Abstract

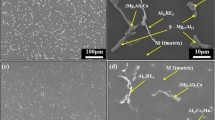

As a new microstructure refining method, accumulative continuous extrusion forming (ACEF) cannot only refine metal matrix but also refine the phases that exist in it. In order to detect the refinements of grain and second phase during the process, Al-1Fe (wt pct) alloy was processed by ACEF, and the microstructural evolution was analyzed by electron backscatter diffraction (EBSD) and transmission electron microscopy (TEM). Results revealed that the average grain size of Al-1Fe (wt pct) alloy decreased from 13 to 1.2 μm, and blocky Al3Fe phase with an average length of 300 nm was granulated to Al3Fe particle with an average diameter of 200 nm, after one pass of ACEF. Refinement of grain was attributed to continuous dynamic recrystallization (CDRX), and the granulation of Al3Fe phase included the spheroidization resulting from deformation heat and the fragmentation caused by the coupling effects of strain and thermal effect. The spheroidization worked in almost the entire deformation process, while the fragmentation required strain accumulation. However, fragmentation contributed more than spheroidization. Al3Fe particle stimulated the formation of substructure and retarded the migration of recrystallized grain boundary, but the effect of Al3Fe phase on refinement of grain could only be determined by the contrastive investigation of Al-1Fe (wt pct) alloy and pure Al.

Similar content being viewed by others

References

R.T. Li, Vinod K. Murugan, Z.L. Dong, and K.A. Khor: J. Mater. Sci. Technol., 2016, vol. 32, pp. 1054–58.

V.V. Stolyarov, R. Lapovok, I.G. Brodova, and P.F. Thomson: Mater. Sci. Eng. A, 2003, vol. 357, pp. 159–67.

A. Hamid, H.E. Mohammad, and E. Rahmatollah: Acta Metall. Sin.-Engl., 2015, vol. 28, pp. 83–92.

M. Abo-Elsoud: J. Mater. Sci. Technol., 2012, vol. 28, pp. 27–33.

P. Moldovan, G. Popescu, and F. Miculescu: J. Mater. Process. Technol., 2004, vol. 153, pp. 408–15.

S.B. Sun, L.J. Zheng, J.H. Liu, and H. Zhang: J. Mater. Sci. Technol., 2017, vol. 33, pp. 389–96.

V.V. Tcherdyntsev, S.D. Kaloshkin, D.V. Gunderov, E.A. Afonina, I.G. Brodova, V.V. Stolyarov, Y.V. Baldokhin, E.V. Shelekhov, and I.A. Tomilin: Mater. Sci. Eng. A, 2004, vol. 375, pp. 888–93.

J.M. Cubero-Sesin and Z. Horita: Metall. Mater. Trans. A, 2012, vol. 43A, pp. 5182–92.

Y.L. Liu, L. Luo, C.F. Han, L.Y. Ou, J.J. Wang, and C.Z. Liu: J. Mater. Sci. Technol., 2016, vol. 32, pp. 305–12.

Q.R. Zhao, Z. Qian, X.L. Cui, Y.Y. Wu, and X.F. Liu: J. Alloy Compd., 2016, vol. 666, pp. 50–57.

J. Du, Y.T. Shi, M.C. Zhou, and W.F. Li: J. Mater. Sci. Technol., 2013, vol. 23, pp. 1297–1302.

Z.M. Shi, K. Gao, Y.T. Shi, and Y. Wang: Mater. Sci. Eng. A, 2015, vol. 632, pp. 62–71.

D. Holland-Moritz, J. Schroers, D.M. Herlach, B. Grushko, and K. Urban: Acta Mater., 1998, vol. 46, pp. 1601–15.

S.S. Nayak, B.S. Murty, and S.K. Pabi: J. Mater. Sci., 2008, vol. 31, pp. 449–54.

T. Dorin, N. Stanford, N. Birbilis, and R.K. Gupta: Corros. Sci., 2015, vol. 100, pp. 396–403.

O.N. Senkov, F.H. Froes, V.V. Stolyarov, R.Z. Valiev, and J. Liu: Scripta Mater., 1998, vol. 38, pp. 1511–16.

J.M. Hu, J. Teng, X.K. Ji, X.X. Kong, F.L. Jiang, and H. Zhang: J. Mater. Eng. Perform., 2016, vol. 25, pp. 4769–75.

J.M. Cubero-Sesin and Z. Horita: J. Mater. Sci., 2013, vol. 48, pp. 4713–22.

J.M. Cubero-Sesin and Z. Horita: Metall. Mater. Trans. A, 2012, vol. 43A, pp. 5182–92.

K. Hyoung-Wook, K. Suk-Bong, T. Nobuhiro, and M. Yoritoshi: Acta Mater., 2005, vol. 53, pp. 1737–49.

D. Azimi-Yancheshmeh and M. Aghaiekhafri: Defect Diff. Forum, 2011, vols. 312–315, pp. 166–71.

X.X. Kong, H. Zhang, and X.K. Ji: Mater. Sci. Eng. A, 2014, vol. 612, pp. 131–39.

R.G. Guan and T. Di: Acta Metall. Sin.-Engl., 2017, vol. 5, pp. 1–24.

Y.F. Shen, R.G. Guan, Z.Y. Zhao, and R.D.K. Misra: Acta Mater., 2015, vol. 100, pp. 247–55.

N. Su, R.G. Guan, X. Wang, Y.X. Wang, W.S. Jiang, and H.N. Liu: J. Alloy Compd., 2016, vol. 680, pp. 283–90.

Y.X. Wang, R.G. Guan, D.W. Hou, Y. Zhang, W.S. Jiang, and H.N. Liu: J. Mater. Sci., 2017, vol. 52, pp. 1137–48.

R.G. Guan, Y.F. Shen, Z.Y. Zhao, and X. Wang: J. Mater. Sci. Technol., 2016, vol. 33, pp. 215–23.

R.Z. Chao, X.H. Guan, R.G. Guan, D. Tie, C. Lian, X. Wang, and J. Zhang: Trans. Nonferr. Met. Soc., 2014, vol. 24, pp. 3164–69.

K.M. Zhang, J.X. Zou, J. Li, and Z.S. Yu: J. Mater. Sci. Technol., 2014, vol. 30, pp. 263–67.

ASTME112: Standard Test Methods for Determining Average Grain Size, 2010.

O. Sitdikov, T. Sakai, E. Avtokratova, R. Kaibyshev, K. Tsuzaki, and Y. Watanabe: Acta Mater., 2008, vol. 56, pp. 821–34.

S. Miyazaki, A. Kawachi, S. Kumai, and A. Sato: Mater. Sci. Eng. A, 2005, vol. 400, pp. 294–99.

W. Blum, J. Dvorak, P. Kral, P. Eisenlohr, and V. Sklenička: J. Mater. Sci. Technol., 2017, vol. 32, pp. 1309–20.

P.Y. Zhu and Q.Y. Liu: Mater. Sci. Technol., 2013, vol. 2, pp. 500–07.

L.A. Narayanan, F.H. Samuel, and J.E. Gruzleski: Metall. Mater. Trans. A, 1995, vol. 26A, pp. 2161–74.

H. Sayed and I. Kovács: Phys. Status Solidi, 2010, vol. 24, pp. 45–47.

A. Torres, S. Serna, C. Patino, and G. Rosas: Acta Metall. Sin.-Engl., 2015, vol. 28, pp. 1117–22.

P.J. Apps, J.R Bowen, and P.B. Prangnell: Acta Mater., 2003, vol. 51, pp. 2811–22.

P.J. Apps, M. Berta, and P.B. Prangnell: Acta Mater., 2005, vol. 53, pp. 499–511.

I. Nikulin, A. Kipelova, S. Malopheyev, and R. Kaibyshev: Acta Mater., 2012, vol. 60, pp. 487–97.

C.Y. Barlow, N. Hansen, and Y.L. Liu: Acta Mater., 2002, vol. 50, pp. 171–82.

T.A. Bennett, R.H. Petrov, L.A.I. Kestens, L.Z. Zhuang, and P.D. Smet: Scripta Mater., 2010, vol. 63, pp. 461–64.

F.J. Humphreys and M.G. Ardakani: Acta Mater., 1996, vol. 44, pp. 2717–27.

K. Chang, W. Feng, and L.Q. Chen: Acta Mater., 2009, vol. 57, pp. 5229–36.

L.S. Shvindlerman, E. Jannot, and G. Gottstein: Acta Mater., 2007, vol. 55, pp. 3397–3401.

J. Zhou, S.H. Zhang, X.N. Wang, B.B. Zhao, X.P. Dong, and L.T. Zhang: Scripta Mater., 2016, vol. 116, pp. 100–03.

Acknowledgments

The authors appreciate the support of the National Natural Science Foundation of China, under Grant No. 51674077, and the Fundamental Research Funds for the Central Universities, under Grant No. N150204016.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted July 27, 2017.

Rights and permissions

About this article

Cite this article

Wang, X., Guan, RG., Tie, D. et al. Microstructural Evolution of Al-1Fe (Weight Percent) Alloy During Accumulative Continuous Extrusion Forming. Metall Mater Trans B 49, 490–498 (2018). https://doi.org/10.1007/s11663-018-1185-z

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-018-1185-z