Abstract

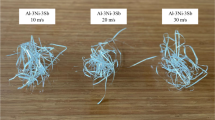

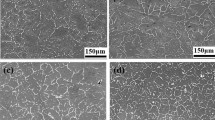

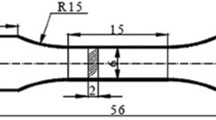

The formation mechanism of nanoscale Al3Fe phase in Al-1Fe (wt pct) alloy during rheo-extrusion was investigated, and the mechanical property of the prepared alloy was also measured. The results show that the average length of Al3Fe phase in Al-1Fe alloy prepared by rheo-extrusion is 300 nm, which is much more refined than the needlelike Al3Fe phase in as-cast Al-1Fe alloy (50 μm). In rheo-extrusion, Al3Fe phase formed by eutectic reaction is bonelike, but it could be continuously refined by the shear deformation in the wheel groove, in equal channel angular flow, and in expansion extrusion mold. The total equivalent strain of the shear deformation is higher than 4.82. The tensile strength and elongation of Al-1Fe alloy prepared by rheo-extrusion are 135 MPa and 30 pct, respectively. The tensile strength of Al-1Fe alloy prepared by rheo-extrusion is 58.8 pct higher than that of as-cast Al-1Fe alloy, and the elongation is 19 pct higher than that of as-cast Al-1Fe alloy. Compared with as-cast Al-1Fe alloy, the improvements of tensile strength and elongation caused by shear deformation in rheo-extrusion are higher than the reported improvements induced by rare earth modification.

Similar content being viewed by others

References

K.L. Sahoo and C.S. Sivaramakrishnan: Scripta Mater., 2003, vol. 99, pp. 253–57.

R.G. Guan, Y.F. Shen, Z.Y. Zhao, and X. Wang: J. Mater. Sci. Technol., 2016, vol. 33, pp. 215–23.

Q.R. Zhao, Z. Qian, X.L. Cui, Y.Y. Wu, and X.F. Liu: J. Alloys Compd., 2015, vol. 650, pp. 768–76.

P. Zhang, Z.M. Li, B.L. Liu, and W.J. Ding: J. Mater. Sci. Technol., 2017, vol. 33, pp. 367–78.

P. Moldovan, G. Popescu, and F. Miculescu: J. Mater. Process. Technol., 2004, vol. 153, pp. 408–15.

S.B. Sun, L.J. Zheng, J.H. Liu, and H. Zhang: J. Mater. Sci. Technol., 2017, vol. 33, pp. 389–96.

V.V. Tcherdyntsev, S.D. Kaloshkin, D.V. Gunderov, E.A. Afonina, I.G. Brodova, V.V. Stolyarov, Y.V. Baldokhin, E.V. Shelekhov, and I.A. Tomilin: Mater. Sci. Eng. A, 2004, vol. 375, pp. 888–93.

J.M. Cubero-Sesin and Z. Horita: Metall. Mater. Trans. A, 2012, vol. 43A, pp. 5182–92.

Z.M. Shi, K. Gao, Y.T. Shi, and Y. Wang: Mater. Sci. Eng. A, 2015, vol. 632, pp. 62–71.

D. Holland-Moritz, J. Schroers, D.M. Herlach, B. Grushko, and K. Urban: Acta Mater., 1998, vol. 46, pp. 1601–15.

C.Y. Ban, J.F. Zhang, P. Qian, X. Zhang, Y. Han, and J.Z. Cui: China Foundry, 2011, vol. 8, pp. 386–91.

S.D. Kaloshkin, V.V. Tcherdyntsev, I.A. Tomilin, D.V. Gunderov, V.V. Stolyarov, Y.V. Baldokhin, I.G. Brodova, and E.V. Shelekhov: Mater. Trans., 2002, vol. 43, pp. 2031–38.

T. Dorin, N. Stanford, N. Birbilis, and R.K. Gupta: Corros. Sci., 2015, vol. 100, pp. 396–403.

S.S. Nayak, B.S. Murty, and S.K. Pabi: J. Mater. Sci., 2008, vol. 31, pp. 449–54.

L. Li, Y.D. Zhang, C. Esling, H.X. Jiang, Z.H. Zhao, Y.B. Zuo, and J.Z. Cui: J. Cryst. Growth, 2012, vol. 339, pp. 61–69.

G.F. Mi, C.F. Dong, and D.W. Zhao: Front. Manuf. Des. Sci., 2011, vols. 44–47, pp. 2126–30.

Y. Zhang, Y.C. Liu, Y.J. Han, C. Wei, and Z.M. Gao: J. Alloys Compd., 2009, vol. 473, pp. 442–45.

O.N. Senkov, F.H. Froes, V.V. Stolyarov, R.Z. Valiev, and J. Liu: Scripta Mater., 1998, vol. 38, pp. 1511–16.

J. Hu, J. Teng, X. Ji, X. Kong, F. Jiang, and H. Zhang: J. Mater. Eng. Perform., 2016, vol. 25, pp. 4769–75.

V.V. Stolyarov, R. Lapovok, I.G. Brodova, and P.F. Thomson: Mater. Sci. Eng. A, 2003, vol. 357, pp. 159–67.

Y.F. Shen, R.G. Guan, Z.Y. Zhao, and R.D.K. Misra: Acta Mater., 2015, vol. 100, pp. 247–55.

N. Su, R.G. Guan, X. Wang, Y.X. Wang, W.S. Jiang, and H.N. Liu: J. Alloys Compd., 2016, vol. 680, pp. 283–90.

Y.X. Wang, R.G. Guan, D.W. Hou, Y. Zhang, W.S. Jiang, and H.N. Liu: J. Mater. Sci., 2017, vol. 52, pp. 1137–48.

S. Miyazaki, A. Kawachi, S. Kumai, and A. Sato: Mater. Sci. Eng. A, 2005, vol. 400, pp. 294–99.

W. Wei, W. Zhang, K.X. Wei, Y. Zhong, G. Cheng, and J. Hu: Mater. Sci. Eng. A, 2009, vol. 516, pp. 111–18.

J.R. Cho and H.S. Jeong: J. Mater. Process. Technol., 2001, vol. 110, pp. 53–60.

J. Lu, N. Saluja, A.L. Riviere, and Y. Zhou: J. Mater. Process. Technol., 1999, vol. 79, pp. 200–12.

V.M. Segal: Mater. Sci. Eng. A, 1999, vol. 271, pp. 322–33.

N. Pardis, B. Talebanpour, R. Ebrahimi, and S. Zomorodian: Mater. Sci. Eng. A, 2011, vol. 528, pp. 7537–40.

Acknowledgments

The authors are thankful for the support of the National Natural Science Foundation of China under Grant Nos. 51474063 and 51674077 and the Fundamental Research Funds for the Central Universities under Grant No. N150204016.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted August 5, 2017.

Rights and permissions

About this article

Cite this article

Wang, X., Guan, RG. & Wang, Y. Formation Mechanism of Nanoscale Al3Fe Phase in Al-Fe Alloy During Semisolid Forming Process. Metall Mater Trans B 49, 2225–2231 (2018). https://doi.org/10.1007/s11663-018-1323-7

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-018-1323-7