Abstract

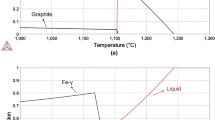

The development of high-quality semisolid raw materials requires an understanding of the phase transformations that occur as the material is heated up to the semisolid state, i.e., its melting behavior. The microstructure of the material plays a very important role during semisolid processing as it determines the flow behavior of the material when it is formed, making a thorough understanding of the microstructural evolution essential. In this study, the phase transformations and microstructural evolution in Fe2.5C1.5Si gray cast iron specially designed for thixoforming processes as it was heated to the semisolid state were observed using in situ high-temperature confocal laser scanning microscopy. At room temperature, the alloy has a matrix of pearlite and ferrite with fine interdendritic type D flake graphite. During heating, the main transformations observed were graphite precipitation inside the grains and at the austenite grain boundaries; graphite flakes and graphite precipitates growing and becoming coarser with the increasing temperature; and the beginning of melting at around 1413 K to 1423 K (1140 °C to 1150 °C). Melting begins with the eutectic phase (i.e., the carbon-rich phase) and continues with the primary phase (primary austenite), which is consumed as the temperature increases. Melting of the eutectic phase composed by coarsened interdendritic graphite flakes produced a semi-continuous liquid network homogeneously surrounding and wetting the dendrites of the solid phase, causing grains to detach from each other and producing the intended solid globules immersed in liquid.

Similar content being viewed by others

References

[1] D.B. Spencer, R. Mehrabian and M.C. Flemings: Metall. Trans., 1972, vol. 3, pp. 1925–32. doi:10.1007/BF02642580

[2] H.V. Atkinson: Prog. Mater. Sci., 2005, vol. 50, pp. 341–412. doi: 10.1016/j.pmatsci.2004.04.003

[3] M.C. Flemings: Metall. Trans. B, 1991, vol. 22, pp. 269–93. doi: 10.1007/BF02661090

[4] S. Zabler, A. Ershov, A. Rack, F. Garcia-Moreno, T. Baumbach and J. Banhart: Acta Mater., 2013, vol. 61, pp. 1244–53. doi: 10.1016/j.actamat.2012.10.047

[5] B. Cai, S. Karagadde, L. Yuan, T.J. Marrow, T. Connolley and P.D. Lee: Acta Mater., 2014, vol. 76, pp. 371–80. doi: 10.1016/j.actamat.2014.05.035

[6] T. Werz, M. Baumann, U. Wolfram and C.E. Krill III: Mater. Charact., 2014, vol. 90, pp. 185–95. doi: 10.1016/j.matchar.2014.01.022

[7] K. Du, Q. Zhu, D. Li and F. Zhang: Mater. Charact., 2015, vol. 106, pp. 134–40. doi: 10.1016/j.matchar.2015.05.035

[8] D. Phelan, N. Stanford and R. Dippenaar: Mater. Sci. Eng. A, 2005, vol. 407, pp. 127–34. doi: 10.1016/j.msea.2005.07.015

[9] D. Zhang, H. Terasaki and Y. Komizo: Acta Mater., 2010, vol. 58, pp. 1369–78. doi: 10.1016/j.actamat.2009.10.043

[10] M.M. Attallah, H. Terasaki, R.J. Moat, S.E. Bray, Y. Komizo and M. Preuss: Mater. Charact., 2011, vol. 62, pp. 760–67. doi: 10.1016/j.matchar.2011.05.001

Y. Komizo and H. Terasaki (2010) In situ study of phase transformation in steel during welding. In: T. Kannengiesser, S.S. Babu, Y. Komizo and A.J. Ramirez (Eds.), In situ studies with photons, neutrons and electrons scattering. Springer, Berlin, pp. 1–11. doi: 10.1007/978-3-642-14794-4_1

[12] I. Sohn and R. Dippenaar: Metall. Mater. Trans. B, 2016, vol. 47, pp. 2083–94. doi: 10.1007/s11663-016-0675-0

[13] G.C. Gu, R. Pesci, L. Langlois, E. Becker, R. Bigot and M.X. Guo: Acta Mater., 2014, vol. 66, pp. 118–31. doi: 10.1016/j.actamat.2013.11.075

[14] X.G. Hu, Q. Zhu, H.X. Lu, F. Zhang, D.Q. Li and S.P. Midson: J. Alloy. Compd., 2015, vol. 649, pp. 204–10. doi: 10.1016/j.jallcom.2015.07.121

S.P Midson: Solid State Phenom., 2015, vol. 217-218, pp. 487–95. doi: 10.4028/www.scientific.net/SSP.217-218.487

S.P. Midson: in Comprehensive Materials Processing, S. Hashimi, ed., Elsevier, Oxford, 2014, vol. 5, pp. 259–74. doi:10.1016/B978-0-08-096532-1.00517-3

[17] M. Tsuchiya, H. Ueno and I. Takagi: JSAE Rev., 2003, vol. 24, pp. 205–14. doi: 10.1016/S0389-4304(03)00013-4

[18] F. Pahlevani and M. Nili-Ahmadabadi: Int. J. Cast. Metal. Res., 2004, vol. 17, pp. 157–61. doi: 10.1179/136404604225020560

[19] M. Ramadan, M. Takita and H. Nomura: Mater. Sci. Eng. A, 2006, vol. 417, pp. 166–73. doi: 10.1016/j.msea.2005.10.054

[20] M. Ramadan, N. El-Bagoury, N. Fathy, M.A. Waly and A.A. Nofal: J. Mater. Sci., 2011, vol. 46, pp. 4013–19. doi: 10.1007/s10853-011-5329-7

[21] B. Abbasi-Khazaei and S. Ghaderi: J. Mater. Sci. Technol., 2012, vol. 28, pp. 946–50. doi: 10.1016/S1005-0302(12)60156-X

[22] J. Cui, H. Zhang, L. Chen, H. Li and W. Tong: Acta Metall. Sin., 2014, vol. 27, pp. 476–82. doi: 10.1007/s40195-014-0067-x

[23] A.S. Roca, H.D.C. Fals, J.A. Pedron and E.J. Zoqui: J. Mater. Process. Technol., 2012, vol. 212, pp. 1225–35. doi: 10.1016/j.jmatprotec.2012.01.012

[24] R.L. Nadal, A.S. Roca, H.D.C Fals and E.J. Zoqui: J. Mater. Process. Technol., 2015, vol. 226, pp. 146–56. doi: 10.1016/j.jmatprotec.2015.07.015

[25] A.M. Camacho, H.V. Atkinson, P. Kapranos and B.B. Argent: Acta Mater., 2003, vol. 51, pp. 2319–30. doi: 10.1016/S1359-6454(03)00040-5

ASTM A247-16a: Standard test method for evaluating the microstructure of graphite in iron castings, ASTM International, West Conshohocken, PA, 2016. Doi:10.1520/A0247-16A

ASTM E112-13: Standard test methods for determining average grain size, ASTM International, West Conshohocken, PA, 2013. doi:10.1520/E0112

[28] G.L Rivera, R.E. Boeri and J.A. Sikora: Scr. Mater., 2004, vol. 50, pp. 331–35. doi: 10.1016/j.scriptamat.2003.10.019

D.M. Stefanescu: in Properties and Selection: Irons, Steels and High Performance Alloys, ASM Handbook, ASM International, 1990, vol. 1, pp. 3–11. ISBN: 978-0-87170-377-4

[30] W. Xue and Y. Li: J. Alloy. Compd., 2016, vol. 689, pp. 408–15. doi: 10.1016/j.jallcom.2016.07.052

[31] K. Nakajima, M. Apel and I. Steinbach: Acta Mater., 2006, vol. 54, pp. 3665–72. doi: 10.1016/j.actamat.2006.03.050

[32] D. Liu, H.V. Atkinson and H. Jones: Acta Mater., 2005, vol. 53, pp. 3807–19. doi: 10.1016/j.actamat.2005.04.028

P.J. Uggowitzer and D.I. Uhlenhaut: in Thixoforming: Semi-solid Metal Processing, G. Hirt and R. Kopp, eds., Wiley-VCH, Weinheim, 2009, pp. 29–42. doi:10.1002/9783527623969.ch2

[34] C.A. Schneider, W.S. Rasband and K.W. Eliceiri: Nat. Methods, 2012, vol. 9, pp. 671–75. doi: 10.1038/nmeth.2089

[35] H. Wabusseg, G.C. Gullo, P.J. Uggowitzer, K. Steinhoff and H. Kaufmann: J. Mater. Sci., 2002, vol. 37, pp. 1173–78. doi: 10.1023/A:1014315421781

Acknowledgments

This study was supported by São Paulo Research Foundation—FAPESP under Grant Numbers 2011/19997-0 and 2015/06965-3. The authors would like to thank IMBIL Industry and Maintenance of Pumps ITA Ltda. for producing the cast iron and the Joining and Welding Research Institute, Osaka University, and the School of Mechanical Engineering, University of Campinas—UNICAMP, for providing the necessary facilities.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted December 20, 2016.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Supplementary material 1 (MP4 22960 kb)

Rights and permissions

About this article

Cite this article

Benati, D.M., Ito, K., Kohama, K. et al. Study on the Microstructure and Liquid Phase Formation in a Semisolid Gray Cast Iron. Metall Mater Trans B 48, 2293–2303 (2017). https://doi.org/10.1007/s11663-017-1018-5

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-017-1018-5