Abstract

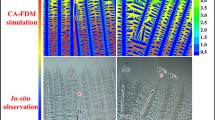

A three-dimensional (3D) quantitative cellular automaton (CA) model was developed to simulate dendritic growth during solidification processing of ternary alloys. A detailed method was proposed to solve solute diffusion and calculate the solid fraction for ternary alloys during solidification. The present model has been shown to accurately predict dendrite morphologies and solute distributions of both single equiaxed dendrite and columnar dendrites during solidification. The model was also used to study the influence of the concentration of a third component (Mg in the Al-Si-Mg system) on dendritic growth. With increasing Mg concentration, the steady-state dendrite tip growth velocity was shown to decrease, resulting in a shorter primary dendrite length. The 3D CA simulation results agree well with the prediction of the LGK theoretical model. Multi-columnar dendrite growth was simulated with different cooling rates. Primary and secondary dendrite morphology was shown to have little variation at low cooling rates (1.0 to 2.0 K/s) and a constant undercooling. The average secondary dendrite arm spacing was shown to decrease with the increase of cooling rate within this range. The 3D CA simulation results are in good agreement with the experimental directional solidification experiments of a commercial A356 (Al-7 wt pct Si-0.3 wt pct Mg).

Similar content being viewed by others

References

1 S.A. David, S.S. Babu, and J.M. Vitek: Trans. JWRI., 1996, vol. 25, pp. 127–43.

2 W. Tan, S. Wen, N. Bailey, and Y.C. Shin: Metall. Mater. Trans. B, 2011, vol. 42, pp. 1306–18.

3 M.F. Zhu and C.P. Hong: Metall. Mater. Trans. A, 2004, vol. 35, pp. 1555–63.

4 D. Apelian: JOM, 2008, vol. 60, pp. 9–10.

5 M. Li: JOM, 2011, vol. 63, p. 14.

6 A.G. Murphy, D.J. Browne, W.U. Mirihanage, and R.H. Mathiesen: Acta Mater., 2013, vol. 61, pp. 4559–71.

7 G. Salloum-Abou-Jaoude, G. Reinhart, H. Combeau, M. Založnik, T.A. Lafford, and H. Nguyen-Thi: J. Cryst. Growth, 2015, vol. 411, pp. 88–95.

8 W. Wang, P.D. Lee, and M. McLean: Acta Mater., 2003, vol. 51, pp. 2971–87.

9 S. Luo and M.Y. Zhu: Comput. Mater. Sci., 2013, vol. 71, pp. 10–8.

10 M.F. Zhu and D.M. Stefanescu: Acta Mater., 2007, vol. 55, pp. 1741–55.

11 D. Tourret, Y. Song, A.J. Clarke, and A. Karma: Acta Mater., 2017, vol. 126, p. 576.

12 A. Choudhury, K. Reuther, E. Wesner, A. August, B. Nestler, and M. Rettenmayr: Comput. Mater. Sci., 2012, vol. 55, pp. 263–8.

13 A. Pineau, G. Guillemot, D. Tourret, A. Karma, and C.A. Gandin: Acta Mater., 2018, vol. 155, pp. 286–301.

14 M. Rappaz and C.A. Gandin: Acta Metall. Mater., 1993, vol. 41, pp. 345–60.

15 L. Nastac: Acta Mater., 1999, vol. 47, pp. 4253–62.

16 H.B. Dong and P.D. Lee: Acta Mater., 2005, vol. 53, pp. 659–68.

17 R. Han, S. Lu, W. Dong, D. Li, and Y. Li: J. Cryst. Growth, 2015, vol. 431, pp. 49–59.

18 W. Tan and Y.C. Shin: Comput. Mater. Sci., 2015, vol. 98, pp. 446–58.

S Ghosh, L Ma, N Ofori-Opoku, JE Guyer: Model. Simul. Mater. Sci. Eng. 1:1–10. DOI: 10.1088/1361-651x/aa7369.

20 S. Pan and M. Zhu: Acta Mater., 2010, vol. 58, pp. 340–52.

W. Wang, S. Luo, and M. Zhu (2016) Metall. Mater. Trans. A Phys. Metall. Mater. Sci., vol. 47, pp. 1355–66.

W. Wang, S. Luo, and M. Zhu (2016) Metall. Mater. Trans. A Phys. Metall. Mater. Sci., vol. 47, pp. 1339–54.

23 S. Chen, G. Guillemot, and C.A. Gandin: Acta Mater., 2016, vol. 115, pp. 448–67.

24 M. Eshraghi, S.D. Felicelli, and B. Jelinek: J. Cryst. Growth, 2012, vol. 354, pp. 129–34.

25 M.F. Zhu, W. Cao, S.L. Chen, C.P. Hong, and Y.A. Chang: J. Phase Equilibria Diffus., 2007, vol. 28, pp. 130–8.

26 R. Chen, Q. Xu, and B. Liu: Comput. Mater. Sci., 2015, vol. 105, pp. 90–100.

27 S.C. Michelic, J.M. Thuswaldner, and C. Bernhard: Acta Mater., 2010, vol. 58, pp. 2738–51.

28 X. Zhang, J. Zhao, H. Jiang, and M. Zhu: Acta Mater., 2012, vol. 60, pp. 2249–57.

29 X.F. Zhang and J.Z. Zhao: J. Cryst. Growth, 2014, vol. 391, pp. 52–8.

30 C. Gu, Y. Wei, X. Zhan, and Y. Li: Sci. Technol. Weld. Join., 2017, vol. 22, pp. 47–58.

K.C.H. Kumar, N. Chakraborti, H. Lukas, O. Bodak, and L. Rokhlin: Ternary Alloy Syst. - Phase Diagrams, Crystallogr. Thermodyn. Data Light Met. Syst. Part 3 Sel. Syst. from Al-Fe-V to Al-Ni-Zr, 2005, pp. 165–77.

32 M. Zhu, Z. Li, D. An, Q. Zhang, and T. Dai: ISIJ Int., 2014, vol. 54, pp. 384–91.

33 L. Beltran-Sanchez and D.M. Stefanescu: Metall. Mater. Trans. A, 2004, vol. 35, pp. 2471–85.

34 J. Lipton, M.E. Glicksman, and W. Kurz: Metall. Trans. A, 1987, vol. 18, pp. 341–5.

35 J. Lipton, M.E. Glicksman, and W. Kurz: Mater. Sci. Eng., 1984, vol. 65, pp. 57–63.

36 A. Karma and W.-J. Rappel: Phys. Rev. E, 1997, vol. 57, p. 4323.

37 A. Kermanpur, N. Varahraam, E. Engilehei, M. Mohammadzadeh, and P. Davami: Mater. Sci. Technol., 2000, vol. 16, pp. 579–86.

Acknowledgment

The authors would like to acknowledge the National Science Foundation for supporting this work (Award CMMI-1432688).

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted September 13, 2018.

Rights and permissions

About this article

Cite this article

Gu, C., Ridgeway, C.D. & Luo, A.A. Examination of Dendritic Growth During Solidification of Ternary Alloys via a Novel Quantitative 3D Cellular Automaton Model. Metall Mater Trans B 50, 123–135 (2019). https://doi.org/10.1007/s11663-018-1480-8

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-018-1480-8