Abstract

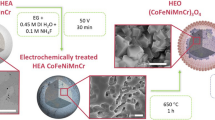

Large-scale deployment of MAX-phased Ti-Al-C with intriguing mechanical and physicochemical properties is significantly retarded by its harsh preparation conditions, in which costly precursors, high temperature and non-atmospheric pressure are generally imperative. We herein report an efficient electrolytic preparation of MAX-phased Ti-Al-C by direct electro-reduction of solid TiO2-Al2O3-C in molten CaCl2 at 1223 K under normal pressure. Homogeneous layered Ti3AlC2 with an oxygen content of 4300 ppm is prepared under a voltage of 3 V between the solid cathode and graphite anode for only 4 hours. The electro-reduction of TiO2-Al2O3-C exhibits a much faster speed compared with the electrolysis employing TiO2, TiO2-C and TiO2-Al2O3 as the precursors. Time-dependent electrolysis indicates that TiCxOy is the main intermediate. The generation of refractory and highly conducting TiCxOy intermediate enhances the reduction. Density functional theory simulations show a weak affinity towards oxygen of the resulting Ti3AlC2, which is beneficial to fast and thorough deoxidation. The formation of a layered structure of Ti3AlC2 is attributed to the template effect of the precursory graphite. By simply varying the precursory stoichiometry, layered Ti2AlC is also prepared. The present protocol featuring affordable feedstock, low temperature, ambient pressure, high energy efficiency and controllable stoichiometry is promising for large-scale application.

Similar content being viewed by others

Change history

10 July 2018

The section “Acknowledgments” was incorrect in the original article. The correct section “Acknowledgments” is given below.

References

P. Eklund, M. Beckers, U. Jansson, H. Högberg, and L. Hultman: Thin Solid Films, 2010, vol. 518, pp. 1851-1878.

M. Radovic and M.W. Barsoum: Am. Ceram. Soc. Bull., 2013, vol. 92, pp. 20-27.

L. Peng: J. Am. Ceram. Soc., 2007, vol. 90, pp. 1312-1314.

E. Wu and E. Herold Kisi: J. Am. Ceram. Soc., 2006, vol. 89, pp. 710-713.

D.J. Tallman, B. Anasori, and M.W. Barsoum: Mater. Res. Lett., 2013, vol. 1, pp. 115-125.

N.V. Tzenov and M.W. Barsoum: J. Am. Ceram. Soc., 2000, vol. 83, pp. 825-832.

M.W. Barsoum: Prog. Solid State Chem., 2000, vol. 28, pp. 201-281.

M.W. Barsoum and M. Radovic: Ann. Rev. Mater. Res., 2011, vol. 41, pp. 195-227.

X. Wang and Y. Zhou: Corros. Sci., 2003, vol. 45, pp. 891-907.

W. Wang, V. Gauthier-Brunet, G. Bei, G. Laplanche, J. Bonneville, A. Joulain, and S. Dubois: Mater. Sci. Eng., A, 2011, vol. 530, pp. 168-173.

M.R. Lukatskaya, O. Mashtalir, C.E. Ren, Y. Dall’Agnese, P. Rozier, P.L. Taberna, M. Naguib, P. Simon, M.W. Barsoum, and Y. Gogotsi: Science, 2013, vol. 341, pp. 1502-1505.

P. Yan, R. Zhang, J. Jia, C. Wu, A. Zhou, J. Xu, and X. Zhang: J. Power Sources 2015, vol. 284, pp. 38-43.

M. Hu, Z. Li, H. Zhang, T. Hu, C. Zhang, Z. Wu, and X. Wang: Chem. Commun., 2015, vol. 51, pp. 13531-13533.

B. Ding, J. Wang, Y. Wang, Z. Chang, G. Pang, H. Dou, and X. Zhang: Nanoscale, 2016, vol. 8, pp. 11136-11142.

M.R. Lukatskaya, J. Halim, B. Dyatkin, M. Naguib, Y.S. Buranova, M.W. Barsoum, and Y. Gogotsi: Angew. Chem. Int. Ed., 2014, vol. 53, pp. 4877-4880.

M. Naguib, V.N. Mochalin, M.W. Barsoum, and Y. Gogotsi: Adv. Mater., 2014, vol. 26, pp. 992-1005.

M. Naguib, J. Come, B. Dyatkin, V. Presser, P.-L. Taberna, P. Simon, M.W. Barsoum, and Y. Gogotsi: Electrochem. Commun., 2012, vol. 16, pp. 61-64.

Q. Tang, Z. Zhou, and P. Shen: J. Am. Chem. Soc., 2012, vol. 134, pp. 16909-16916.

S.S. Li, X.L. Zou, Y. Hu, X.G. Lu, X.L. Xiong, Q. Xu, H.W. Cheng and Z.F. Zhou: J. Electrochem. Soc., 2018, vol. 165, pp. E97-E107.

X. Xie, Y. Xue, L. Li, S. Chen, Y. Nie, W. Ding, and Z. Wei: Nanoscale, 2014, vol. 6, pp. 11035-11040.

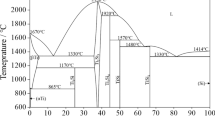

M. Pietzka and J. Schuster: J. Phase Equilibria, 1994, vol. 15, pp. 392-400.

O. Wilhelmsson, J.-P. Palmquist, E. Lewin, J. Emmerlich, P. Eklund, P.Å. Persson, H. Högberg, S. Li, R. Ahuja, and O. Eriksson: J. Cryst. Growth, 2006, vol. 291, pp. 290-300.

G.Z. Chen, D.J. Fray, and T.W. Farthing: Nature, 2000, vol. 407, pp. 361-364.

D. Wang, G. Qiu, X. Jin, X. Hu, and G.Z. Chen: Angew. Chem. Int. Ed., 2006, vol. 45, pp. 2384-2388.

K. Jiang, X. Hu, M. Ma, D. Wang, G. Qiu, X. Jin, and G.Z. Chen: Angew. Chem. Int. Ed. Engl., 2006, vol. 45, pp. 428-32.

A.M. Abdelkader, K.T. Kilby, A. Cox, and D.J. Fray: Chem. Rev., 2013, vol. 113, pp. 2863-86.

D.J. Fray and C. Schwandt: Mater. Trans., 2017, vol. 58, pp. 306-312.

D.J. Fray: Faraday Discuss., 2016, vol. 190, pp. 11-34.

A.B. Aybar and M. Anik: J. Energy Chem., 2017, vol. 26, pp. 719-723.

J. Sure, D.S.M. Vishnu and C. Schwandt: Appl. Mater. Today, 2017, vol. 9, pp. 111-121.

D.S.M. Vishnu, N. Sanil, K.S. Mohandas and K. Nagarajan: Acta Metall. Sin., 2017, vol. 30, pp. 218-227.

H. Yin, W. Xiao, X. Mao, W. Wei, H. Zhu, and D. Wang: Electrochim. Acta, 2013, vol. 102, pp. 369-374.

W. Xiao, J. Zhou, L. Yu, D. Wang and X. W. Lou: Angew. Chem. Int. Ed., 2016, vol. 55, pp. 7427-31.

X. Jin, P. Gao, D. Wang, X. Hu, and G.Z. Chen: Angew. Chem. Int. Ed., 2004, vol. 116, pp. 751-754.

T. Nohira, K. Yasuda and Y. Ito: Nat. Mater., 2003, vol. 2, pp. 397-401.

A.M. Abdelkader: J. Eur. Ceram. Soc., 2016, vol. 36, pp. 33-42.

W. Xiao and D. Wang: Chem. Soc. Rev., 2014, vol. 43, pp. 3215-3228.

A.M. Abdelkader and D.J. Fray: J. Eur. Ceram. Soc., 2012, vol. 32, pp. 4481-4487.

N.J. Lane, S.C. Vogel, E.A.N. Caspi, and M.W. Barsoum: J. Appl. Phys., 2013, vol. 113, p. 183519.

X. Wang and Y. Zhou: J. Mater. Chem., 2002, vol. 12, pp. 455-460.

Y. Zou, Z. Sun, H. Hashimoto, and S. Tada: Mater. Sci. Eng., A, 2008, vol. 473, pp. 90-95.

I.I. Ivanova, A.N. Demidik, M.V. Karpets, N.A. Krylova, A.P. Polushko and S.A. Firstov: Powder Metall. Met. Ceram., 2014, vol. 53, pp. 377-385.

D. Tang, W. Xiao, L. Tian, and D. Wang: J. Electrochem. Soc., 2013, vol. 160, pp. F1192-F1196.

L. Zhang, S. Wang, S. Jiao, K. Huang and H. Zhu: Electrochim. Acta, 2012, vol. 75, pp. 357-359.

S. Li, X. Zou, X. Lu, K. Zheng, G. Li, C. Chen, Q. Xu and Z. Zhou: J. Electrochem. Soc., 2017, vol. 164, pp. D533-D542.

X. Yan and D. J. Fray: J. Appl. Electrochem., 2009, vol. 39, pp. 1349-1360.

X. Yan: Metall. Mater. Trans. B, 2008, vol. 39, pp. 348-363.

H. Kadowaki, Y. Katasho, K. Yasuda and T. Nohira: J. Electrochem. Soc., 2018, vol. 165, pp. D83-D89.

Acknowledgment

This work was funded by the National Natural Science Foundation of China (51722404 and 51674177).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Manuscript submitted October 15, 2017.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Fan, J., Tang, D., Mao, X. et al. An Efficient Electrolytic Preparation of MAX-Phased Ti-Al-C. Metall Mater Trans B 49, 2770–2778 (2018). https://doi.org/10.1007/s11663-018-1304-x

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-018-1304-x