Abstract

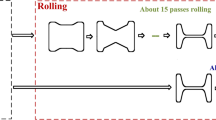

Center quality control is a key issue affecting large-section bloom production and product quality. The central convex roll could avoid the bloom side part and yield a high reduction amount, which benefit the implement of heavy reduction (HR) for bloom continuous casting process without upgrading the mechanical and hydraulic system of withdrawal and straightening machine. In this work, a curving surface convex roll (CSC-Roll), which could significantly improve bloom center quality, was designed by finite element simulation for a 360 mm × 450 mm #45 steel continuous casting bloom. The optimal roll surface shape of the CSC-Roll was determined based on an analysis of the distribution of the reduction amount in the bloom center and the strain of the bloom centerline and inner surface. The calculation results showed that the optimal size of the CSC-Roll was 200 mm in convex platform region length, 30 mm in convex platform region height, and 80 mm in gradient curvature region length. The bloom heat transfer and deformation behavior in the CSC-Roll reduction process were then analyzed. The results showed that in the CSC-Roll HR process, 61.71 pct of the reduction amount could be transmitted to the inner side of the porosity zone. Macrographs of the 360 mm × 450 mm #45 steel continuous casting bloom proved that the bloom center quality was significantly improved after CSC-Roll HR was applied.

Similar content being viewed by others

References

A. Loucif, E.B. Fredj, N. Harris, D. Shahriari, M. Jahazi and L.P. Lapierre-Boire: Metall. Mater. Trans. B, 2018, vol. 49, pp. 1046-55.

H.B. Sun and J.Q. Zhang: Metall. Mater. Trans. B, 2014, vol. 45, pp. 936-46.

B. Petrus, K. Zheng, X. Zhou, B.G. Thomas and J. Bentsman: Metall. Mater. Trans. B, 2011, vol. 42, pp. 87-103.

K. Ayata, H. Mori, K. Taniguchi and H. Matsuda: ISIJ Int., 1995, vol. 35, pp. 680-5.

D.B. Jiang and M.Y. Zhu: Metall. Mater. Trans. B, 2017, vol. 48, pp. 444-55.

S. Ogibayashi, M. Kobayashi, M. Yamada and T. Mukai: ISIJ Int., 1991, vol. 31, pp. 1400-7.

H. Preßlinger, S. Ilie, P. Reisinger, A. Schiefermüller, A. Pissenberger, E. Parteder and C. Bernhard: ISIJ Int., 2006, vol. 46, pp. 1845-51.

R. Thome and K. Harste: ISIJ Int., 2006, vol. 46, pp. 1839-44.

C.H. Moon, K.S. Oh, J.D. Lee, S.J. Lee and Y. Lee: ISIJ Int., 2012, vol. 52, pp. 1266-72.

C. Ji, S. Luo and M.Y. Zhu: ISIJ Int., 2014, vol. 54, pp. 504-10.

H. Tomono, Y. Hitomi, S. Ura, A. Teraguchi, K. Iwata and K. Yasumoto: Trans. Iron Steel Inst. Jpn., 1984, vol. 24, pp. 917-22.

Y. Meng and B.G. Thomas: Metall. Mater. Trans. B, 2003, vol. 34, pp. 685-705.

X.K. Zhao, J.M. Zhang, S.W. Lei and Y.N. Wang: Steel Res. Int., 2014, vol. 85, pp. 1533-43.

C. Ji, C.H. Wu and M.Y. Zhu: JOM, 2016, vol. 68, pp. 3107-15.

S. Nabeshima, H. Nakato, T. Fujii, T. Fujimura, K. Kushida and H. Mizota: ISIJ Int., 1995, vol. 35, pp. 673-9.

Q.P. Dong, J.M. Zhang, B. Wang and X.K. Zhao: J. Mater. Process. Technol., 2016, vol. 238, pp. 81-8.

J.P. Zhao, L. Liu, W.W. Wang, W.J. Zhou and H. Lu: Ironmaking Steelmaking, 2017, vol. 44, pp. 1-8.

X.K. Zhao, J.M. Zhang, S.W. Lei and Y.N. Wang: Steel Res. Int., 2014, vol. 85, pp. 645-58.

Z.G. Xu, X.H. Wang and M. Jiang: Steel Res. Int., 2017, vol. 88, pp. 231-42.

M Okimori, R Nishihara, S Fukunaga, and Y Okamioto: Tetsu-to-Hagane, 1994, vol. 80, pp. T120-3.

M. Takubo, Y. Matsuoka, Y. Miura, H. Higashi and S. Kittaka: The METEC and 2nd ESTAD. Session, 2015, pp. 307–18.

J. K. Brimacombe and K. Sorimachi: Metall. Trans. B, 1977, vol. 8, pp. 489-505.

C.S. Li and B.G. Thomas: Metall. Mater. Trans. B, 2004, vol. 35, pp. 1151-72.

C.H. Wu, C. Ji and M.Y. Zhu: Metall. Mater. Trans. B, 2018, vol. 49, pp. 1346-59.

S.P. Dudra and Y.T. Im: Int. J. Mach. Tools. Manuf, 1990, vol. 30, pp. 65-75.

Y.S. Lee, S.U. Lee, C. Vantyne, B.D. Joo and Y.H. Moon: J. Mater. Process. Technol, 2011, vol. 211, pp. 1136-45.

J.J. Park: Met. Mater. Int., 2011, vol. 19, pp.259-65.

J.J. Park: ISIJ Int., 2013, vol. 53, pp. 1420-6.

Y.M. Won, T.J. Yeo, K.H. Oh, J.K. Park, J. Choi and C.H. Yim: ISIJ Int., 1998, vol. 38, pp. 53-62.

E. Takeuchi and J.K. Brimacombe: Metall. Trans. B, 1984, vol. 15, pp. 493-509.

J.E. Lait, J.K. Brimacombe and F. Weinberg: Ironmaking Steelmaking, 1974, vol. 1, pp. 90-7.

I. Jimbo and A.W. Cramb: Metall. Trans. B, 1993, vol. 24, pp. 5-10.

M. Uehara, I.V. Samarasekera, and J.K. Brimacombe: Ironmaking Steelmaking, 1986, vol. 13, pp. 138-53.

C.H. Wu, C. Ji and M.Y. Zhu: Steel Res. Int., 2017, vol. 88, pp. 1600514.

T. Nozaki, J. Matsuno, K. Murata, H. Ooi, K. Kodama, Tetsu-to-Hagane, 1976, vol. 62, pp. 1503-12.

S. Koric and B.G. Thomas: J. Mater. Process. Technol., 2008, vol. 197, pp. 408-18.

P.F. Kozlowski, B.G. Thomas, J.A. Azzi and H. Wang: Metall. Mater. Trans. A, 1992, vol. 23, pp. 903-18.

C. Ji, Z.L. Wang, C.H. Wu and M.Y. Zhu: Metall. Mater. Trans. B, 2018, vol. 49, pp. 767-82.

Acknowledgments

The present work is financially supported by the National Key Research and Development Program of China (No. 2017YFB0304502), the National Natural Science Foundation of China (Nos. 51474058 and U1560208), the Program for Liaoning Excellent Talents in University (LJQ2015036) and the Fundamental Research Funds for the Central Universities of China (N172504024).

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted August 4, 2018.

Rights and permissions

About this article

Cite this article

Ji, C., Li, G., Wu, C. et al. Design and Application of CSC-Roll for Heavy Reduction of the Bloom Continuous Casting Process. Metall Mater Trans B 50, 110–122 (2019). https://doi.org/10.1007/s11663-018-1468-4

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-018-1468-4