Abstract

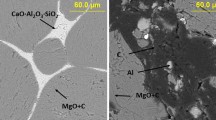

Magnesia-chromite refractory materials are widely employed in steel production, and are considered a potential MgO source for the generation of MgO·Al2O3 spinel inclusions in steel melts. In this study, a square magnesia-chromite refractory rod was immersed into molten steel of various compositions held in an Al2O3 crucibles. As the immersion time was extended, Mg and Cr gradually dissolved from the magnesia-chromite refractory, and the Mg and Cr contents of the steel melts increased. However, it was found that the inclusions in the steel melts remained as almost pure Al2O3 because the Mg content of the steel melts was low, approximately 1 ppm. On the surface of the magnesia-chromite refractory, an MgO·Al2O3 spinel layer with a variable composition was formed, and the thickness of the MgO·Al2O3 spinel layer increased with the immersion time and the Al content of the steel melts. At the rod interface, the formed layer consisted of MgO-saturated MgO·Al2O3 spinel. The MgO content decreased along the thickness direction of the layer, and at the steel melts interface, the formed layer consisted of Al2O3-saturated MgO·Al2O3 spinel. Therefore, the low content of Mg in steel melts and the unchanged inclusions were because of the equilibrium between Al2O3-saturated MgO·Al2O3 layer and Al2O3. In addition, the effects of the Al and Cr contents of the steel melts on the dissolution of Mg from the magnesia-chromite refractory are insignificant.

Similar content being viewed by others

References

K. Fujii, T. Nagasaka, and M. Hino: ISIJ Int., 2000, vol. 40, pp. 1059–1066.

W-Y. Cha, D-S. Kim, Y-D. Lee, J-J. Park: ISIJ Int., 2000, vol. 44, pp. 1134-1139.

J-H. Park, and H. Todoroki: ISIJ Int., 2010, vol. 48, pp. 1333–1346.

M. Jiang, X. Wang, B. Chen and W. Wang: ISIJ Int., 2010, vol. 48, pp. 95–104.

W. Yang, L. Zhang, X. Wang, Y. Ren, X. Liu and Q. Shan: ISIJ Int., 2013, vol. 53, pp. 1401-1410.

Y. Bi, A. V. Karasev and P. G. Jӧnsson: ISIJ Int., 2013, vol. 53, pp. 2099-2109.

T. Yoshioka, K. Nakahata, T. Kawamura, Y. Ohba: ISIJ Int., 2016, vol. 56, pp. 1973-1981.

E. Sunami, S. Nozaki, Y. Miura and T. Miura: Tetsu-to-Hagané, 1982, vol. 68, S248.

O. Suzuki, M. Ogchi, K. Nohara, T. Emi, Y. Mihara and Y. Katayama: Tetsu-to-Hagané, 1982, vol. 68, S249.

R. Nakao, H. Tsuboi, E. Takeuchi, H. Morishige, M. Miyake: Tetsu-to-Hagané, 1987, vol. 73, S941.

T. Nishi and K. Shinme: Tetsu-to-Hagané, 1998, vol. 84, pp. 837-843.

H. Matsuno and Y. Kikuchi: Tetsu-to-Hagané, 2002, vol. 88, pp. 48-50.

Y. Ehara, S. Yokoyama, M. Kawakami: Tetsu-to-Hagané, 2007, vol. 93, pp. 475-482.

Y. Ehara, S. Yokohama, M. Kawakami: Tetsu-to-Hagané, 2007, vol. 93, pp. 208-214.

Y. Kang, B. Sahebkar, P R. Scheller, K. Morita and S. Du: Metall. Mater. Trans. B, 2011, vol. 42B, pp. 522–534

J.H. Park, S.B. Lee and H.R. Gaye: Metall. Mater. Trans. B, 2008, vol. 39B, pp. 853–861

C.W. Seo, S.H. Kim, S.K. Jo, M.O. Suk and S.M. Byun: Metall. Mater. Trans. B, 2010, vol. 41B, pp. 790–797

J.H. Park: Metall. Mater. Trans. B, 2007, vol. 38B, pp. 657–663

J.H. Park: Metall. Mater. Trans. B, 2005, vol. 36B, pp. 495–502

S.K. Jo, B. Song and S.H. Kim: Metall. Mater. Trans. B, 2002, vol. 41B, pp. 703–709

H. Itoh, M. Hino and S. Ban-ya: Metall. Mater. Trans. B, 1997, vol. 28B, pp. 953–956

G. Okuyama, K. Yamaguchi, S. Takeuchi, and K. Sorimachi: ISIJ Int., 2000, vol. 40, pp. 121–128

A Harada, G Miyano, N Maruoka, H Shibata, S KIitamura (2014) ISIJ Int. 54:2230–38

V. Brabie: ISIJ Int., 1996, vol. 36, S109-S112

C. Liu, F. Huang, J. Suo, and X. Wang: Metall. Mater. Trans. B, 2016, vol. 47B, pp. 989–998

C. Liu, F. Huang, and X. Wang: Metall. Mater. Trans. B, 2016, vol. 47B, pp. 999–1009

M. K. Haldar, H. S. Tripathi, S. K. Das and A. Ghosh: Ceramics Int., 2004, vol. 30, pp. 911-915

A. Ikesue, K. Shimizu, K. Morikawa and J. Yoshitomi: J. Ceram. Soc. Jpn, (2003), vol. 111, pp. 407-412

K. Goto: Resource Geology, 1997, vol. 47, pp. 223-229

Verein Deutscher Eisenhuttenleute: Slag Atlas, 2nd ed., Verlag Stahleisen GmbH, Dusseldorf, Germany, 1995, p. 44

M. Hino and K. Ito, Thermodynamic Data for Steelmaking, Tohoku University Press, Sendai, Japan, 2009.

M. Hino, K. Higuchi, T. Nagasaka and S. Ban-ya: Tetsu-to-Hanagé, 1994, vol. 80, pp. 501-506

K. Morita, A. Inoue, N. Takayama and N. Sano: Tetsu-to-Hagané, 1988, vol. 74, pp. 999-1005

K.T. Jacob and C. K. Behera: Metall. Mater. Trans. B, 2000, vol. 31B, pp. 1323-1332

Sung-koo Jo, B. Song and S-H. Kim: Metall. Mater. Trans. B, 2002, vol. 33B, pp. 703–709.

M. Kishi, R. Inoue, and H. Suito: Iron Steel Inst. Jpn. Int., 1994, vol. 34, pp. 859-67.

Y. Nakamura and M. Uchimura: Trans. Iron Steel Inst. Jpn., 1973, vol. 13, pp. 343-49.

The Japan Society for Promotion of Science, the 19th Committee on Steelmaking, Thermodynamic Data for Steelmaking, Gordon and Breach Science Publishers, 1988.

H. Itoh, M. Hino and S. Ban-ya: Tetsu-to-Hagané, 1997, vol. 83, pp. 623–628

H. Ohta and H.Suito: Metall. Mater. Trans. B, 1997, vol. 28B, pp. 1131–1139

Acknowledgments

The authors thank Professor Xinhua Wang of the Shougang Corporation (previously at the University of Science and Technology, Beijing) for his kind support in the P-SEM analysis. The authors appreciate the Kurosaki-Harima Corporation for supplying the magnesia-chromite refractory rod. The authors gratefully acknowledge the financial support provided by the Iron & Steel Institute of Japan (ISIJ) research promotion Grant.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted September 26, 2017.

Rights and permissions

About this article

Cite this article

Liu, C., Yagi, M., Gao, X. et al. Dissolution Behavior of Mg from Magnesia-Chromite Refractory into Al-killed Molten Steel. Metall Mater Trans B 49, 2298–2307 (2018). https://doi.org/10.1007/s11663-018-1301-0

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-018-1301-0