. Denkov and K. Nagayama: J. Colloid Interface Sci., 1993, vol. 157, pp. 100-112.

C. J. Xuan and W. Mu: J. Mater. Sci. 2019. https://doi.org/10.1007/s10853-019-03458-z.

Acknowledgment

CX would like to acknowledge Docent Andrey Karasev and Professor Pär Jönsson at KTH Royal Institute of Technology for the assistance of sample preparation. WM would like to acknowledge the financial support from The Swedish Foundation for International Cooperation in Research and Higher Education (STINT).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted May 12, 2019.

Appendix

Appendix

See Figure A1.

Rights and permissions

About this article

Cite this article

Mu, W., Xuan, C. Agglomeration Mechanism of Complex Ti-Al Oxides in Liquid Ferrous Alloys Considering High-Temperature Interfacial Phenomenon. Metall Mater Trans B 50, 2694–2705 (2019). https://doi.org/10.1007/s11663-019-01686-x

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-019-01686-x